We will write software for all these steps. Normally

I have seen the process written from the bottom up. I think it is in fact easier

to understand if we go from the top down.

SOFTWARE DOWNLOADS

All the software mentioned on this page can be downloaded from the links at the

bottom of this page.

They contain my most recent updates and may not

correspond exactly with the text here.

Also in this particular case, I am

including the Altair CPM

Simulator in the same folder so people can run the system

immediately on

windows.

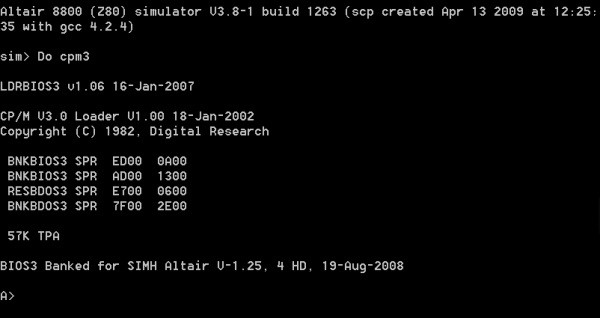

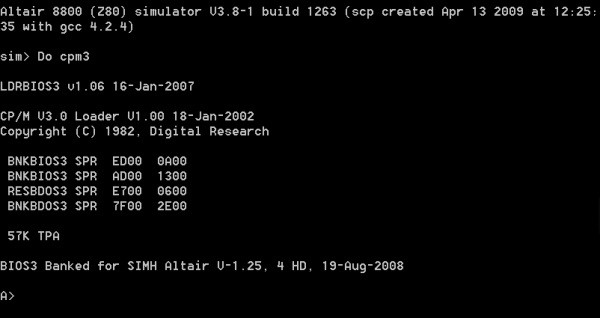

Double click on altair80.exe to launch the program. This will create

a SIMH specific DOS box window.

At the "A>" prompt within that window type:-

do cpm3

After the carriage return you will see a completely self contained and

functional CPM3 system. The box will look like this:-

The simulator behaves like a ~50MHz Z80 driven system. For example

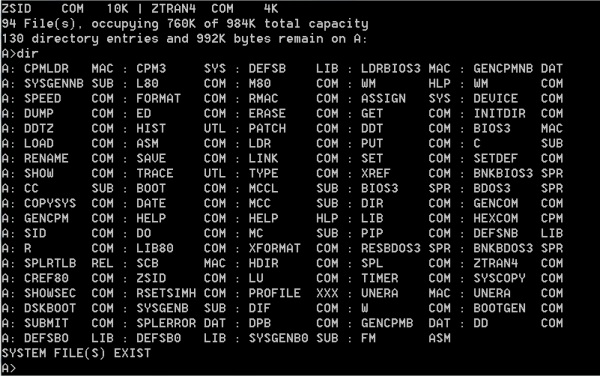

to see the user 0 directory type:-

DIR

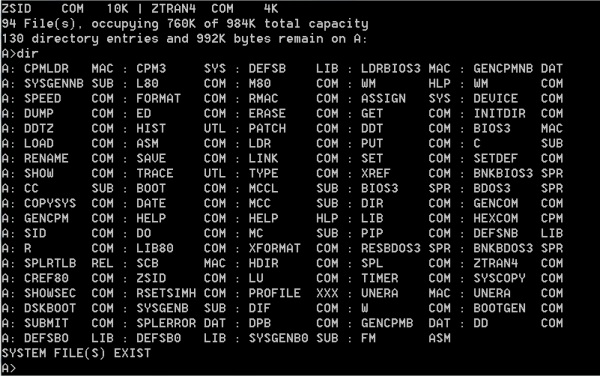

You will see the normal CPM3 directory listing, something like this:-

You can read up on CPM3 to run many of these programs. Other "well known"

programs have been added as well. They are marked as CPM3 "System files" so they

can be run from any drive and user group.

For our needs here however, we will take advantage of the fact that the simulator has

an large memory disk "I:" drive that we will normally use as our work

disk. So typing "I:" CR will bring you to that

drive.

You should see:

I:>

Within that drive will be already the relevant files to run the

CPM3 files discussed below. This makes it a one click process for

beginners, however unfortunately the combined set of CPM files and CPM3

simulator is quite large (~4GB) because it contains many other CPM programs not

used here. For further CPM3 software downloads on other pages I will just

supply the source code and you can splice in the simulator yourself as describe

here.

