Introduction to the 8MB Mezzanine RAM mini-Boards

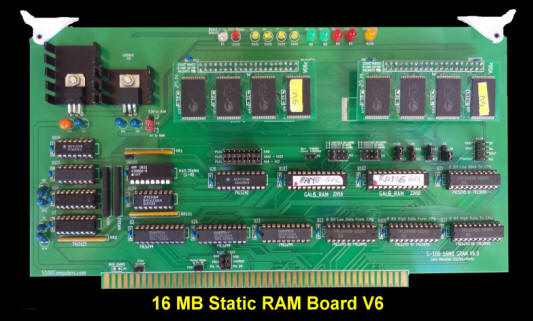

Our 16MG Static RAM

board turned out to be a great success. The board was fast and could handle 8 and 16 bit data paths 100% reliably with all the CPU's I could throw at it. It reliably runs with our

Z80,

6502,

8088,

8086,

80286,

68000

and 80386

CPU boards. I have not found a vintage S100 CPU board that would not work with it.

Here is a picture of the board -- as well as a 32MB RAM board (see below).

The actual static RAM chips used with these boards are the Cypress 2MB X 8 (CY62167's). They come in two formats, the

CY62167E

which run with a Vcc voltage of 5 Volts and a

CY6216DV30 which runs with a Vcc of 3.5 Volts. Both are available from a number of venders -- though there is a wide price range. The 5 Volt units

(which I prefer -- in my hands are more heat resistant) are a little more expensive. I get mine from

Arrow Electronics (CY62167ELL-45ZXI). They are not cheap ~$10 each. So it will cost you about $80

in RAM chips to completely fill your S100 bus system with this board. Not bad

when you remember that once upon a time you paid that for 1K of RAM!

The boards utilized two "mezzanine mini-boards" that hold the actual

SMD RAM chips. SMD chips had to be used because nobody makes a 2M X 8 static RAM chips in a DIP chip format. In line with current trends, all new high capacity static RAM chips are in a surface mount format.

These same mezzanine RAM mini-boards are used with out

OTT

32MB RAM boards for used with our

80386 (and 80486)

CPU boards.

The only problem is soldering on the SMD RAM chips to the mezzanine boards.

There are four RAM chips per boards. I have done a number of these

boards and have always found it a challenge, sometimes ending up with a dead RAM

chip -- due to either a bad solder joint or an over-heated RAM chip. I

concluded that the main problem was the solder pads on the "V06c" mezzanine

boards were too small. What is needed are longer horizontal pads which can

be layered with solder and then one only has to touch each RAM chip pin briefly

to have it fuse with the solder below it.

A new "V06d" mezzanine RAM mini-board is presented here along with more details

as to how to solder the RAM chips to these boards and check them out.

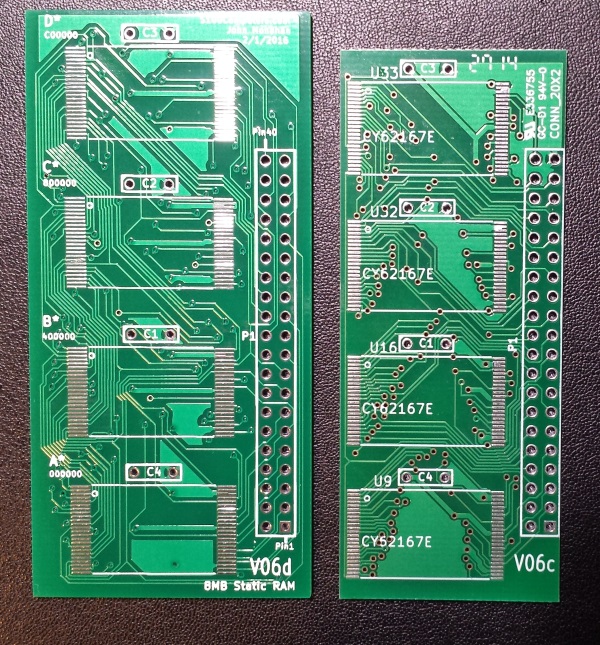

First here is a picture of the old and new mezzanine boards.

You can immediately see that the V06d boards are slightly larger, but more

importantly the RAM solder pads are wider.

SOLDERING SURFACE MOUNT RAM CHIPS

Everybody seems to have their own way to solder SMD chips by hand. There

are many excellent videos on the web outlying various procedures.

