EA, 33, D3, 01, C3, 00, 00

I use the Wellon VP-290 to do this. The code is so

short you can simply enter the bytes directly within its own programming

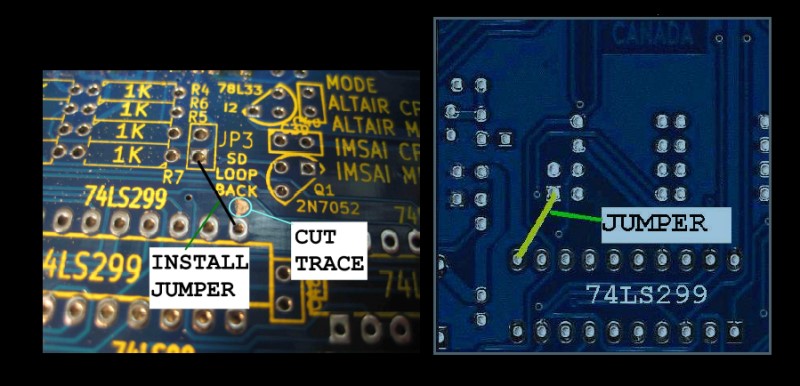

interface. The board need to be configured as a "master".

Unconnected to the front panel (if present) set the following jumpers:-

JP7 1-2

JP6 2-3

JP1 2-3

JP4 1-2

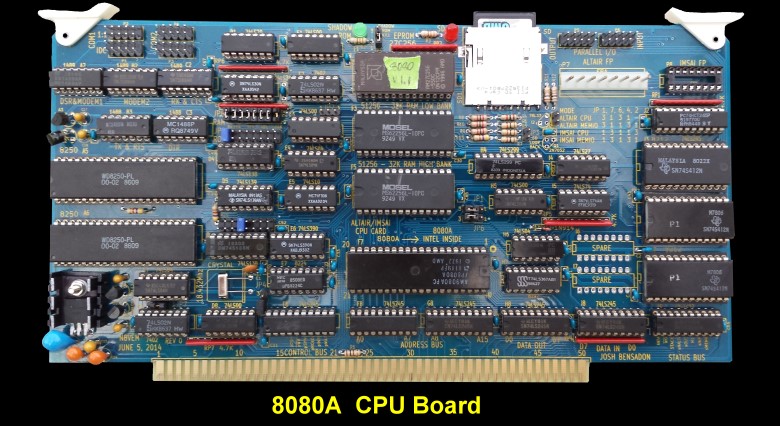

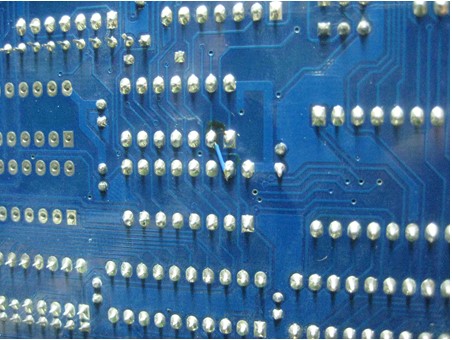

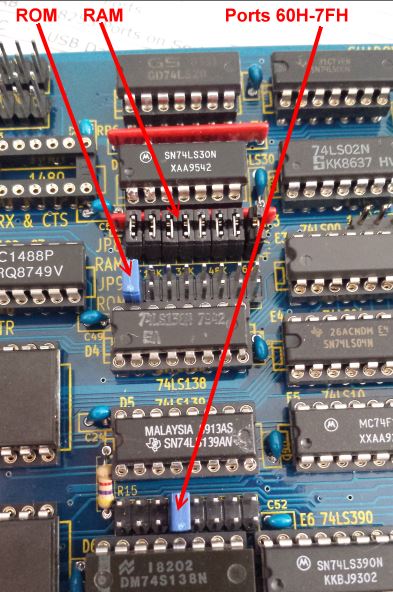

We will place our ROM starting at 0H in memory and utilize the full 64K or

RAM space. So jumper the ROM & RAM jumpers as shown here.

