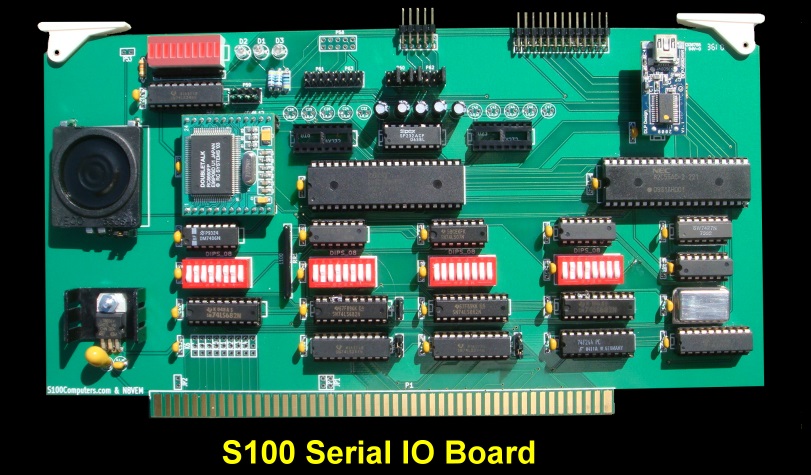

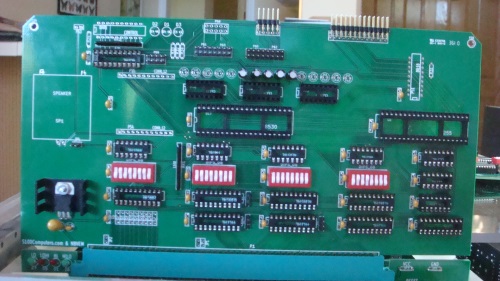

Serial IO Board Version V3.1

The demand for this board has been quite large. A

third version of this board was laid out. This version is called V3.1. The

first batch was made by PCBCart in Jan 2016. It is

identical to the above V2 board except that a

more detailed Silkscreen was drawn up. This one has labels over all the

IC's, and better legends over the switches and connectors.

The KiCAD and related files are presented below.

BUGS V3.1

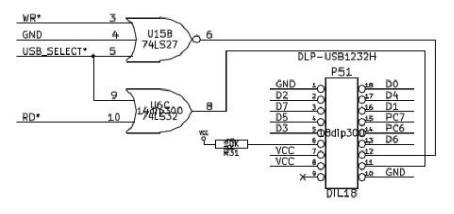

Wayne Warthen, pointed out that the default EEPROM mode for the newer

USB1232H "chip" is set for a mode other than

FIFO. This requires the board to be re-programmed using FTDIs tool

T_Prog utility

(http://www.ftdichip.com/Support/Utilities.htm#FT_Prog) to

make the FIFO mode work as described above. The older USB245R

"chip" does not require this modification and works as described

above.

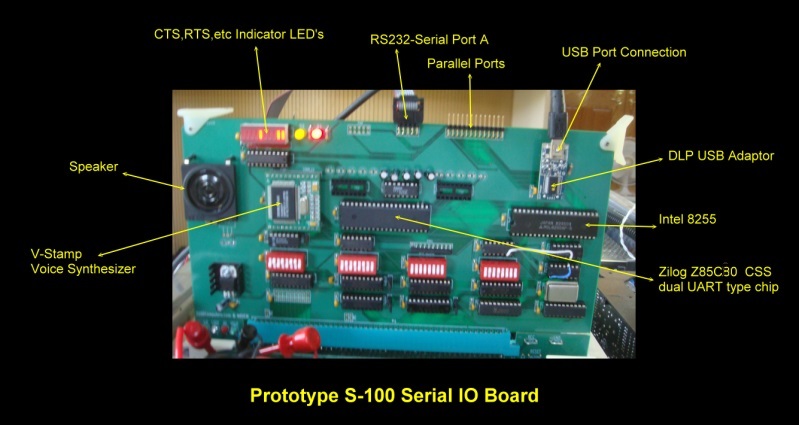

Serial IO Board Version V4.2

This board has been around 2010. It has shown itself to

be very popular and reliable. It is overdue a few tweaks and

improvements however.