I found this

U-Tube

video

helpful.

Step by Step.....

Use a very fine tip 10-15W soldering iron.

The tip must be small enough not to bridge more than two RAM chip pins.

With a small brush cover the board solder pads with solder paste (I use,

"DeoxIT Rosin Soldering Flux").

Here is a before and after flux application.

Then "slop" solder on all the pads evenly. Run the iron down the pads. The

flux will prevent pad solder bridges. When done each pad should have a mound of

solder on it but not so much as to bridge across to the next pad. Then remove

the excess flux with flux remover spray. ( I use "Fux Wash" by DeoxIT).

Blow air over the board to completely dry it. Do not touch the pads with

your fingers. Here is a picture of the prepped board.

Its not very clear in the picture but each pad has a layer of solder on it

evenly spread.

Next add a little solder flux again. Very little is required -- just a thin

film.

Carefully align pin one on the circuit board pad so the visible pad is

equal on both sides of the chip. (i.e. the chip is exactly centered).

Press down on the chip and touch the solder pad for pin 1 with the soldering iron. If it is clean no

actual solder is required.

There is sufficient solder on the board and chip to make a connection.

Next go to pin 25. Carefully align the chip so all pins are exactly over the

circuit board pads and solder exactly as for pin one.

Its critical to have careful alignment of the pins with the pads. Before

soldering check the opposite diagonal chip pins are not off.

I have found the easiest way to aligned pin 25 is to place a blade at the side of

the chip and twist the blade slightly. This very slightly moves the chip.

Next with your very fine tip soldering iron touch the solder on each pad and

scoop it towards the RAM chip pin all the time pressing down on the RAM chip

with your finger. Do not over solder. The mere melting of the solder is

actually sufficient for a good pin contact. If you feel the RAM chip getting

hot stop immediately and let it cool. I have found these chips do not tolerate

overheating well. I usually stop after 5 pins for a few seconds to let things

cool. I cannot stress enough that the slightest melting of the solder on the pad

is all that is required.

When done remove the excess flux with flux remover spray. Blow air over the

board to completely dry it. Here is a picture of a RAM chip soldered as

described above.

It should not be necessary, but just to be safe, with a magnifying glass carefully examine each pin for cross bridges.

If found, remove with solder wick.

I have recently started to use a headgear unit that contains a light and

binocular magnifying glass. Jewelers use them, there are many on the web.

Looks geeky but it really helps with the above.

DEBUGGING

These boards contain a lot of RAM. If you are using them for a Z80 (64K

RAM) chances are you will not have a "bad patch". You just have to have

the lowest region of the RAM working. In order to test/debug a board it is

useful to understand how the RAM on this boards is arranged.

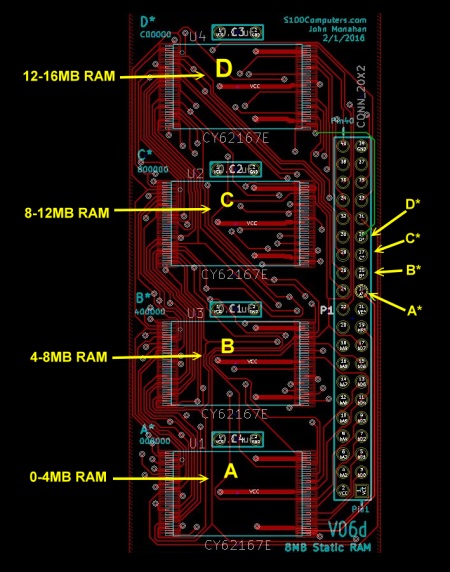

For 16MB RAM board (all versions), one mezzanine board addresses even bytes

(connector P104), in the S100 bus address space, the other odd bytes

(connector P103). This means that this board would never

work correctly with only one mezzanine board.

Next on each mezzanine board there are 4 chips. The individual chips are

addressed (using address lines A22 & A23) as shown here:-

What this means is that the most critical chip is the bottom chip beside pin 1

of the boards connector. To get started you should solder one RAM

chip in this position on two mezzanine boards. Insert them in your system

and see if you can boot up your Z80 monitor. If not, check for solder

bridges and/or with a fine blade/needle see if any of the RAM chip pins move on

the board. Re-solder and retry. Do not go forward until the problem

is solved. If need be, remove the chip with a heat gun and try another.