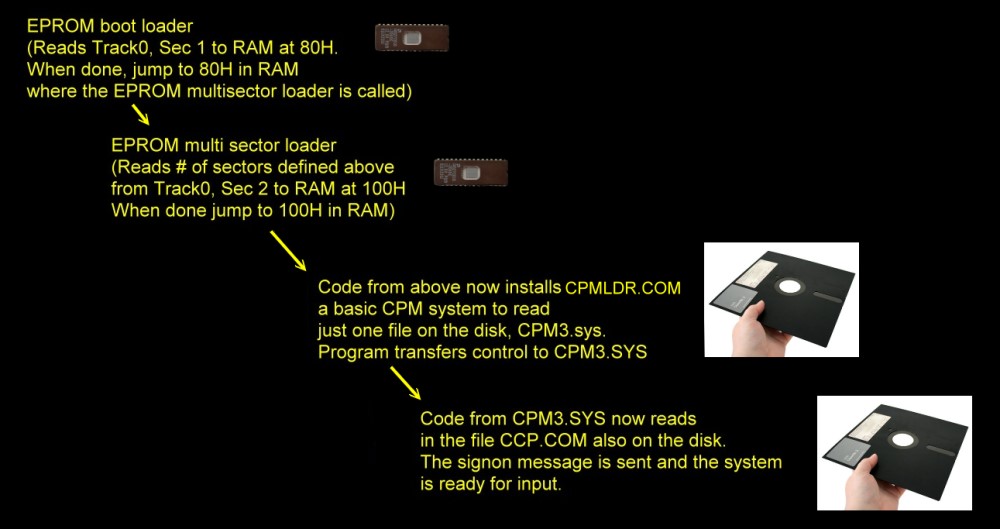

OK lets get started. Starting form the top item in the above diagram:-

THE EPROM BOOT SECTOR LOADER.

This small piece of 8080/Z80 code resides in your boot monitor. Because

the amount of space in a ROM monitor is small (typically 4K) this code has to

be simple and compact. Also because this same "Boot Loader" may be used to read

in different operating systems (CPM 1.4, CPM2.2, CPM 3, DOS etc) or

different disk sizes/densities, we need a

flexible way of reading in a different number of sectors from a disk. We do this

in a two step process. We read in (always) the first sector to 80H in RAM, jump

to that location which will have specific code on that disk for

that operating system to determine how many further disk

sectors are to be read. These sectors are then read in by further code in the

ROM monitor placing them at (for CPM), 100H in RAM. The ROM monitor

code then removes itself from the process and transfers all control to CPM

starting at 100H in RAM.

The code at 100H is RAM is really a stripped down very compact CPM operating

system (called CPMLDR.COM) that's only function in life is to read is a

single CPM file on the disk named CPM3.SYS. It has to be a "proper" CPM

operating system however because the CPM3.SYS file is a "normal" CPM file and can