Damian Wildie in Australia has

utilized the board as a console serial interface for use with Cromemco's

Cromix using our 68030 CPU

board.

Cromix is a popular OS for Cromemco computers with its

Unix like structure.

Please see:-

Introduction to Cromix-Plus Users Manual.pdf

Cromix-Plus Programmers Reference Manual.pdf

for more

information.

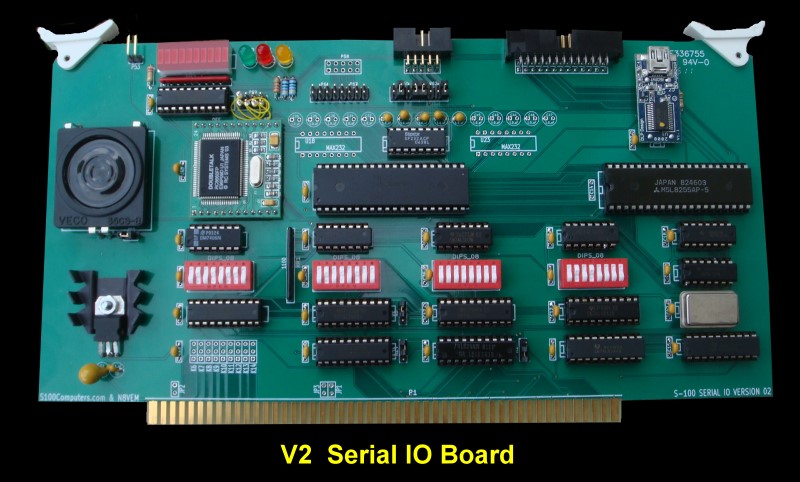

The new V4.2 board is identical to the V3.1 board with the following

additions:-