Sometimes it helps to place a little solder flux on the RAM pins before

resoldering. Be sure to remove it with flux remover however before powering up

your system.

Next see if you can boot a banked version CPM3 (which uses RAM above 64K).

Next see if you can boot the 8086 monitor and MSDOS. If this works you

probably have a good lower 1MB of RAM.

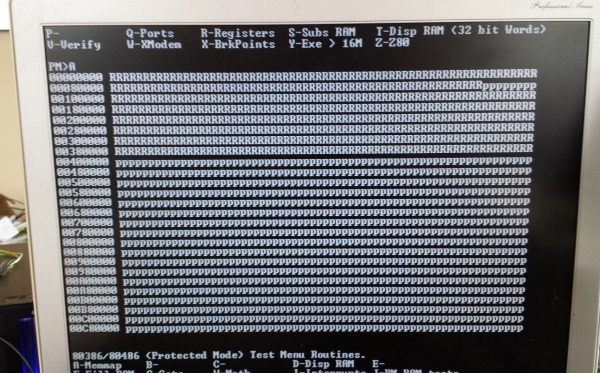

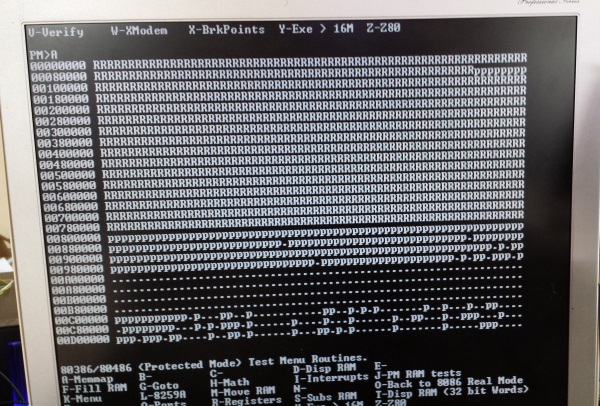

The real test comes with the extensive tests in the 80386 (protected mode)

monitor.

First do a memory map ("A" command). It should appear like this:-

Then use the protect mode "J" command, option 7, to check RAM from 100000H to

3FFFFFH.

If all is well insert the second RAM chip (B) on the pair or

mezzanine boards. Repeat the above tests. The memory map should now

look like this:-

Don't worry about RAM above 7FFFFH. Noise on the bus will give various

configurations.

Then use the protect mode "J" command, option 7, to check RAM from 100000H to

7FFFFFH. If all is well insert the third and fourth RAM chips (C & D) on the

pair or mezzanine boards. Repeat the above tests. Then do a complete

16MB 80386 RAM test using the "J" command, menu #4. Here is a

picture of a checked out board result:-

For the

32MB

RAM OTT board (all versions), the addressing is different. The 4

vertical mezzanine boards address bytes 0, 1, 2 and the 3 respectively. So

to test RAM you will need 4 mezzanine boards. Again one chip per board is

fine to start with. Sometimes its easier to check the mezzanine boards in

a 16MB board first before popping them into a 32MB board.

Bugs and Notes

I have not found any bugs in

this board so far, however they do not fit well in the very first (V1) 16MB RAM

board. They are a little too wide and overlap each other in the board. The work

fine, just not a neat arrangement. They fit fine in the V5 & V6 boards.

Also if you are on a tight budget, you need only add

the first RAM chip to both mezzanine boards yielding an S100 bus system with 4MB

of RAM.

A Production V06d Mezzanine Board

Realizing that a number of people might want to utilize a

board like this together with a group of

people on the

Google

Groups S100Computers Forum, "group purchases" are made from time to time.

Please see

here for more

information.

Please note if you have V06c mezzanine mini-boards they are perfectly fine. The

circuit is identical to that on the V06d boards. Only the RAM pin pads

size are different.

The soldering approach is exactly the same.

MOST

CURRENT 8 MB MEZZ BOARD SCHEMATIC

(V06d 3/21/2016)

MOST

CURRENT 8 MB MEZZ BOARD KiCAD Files

(V06d 3/21/2016)

V6d Mezzanine KiCAD files (V06d,

Final 4/1/2017)

Other pages describing my S-100 hardware and software.

Please click

here to continue...

This page was last modified

on 11/30/2017