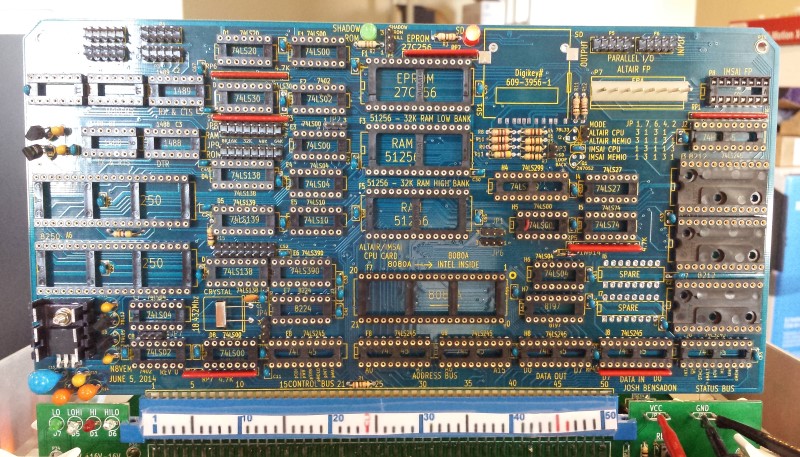

Remember on this board if there is no I/O port jumper, that port address

range is available from other S100 bus boards. In my system the

console I/O ports are 0H & 1H, so no jumper at the first position of JP10.

We will be using the onboard SD card (see below). I have assigned it to the

60H to 7FH ports range. The only other boards I have here that

use this range are the

Lomas Video board and the old

Tarbell cassette board. With the above configuration the

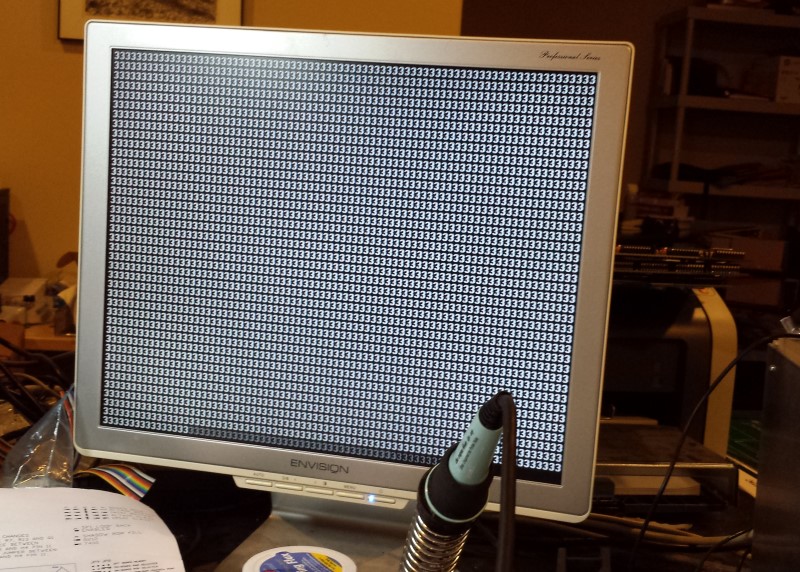

board came up fine displaying data on the console as shown here:-

If you do not see the above output it may be because this board does not

supply the upper 8 address lines for port I/O. Only address lines A0

to A7 are valid. For many old S100 boards this is all that is decoded

anyway. But IEEE-696 boards (and all of our own S100Computes boards),

utilize the full 16 bit address range. Fortunately these

boards have a jumper to restrict the port range to 8 bits. On our Propeller

Console IO board its jumper K5 2-3.

If you get this far you are well on your way to bringing up the

board. At this point you can either hook the board up to your

Altair/IMSAI front panel or if you have one, insert the

SMB. In any case you

need to insure that the S100 bus signal MWRT (S100 pin 68) is being

generated in your system. On the

SMB this is jumper JP11.

Finally this board lets the IEEE-696 Address lines A16 to A23 float.

If you are using IEEE-696 RAM/ROM boards these lines need to be grounded

if you use them. Since the board has its own 64K of RAM this is

probably not a big issue. BTW, our

V2-SMB has a circuit to

ground these lines (when a 16 bit CPU is not being used).

An 8080 Monitor.