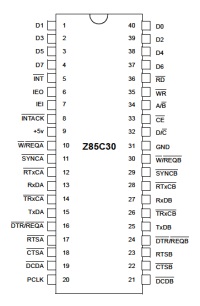

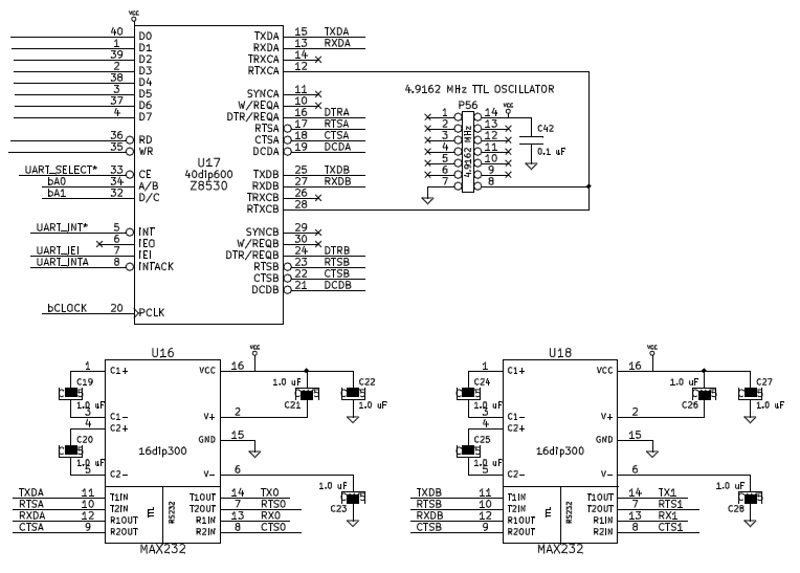

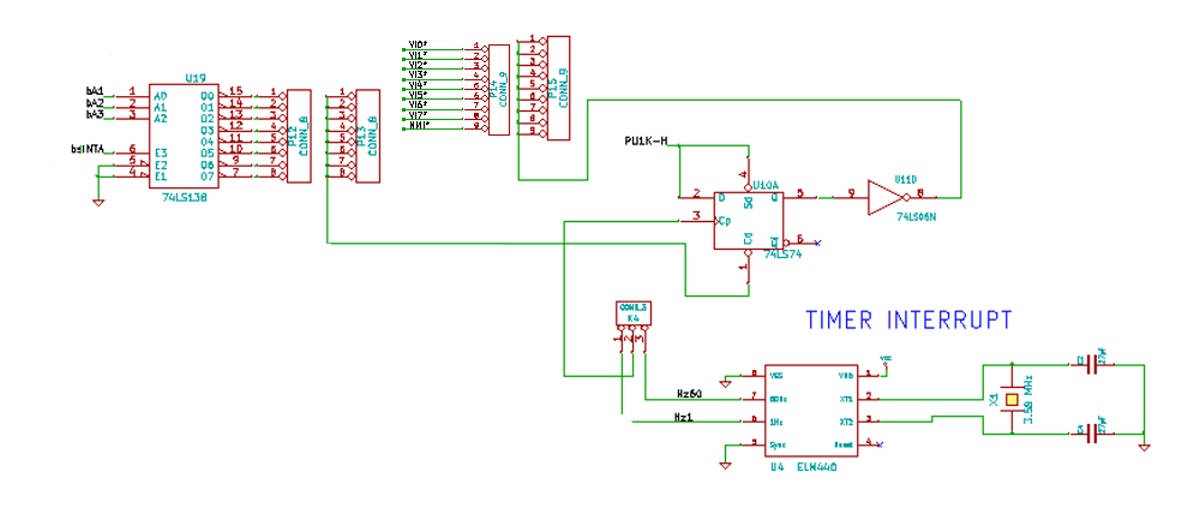

Z8530 Interrupts

The TBE & RDA interrupts generated by the Z8530 (U17) for both serial

ports are needed to run Cromix. Configuring the Z8530 to trigger

INT

is fairly straight forward, however,

the Z8530 requires its

INTACK

pin to be pulled low to deassert the

INT

signal. There is no circuitry on the board V3.1 board to do this.