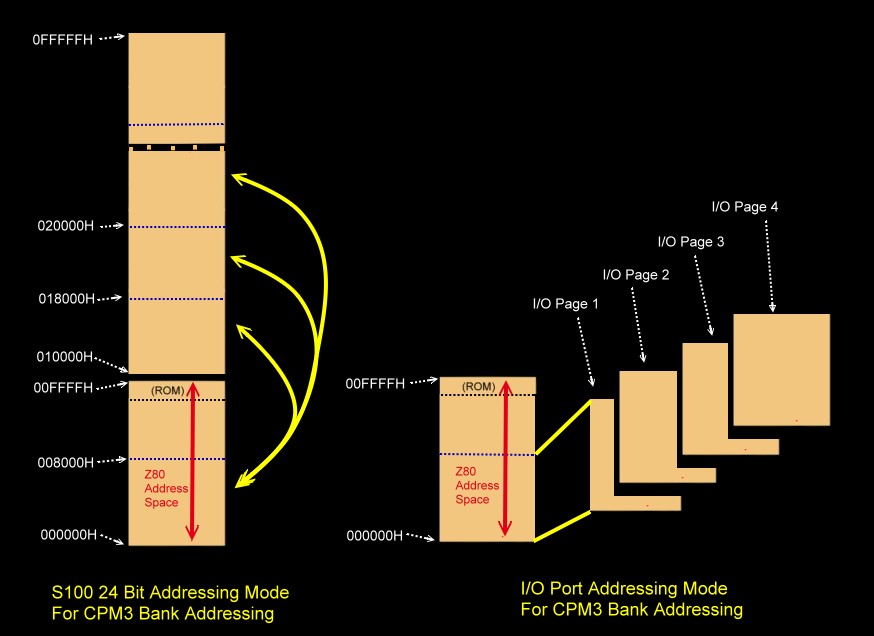

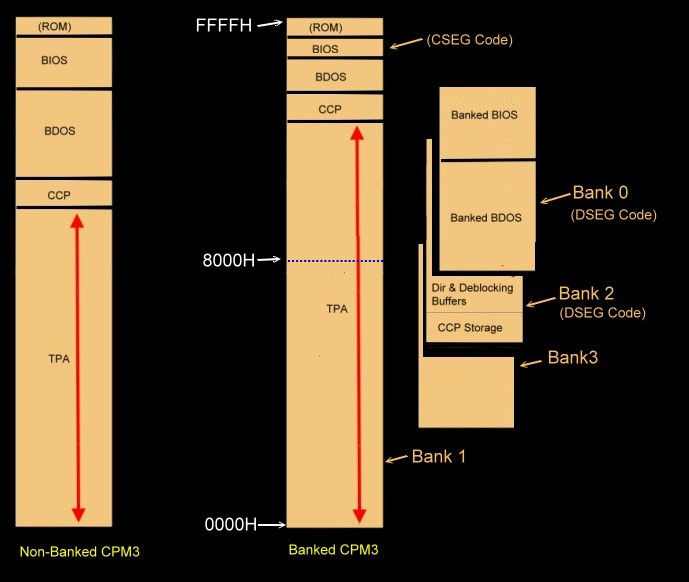

exist anywhere on the disk. In a Non-Banked system this CPM3.SYS

code is placed in the top of RAM. In a Banked system much of it is placed in

another RAM bank - thus freeing up much of the TPA. More on that later.

We are almost home. The last step in the process is the CPM3.SYS code

itself reads in a further CPM3 file called CCP.COM. This Console Command

Processor file has the code that links the operating system with the

outside world (console, printer etc). When this is done the CPM3.SYS code

transfers control to the CCP.COM code and the A:> appears.

This my seem a convoluted way of doing things -- and to some extent it is,

however what is really nice is that once you have the original CPMLDR working

you can easily and quickly make changes to the operating system by placing a new

CPM3.SYS file on the disk. If you change the name (CPM always looks for

exactly "CPM3.SYS") you can have different hardware arrangements stored on the

same disk.

Note in the earlier versions of CPM (1.4, 2.2 etc) the process was much

simpler. The first boot sector code caused the ROM monitor to load the

remaining sectors of CPM code in high memory and just jump to that location.

Any time a change was made to the BIOS however, the whole system had to be

rebuilt.

Now let us look at an example of the EPROM boot loader code. My complete

"MASTER.Z80" EEPROM code can be see

here. The relevant

BIOS loader code begins at ZFDC_BOOT:

This is the monitor I use with the S100Computers

Z80 CPU

board. It utilizes the simple command driven interface to read disk

sectors into RAM utilizing the

ZFDC board.

;---------------------- ZFDC FDC EEPROM BOOT LOADER -----------------------------------

ZFDC_BOOT: ;Cold Boot with ZFDC FDC Board

OUT RESET_ZFDC_PORT,A ;Do a ZFDC board hardware reset. Does not matter what is in [A]

LD A,STATUS_DELAY ;~0.5 second at 10 MHz

LD BC,0 ;Delay to allow board to setup hardware

WAIT_D: DEC B

JR NZ,WAIT_D ;Delay for ~0.5 seconds

DEC B ;Reset B to 0FFH

DEC C

JR NZ,WAIT_D

DEC A

JR NZ,WAIT_D

IN A,S100_DATA_B ;Check the board is there

CP A,CMD_HANDSHAKE ;Make sure we get HANDSHAKE byte back

JP NZ,ERR_NR ;If error, just abort

LD A,CMD_HANDSHAKE ;Send another byte just to be sure.