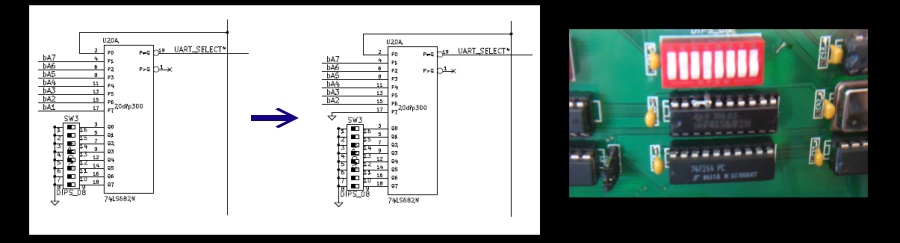

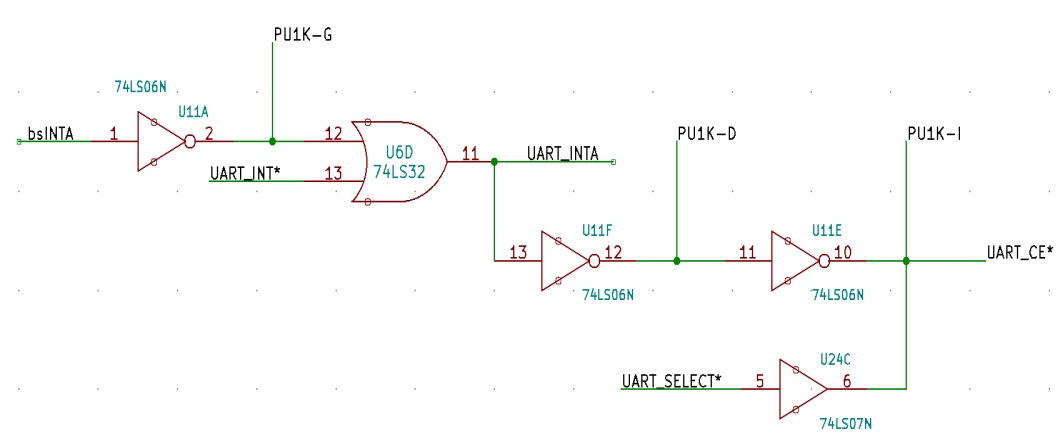

Damian implemented the following circuit using the spare gates and pull-ups

on the V3.1 board to do this.

bsINTA

is the S100

sINTA

via the spare buffer in U14. We have now incorporated a

proper

INTACK

signal in the V4.2 board.

An Onboard Timer Signal

The

Cromemco DPU &

XPU

CPU boards do not have a RTC chip. They rely on two timer

interrupts from the TMS5501 on the

16FDC

and 64FDC Boards.

One interrupt at 16 ms intervals for the system clock and another at 524288

uS for the real time clock. These values are not critical, A single

~100ms SMB board interrupt

for the system clock and from this calculating the real time increment

can be done -- but is not real accurate and subject to drift.

At boot time, the user is required to enter the current data and time to

initialize the real time clock. A stable 60Hz interrupt would work much

better. If this interrupt was to be combined with the Z8530's

interrupt, it would be necessary to be able to quickly identify the source.

Alternatively a different interrupt level could be used. It is

possible to utilize the timer on our

MSDOS Support Board but

this adds another board to the minimum system to run Cromix. A better

solution is to add an

EML440 timer

chip to the serial board. We have had good success with this chip on our

PDP11 CPU board.

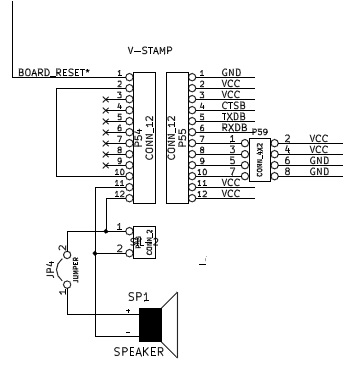

With at 60Hz with a 50% duty cycle from the ELM440, the Z8530 interrupts are

frequently being missed. By changing the square wave to a 10uS pulse

however it works reliably. Damian used a level 3 for the timer and 5 for

the Z8530. With this arrangement the interrupt circuitry on the 68030 board

appears to be working correctly, the 74LS148 correctly prioritized the level

5 interrupt whilst the level 3 line is held low. The timer interrupt

handler does not explicitly mask higher level interrupts, unless there is

something in Cromix that does. To work around this, he added a

resettable D type flip-flop to the output of the ELM440 that is reset by the

S100 bus sINTA signal. Here is the

relevant part of the schematic:-

DB9 Connectors

The original Serial Board has a fair amount of unused board space.

It utilized two 10 pin headers to connect ribbon cables to the back of the

S100 Box for serial connections. For convenience we now add two female

DB9 sockets to the top of the board for simple quick connections. In

most cases this of course will not allow the cover to be placed on the top

of the S100 box however. Something in reality rarely done!

Pololu 5V Voltage Regulators

Besides the footprint for the linear 5V regulator and space for a heat sink

the V4.2 board now has pads to utilize the Pololu

D24V22F5 or

D24V25F5 5V regulators as well.