OUT S100_DATA_B,A ;This clears up ints on ZFDC board

CALL WAIT_FOR_ACK ;Wait to make sure all is well.

OR A,A

JP NZ,ERR_NR ;If error, just abort

LD C,CMD_SET_FORMAT ;Send Set Disk Format to 8" SSSD DISK

CALL S100OUT

LD C,0 ;Floppy Drive 0, (ZFDC Board expects a 0H, 1H, 2H or 3H)

CALL S100OUT

LD C,STD8IBM ;ZFDC Board expects a Disk Format Table Number (0,1,2...13H)

CALL S100OUT

CALL WAIT_FOR_ACK ;Return Z (and NO_ERRORS_FLAG in [A]), or NZ with error # in [A]

JP NZ,ERR_NR ;If error, just abort

LD C,CMD_SET_DRIVE ;Send a "Set Drive CMD" to ZFDC board

CALL S100OUT

LD C,0 ;Floppy Drive #, (ZFDC Board expects a 0H, 1H, 2H or 3H)

CALL S100OUT

CALL WAIT_FOR_ACK ;Return Z (and NO_ERRORS_FLAG in [A]), or NZ with error # in [A]

JP NZ,ERR_NR ;If error, just abort

;Drive selected and ready to read sectors. Note this code

;is written to be compatible with the boot loader for the

;Versafloppy-II disk controller as well.

LD A,STDSDT ;SETUP FOR SD

LD (@COUNT),A ;STORE AS 26 SECTORS/TRACK

XOR A ;Setup Boot Sector read track

LD (@TRK),A

INC A

LD (@SCTR),A

LD HL,COLD ;Will load the boot sector to 80H in RAM

LD (@TADDR),HL

CALL ZFDC_READ_SECTOR

JP NZ,ERR_LD

LD HL,COLD ;Check the load went OK.

LD A,(HL)

CP 31H ;EXPECT TO HAVE 31H @80H IE. LD SP,80H

JP Z,COLD ;AS THE FIRST INSTRUCTION. IF OK JP 80H

JP ERR_LD1 ;Boot Sector Data incorrect

ZFDC_READ_SECTOR: ;CORE code to read a sector with ZFDC board

LD C,CMD_SET_TRACK ;Set Track

CALL S100OUT

LD A,(@TRK)

LD C,A

CALL S100OUT ;Send Selected track HEX number

CALL WAIT_FOR_ACK ;Return Z (and NO_ERRORS_FLAG in [A]), or NZ with error # in [A]

JP NZ,ERR_NR ;If error, just abort

LD C,CMD_SET_SECTOR ;Set Sector # to side A (or for DS disks also side B)

CALL S100OUT

LD A,(@SCTR)

LD C,A

CALL S100OUT ;Send Selected sector HEX number

CALL WAIT_FOR_ACK ;Return Z (and NO_ERRORS_FLAG in [A]), or NZ with error # in [A]

JP NZ,ERR_NR ;If error, just abort

LD C,CMD_SEEK_TRACK ;Later can let board do this

CALL S100OUT

CALL WAIT_FOR_ACK ;Return Z (and NO_ERRORS_FLAG in [A]), or NZ with error # in [A]

JP NZ,ERR_NR ;If error, just abort

LD C,CMD_READ_SECTOR ;Routine assumes required Drive Table,Drive,Side,Track, and sector are already sent to board

CALL S100OUT ;(Note [HL]-> Sector DMA address)

CALL WAIT_FOR_ACK ;Wait for NO_ERRORS_FLAG to come back

JP NZ,ERR_NR ;If error, just abort

LD HL,(@TADDR) ;Set DMA address

LD DE,(@SEC_SIZE) ;For CPM this will be 128 Byte sector(s)

RD_SEC:CALL S100IN ;Note potential to lockup here & below (but unlightly)

LD (HL),A

INC HL

DEC DE

LD A,E

OR A,D

JR NZ,RD_SEC

CALL WAIT_FOR_ACK ;Return Z (and NO_ERRORS_FLAG in [A]), or NZ with error # in [A]

RET

S100OUT:

IN A,S100_STATUS_B ;Send data to ZFDC output (arrive with character to be sent in C)

BIT DIRECTION_BIT,A ;Is ZFDC in output mode, if not wait

JR NZ,S100OUT

BIT DATA_OUT_RDY,A ;Has previous (if any) character been read.