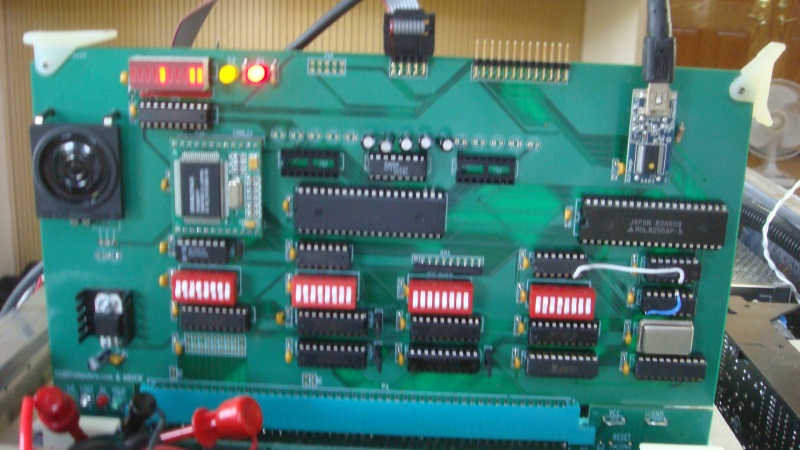

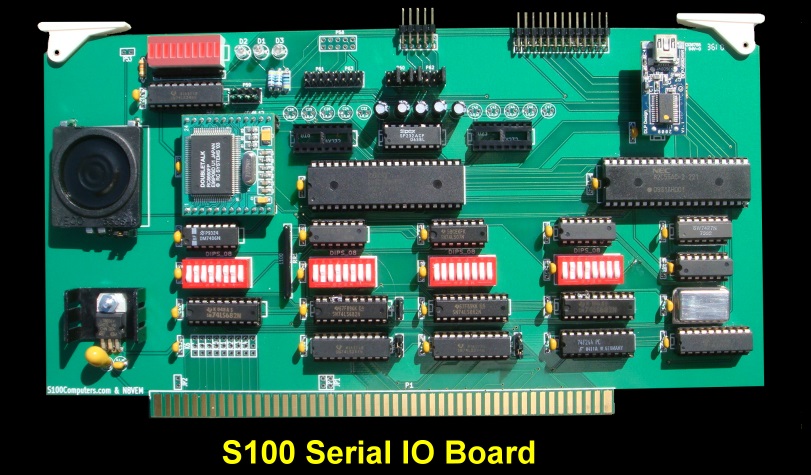

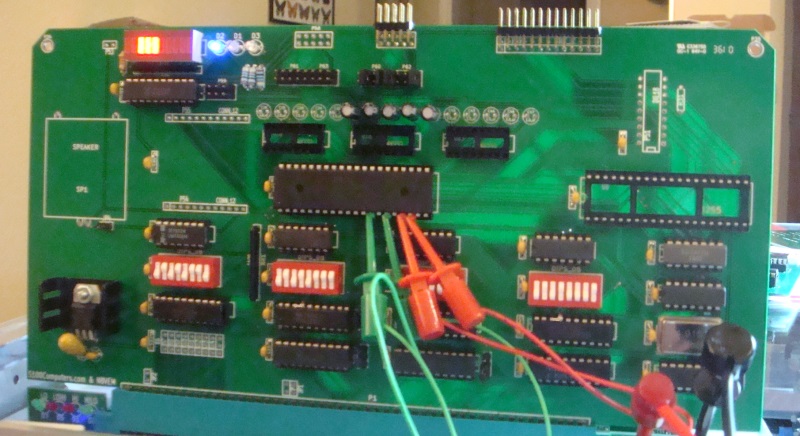

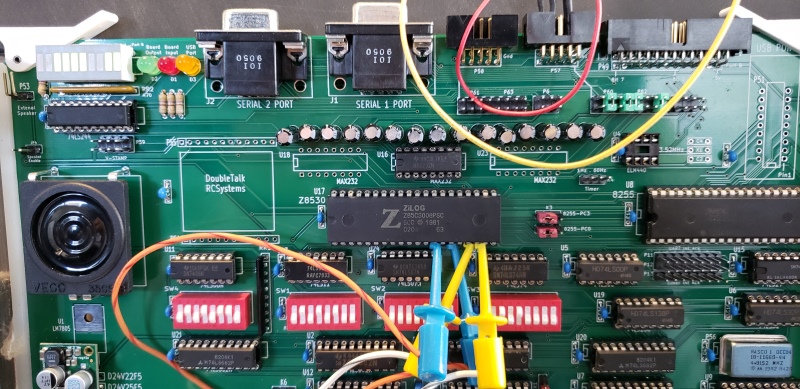

Here is a picture of this Serial IO board V4.2 version.

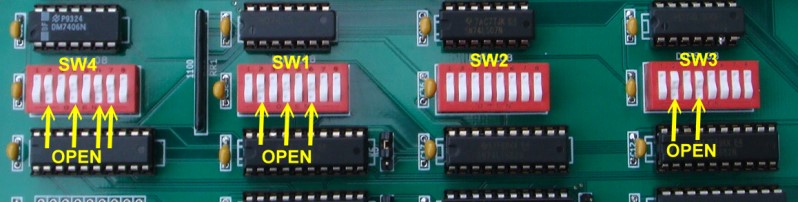

The build process and jumper connections for this board are almost identical

to that of the V3.1 version. The configuration switch settings are

identical.

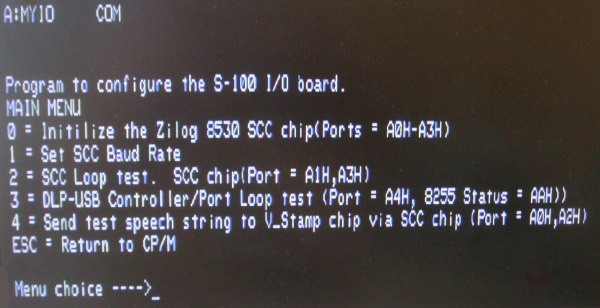

During the build be sure you get the serial "loop back" test

working before going further. If you pass that test much of the board is

working. Use the MYIO.Z80 program to test

the board.