JR Z,S100OUT ;Z if not yet ready

LD A,C

OUT S100_DATA_B,A

RET

S100STAT:

IN A,S100_STATUS_B ;Check if ZFDC has any data for S-100 system

BIT DATA_IN_RDY,A ;Anything there ?

RET Z ;Return 0 if nothing

XOR A,A

DEC A ;Return NZ, & 0FFH in A if something there

RET

S100IN:

IN A,S100_STATUS_B ;Check if ZFDC has any data for S-100 system

BIT DIRECTION_BIT,A ;Is ZFDC in input mode, if not wait

JR Z,S100IN ;If low then ZFDC board is still in input mode, wait

BIT DATA_IN_RDY,A

JR Z,S100IN

IN A,S100_DATA_A ;return with character in A

RET

WAIT_FOR_ACK: ;Delay to wait for ZFDC to return data. There is a timeout of about 2 sec.

PUSH BC ;This can be increased if you are displaying debugging info on the ZFDC

PUSH DE ;HEX LED display.

LD BC,0

LD E,STATUS_DELAY ;Timeout, (about 2 seconds)

WAIT_1: IN A,S100_STATUS_B ;Check if ZFDC has any data for S-100 system

BIT DIRECTION_BIT,A ;Is ZFDC in input mode

JR Z,WAIT_2 ;if low then ZFDC is still in input mode

CALL S100STAT ;Wait until ZFDC Board sends something

JR Z,WAIT_2

CALL S100IN ;Get returned Error # (Note this releases the SEND_DATA routine on the ZFDC board)

CP A,NO_ERRORS_FLAG ;Was SEND_OK/NO_ERRORS_FLAG sent back from ZFDC Board

POP DE ;Balance up stack

POP BC

RET ;Return NZ if problem, Z if no problem

WAIT_2: DEC B

JR NZ,WAIT_1 ;Try for ~2 seconds

DEC B ;Reset B to 0FFH

DEC C

JR NZ,WAIT_1

DEC B ;Reset B to 0FFH

DEC C

DEC E

JR NZ,WAIT_1

XOR A,A

DEC A

POP DE ;Balance up stack

POP BC

RET ;Return NZ flag set if timeout AND 0FFH in [A]

As I explained above, we have just read in one sector to RAM at 80H. The

next piece of code is the EEPROM code to read in the next (in our case) 51

sectors from Track 0 and 1 on the 8" floppy disk. The simple EEPROM code

to do this is shown here:-

; LOAD A NUMBER OF SECTORS ;Note this loader will be particularly slow since the sector

;reads are not skewed. (Actually one rotation/sector)!

ZFDC_LOADER: ;Loader with ZFDC FDC Board

CALL ZFDC_READ_SECTOR

JP NZ,ERR_LD

LD C,'.' ;Show progress

CALL CO

CALL INCP ;Increment sector, track adjust NREC

JR NZ,ZFDC_LOADER

RET

; INC SECTOR AND TRACK

INCP: LD HL,(@TADDR)

LD DE,(@SEC_SIZE) ;128 or 512 byte sectors

INCP2: ADD HL,DE

LD (@TADDR),HL

LD HL,@NREC

DEC (HL)

RET Z ;Return when we have done all sectors (~51)

LD HL,@SCTR

INC (HL)

LD A,(@COUNT) ;IS ONE TRACK DONE YET (Sec/track+1)

INC A

CP (HL)

RET NZ ;IF FULL Z, THEN GO TO NEXT TRACK

LD (HL),1 ;SET SECTOR COUNT BACK TO 1

INC HL ;ASSUMES @TRK=SECTOR+1 IE 44H

INC (HL)

OR A ;MAKE SURE TO RETURN NZ

RET

The key variable is @NREC. This is the number the

first sector code placed in RAM (at 45H) to tell this module how many further

sectors to read in. Note how the ZFDC_LOADER routine just does a simple

return when finished. Its again is up to the code from the first sector to then

jump to 100H in RAM.

THE EPROM CPMLDR LOADER.

Next we will write the CPM Loader program

CPMLDR.COM. This is actually the hardest part of the software to write.

We are is essence writing a primitive CPM3 BIOS. The good news is we don't worry

about memory banking, and only have to take care of two major BIOS functions,

reading sectors from (only) the boot disk and writing to the console.