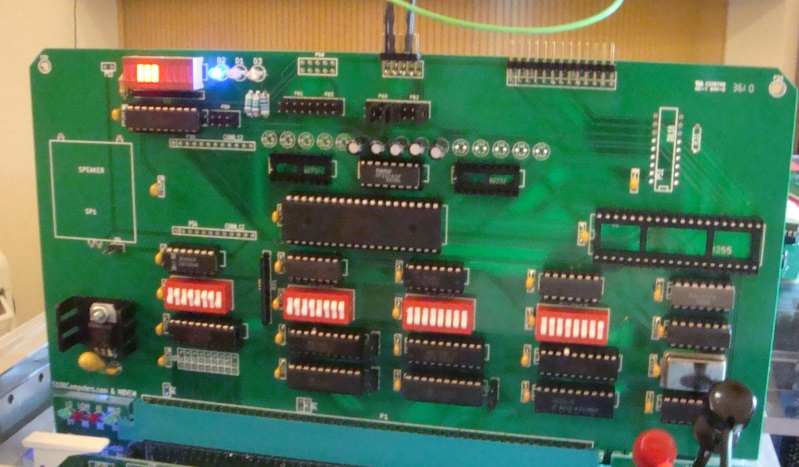

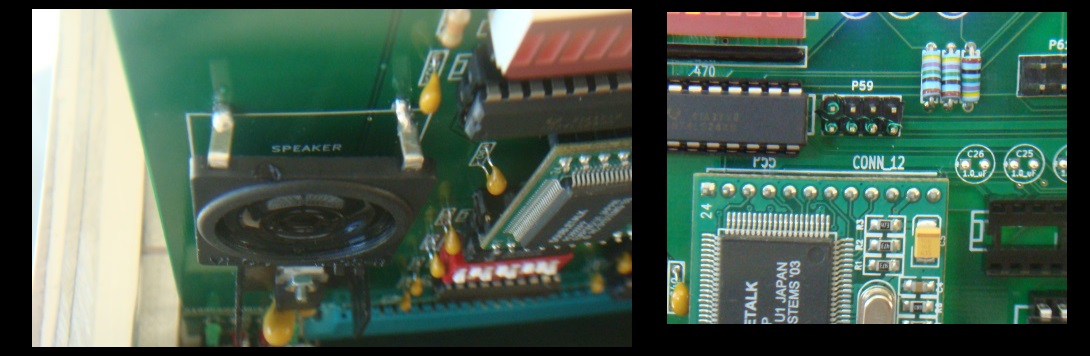

Here again is a close-up picture:-

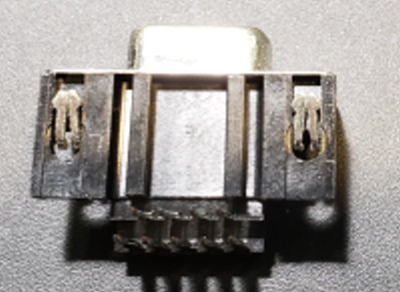

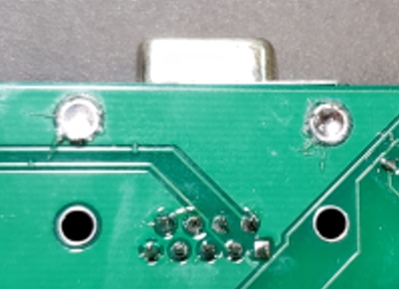

Please note for some DB9 Sockets the large ground/case pins do not line up

with the large board holes. Just bend them flat and later fill the two

board holes with solder. This attaches them to the board.

Here is a picture:-

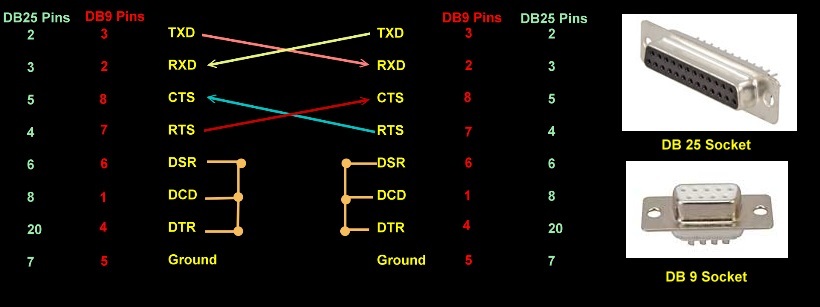

Setting up jumpers/wires for an RS232 connection makes one really appreciate

the USB socket. The board has jumpers such that almost any

configuration can be configured. That's the good news. The bad news is

that are many possible connections to chose from. You first need to

decide if your serial connection is a "modem" or a "Computer" to another

terminal/computer. This affects how the RS232 pins 2 and 3 are

configured.

I use this board a lot to download and upload programs to/from my PC.

For this I use a USB port on the PC and a Serial -> USB port adaptor

connection on this board that connects in to the boards Serial port #1.