You don't even need console input -- though it is useful for debugging.

In CPM3 each disk has its own Disk Parameter

Block table. Unfortunately

these tables (DPB's) are fairly complex and rather

than repeat everything here, you should read the Digital Research

CPM3

System Guide

mentioned above. They contain byte and word values to define areas in RAM

for sector skew translation, directory buffers and hash tables etc.

We will not worry about any of this now because Digital Research provides a

series of Assembler macros that builds these tables automatically for you.

For our 8" disk the DPB macro is:-

Floppy$DPB: DPB

128,26,77,1024,64,2

128 = Bytes per sector

26 = Sectors per track

77 = Tracks per disk

1024 = The allocation unit size (1K blocks

for an 8" disk)

64 = Maximum number of directory entries on

a disk

2 = Number or

tracks reserved for the CPM operating system.

Tracks start at 0,1,2,3,.. so tracks 0 & 1 are for the operating system. The disk

directory starts on Track 2.

You will see this macro at the bottom of the above code listing.

Next we need another table which Digital Research calls a

Disk Parameter Header table or

DPH. This table is somewhat simpler and

contains amongst other things a pointer to the above DPB table.

Again an assembler macro is supplied. For our 8" disk the DPH macro is:-

DPH0: DPH

SKEW6,Floppy$DPB,16,31

SKEW6

Is a pointer to another macro (described below) that describes how the sectors

are numbered on a track.

Floppy#DPB Is a word pointer to the

above DPB for the 8" floppy disk.

16

This is the maximum size in bytes of the disk checksum vector, lets skip for now

31

This is the maximum size in bytes of the disk allocation vector, lets skip for

now also and just use these values

The SKEW6 pointer, refers to a macro that describes the order of how sectors are

arranged on a disk in terms of sector numbering. If sectors were numbered

1,2,3,4..., sequential sector reading would be slow because once one sector has

been read, processed and placed in RAM by the CPU the head has already moved

along a few more sectors on the disk. The system would have to wait an almost

complete rotation for next physical sector to come around. By

"skewing" the sectors this is avoided. For example on a standard 8" IBM

disk the order is:-

01H,07H,0DH,13H,19H,05H,0BH,11H,17H,03H,09H,07H,15H,02H,08H,0EH,14H,1AH,06H,0EH,12H,18H,04H,0AH,10H,16H

Again to save you the hassle of figuring the order out Digital Research provided

a macro:-

SKEW6: SKEW 26,6,0

SKEW26 Is the total number of sectors per

track for that disk

6

This is the skip number for the skew.

0

This is the number of the first sector on the disk.

It turns out that the last number often causes problems. It is usually a 0 or 1.

If you set it to 0 then for all floppy disks in the actual disk "set sector"

code before you send the data to the disk you must increment the value by one.

This is because sectors on floppies are numbered 1,2,3.....

You can set the above to SKEW 26,6,1 and not do this, however its really

important throughout all your BIOS code to be consistent. As we shall see the CF

card/IDE drive BIOS'es number sectors 0,1,2,3 etc. In all my code I

use the 26,6,0 format. I lost a lot of time in the past

tracking a bug like this down! Your disk will appear fine initially but get

messed up later when you go back and forth between disk formats.

OK we are almost there. There is still yet one more table. This is the

Disk Drive Table or

DTBL

This one is simple. CPM3 allows for up to 16 different drives. The

DPH table is just a list of pointers to each DPH for each drive. Any entries

with no drive are set to 0. We have only one drive here.

The DTBL will be:-

@DTBL: DW DPH0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0

When you look at the bottom of the code for the CPMLDR "BIOS" (ZLDRBIOS.Z80)

you will see all of the above combined.

Now in order to have a functional basic operating system we need to splice in

the Digital Research CPMLDR.REL file. This a

disk operating system file supplied by Digital Research that works with our

basic custom BIOS. Remember all we are trying to do here is read in

the main CPM3.SYS file on the disk. The CPMLDR.REL file is set to run at

100H in RAM. It is constructed such that it expects immediately

above it the Loader BIOS jump vectors exactly as they are at the start of

ZLDRBIOS.ASM.

We use the CPM program LINK to splice the two sections together and write them

out as one file CPMLDR.COM.

If you load this program with SID or ZSID and jump to 100H in RAM the above code

should work and come back telling you it cannot locate the CPM3.SYS file on the

disk. (Because we have not done it yet).

However before we get to that we have to do one other thing. We need to get some

way to write the CPMLDR.COM file to tracks 0 and 1 of the floppy disk.

I have written the program ZSYSGEN.Z80 to do this.

It can be seen here. Its essentially a reverse of the EPROM

monitor code to write (rather than read) multiple sectors to the disk.

Finally we need to splice the ZSYSGEN and CPMLDR code together to yield one

"standard" CPM program which I call

ZSYSGEN.COM.

This program on any standard IBM 8" floppy disk will place the above

CPMLDR.com code on the system tracks.

The code is a little bit more complicate than I described above because it has

the option of placing a Banked or Non-Banked CPMLDR.COM file on the disk. For

now everything will be for a non-banked system.

All of the above assembly and splicing can be done automatically by running the

ZSYSGEN.SUB file. This can be see

here.

THE CPM3.SYS FILE.

This file is the heart of the operating system. First we need to decide

how we will layout our hardware. For our first system we will just have a

Console and two IBM format 8" floppy disks A:& B:.

First we will work on the Floppy disk portion of the BIOS. This is contained in

the file 8FL3.ASM. The source code can be

seen here. The BIOS contains

essentially the same tables that I described above and uses the same assembler

macros. However there is one more new table structure it is called the

Extended Disk Parameter Table

(XDPH). The XDPH is in fact nothing more than the above DPH table

except that additional bytes and word parameters are placed immediately before

and after the "regular" DPH table described above. However the exact

placement of these extra parameters is very critical. Here is the XDPH

table I use for drive A:

; EXTENDED DISK PARAMETER HEADER FOR DRIVE 0: (A:)

DW WRITE$SECTOR ;FD SEC WRITE ROUTINE

DW READ$SECTOR ;FD SEC READ ROUTINE

DW FLOPPY$LOGIN$0 ;FLOPPY DISK "A:" LOGIN PROCEDURE

DW FLOPPY$INIT$0 ;FLOPPY DISK "A:" DRIVE INITIALIZATION ROUTINE

DB 0 ;RELATIVE DRIVE 0 ON THIS CONTROLLER

DB STD8IBM ;MEDIA TYPE KNOWN SSSD 8"

;HI BIT SET : DRIVE NEEDS RECALIBRATING

DPH0: DPH SD128$trans,SDSS128$dpb,,

;Bytes 0-24 used by DPH/CPM

DW 128 ;25, 128 Bytes per sector count

DB 0 ;27, Drive Hardware Select

You can see the normal DPH begins at DOH0: Listed above it are two byte

fields (unused here) that the software can use as flags for disk density/format

etc. CPM does not use them. Then immediately above them are four word

pointers to disk the initialization, login, sector read and write routines.

These are the routines you must custom write for each disk. CPM also

adds table values to the bottom of the DPH. In fact from the location DPH0: the

next 24 bytes must never be changed by your custom BIOS. You can add any other

flags or pointers you like below that. I use two in all my floppy disk BIOS'es.

one to hold the sector byte count for that disk format, the other the actual

hardware select byte for that drive.

The relevance of all these flags and pointers being placed at these precise

positions relative to DPH0: is that throughout CPM3, all sector reads and writes

will supply a pointer to the relevant drives DPH in the register pair [DE].

Using the following code:-

PUSHIX ;Save [IX]

PUSH D ;[DE]->[IX]

POPIX ;get XDPH address for current requested drive to [ix]

we can utilize the useful Z80 [IX] register to obtain, compare, or change values

within the XDPH table. You will see a few examples where I have done this

in this simple BIOS. For example the bytes/sector for any disk is

[IX+25].

Take a look over the 8FL3.ASM code to get

comfortable with the above. Don't worry about all the equates at

the start, most

are not used.

You should by now be familiar with the disk DPH, DPB and SKEW macros.

Next we need to look at the 8DRVTBL2.ASM file.

This one is simple. It just contains the DTBL we described above. However

now we have a total of two disks whose DPH's are labeled DPH0 & DPH1 so we see:-

@DTBL: DTBL

<DPH0,DPH1,0,0,0,0,0,0,0,0,0,0,0,0,0,0>