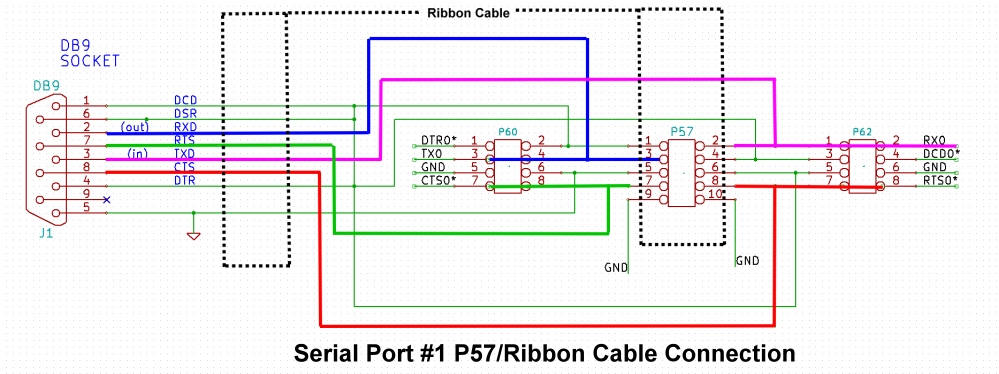

For the onboard P57 socket connected to a ribbon cable that is connected to

a DB9 female socket at the back of the S100 Box here is the jumper

arrangement.

The ribbon cable P57 pins connect to the DB9 pins as follows.

Cable

1->DB9 1, Cable 2->DB9 3, Cable 3->DB9 2,

Cable 4->DB9 4, Cable 5->DB9 5

Cable 6->DB9 4+6+1, cable 7->DB9 7, Cable 8->DB9 8, Cable 9->DB9 9,

Cable 10->DB9 NC.

P60 3->4, 7->8. and for P62 1->2, 7->8

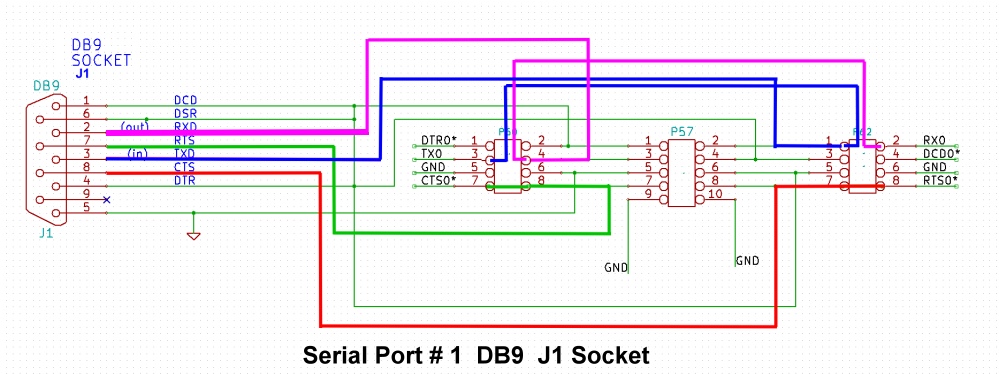

If you use the onboard DB9 J1 socket, here is the setup:-

P60 pin 3 to P62 pin 1, and P62 pin 1 to P60 pin 4.

Also P60 7->8 and P62 7->8.

Jumper P5 1->2, 3->4, 5->6.

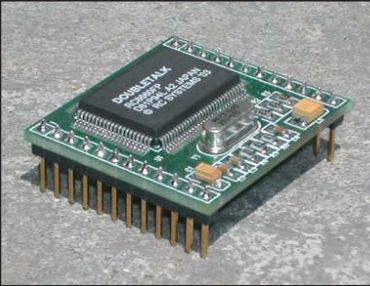

The

ELM440 (U4 )can be ordered directly from ELM

here (in Canada). Its not

cheap ($8 each), but it seems very reliable/accurate. Here is the

ELM440 datasheet.

It

should provied a 1 or 60Hz signal on K4 and can be used as described above

or as a rough RTC.

Bugs

Henry Broekhuyse and Damian Wildie pointed out there

are errors affecting serial port 1 connector J1 and

J2 connector for serial port 2.

The schematic shows DB9B_RxD connecting J2-2 to P63-1 and P58-2. On the

board, DB9B_RxD is actually connected to P63-3 and P58-4

The schematic shows DB9B_DTR connecting J2-4 to P61-2 and P58-1. On the

board, DB9B_DTR is actually connected to P61-6 and P58-5

The schematic shows DB9A_DTR connecting J1-4 to P60-2 and P57-1. On the

board, DB9A_DTR is actually connected to P60-6 and P57-5