A FPGA Disk

Controller

S100 Bus Board

Introduction.

Let me say first --

this are not an easy boards to build! I spent over a year on it with some

different 8 hardware prototypes. The Z80 assembly language is over 8000

lines of Z80 assembly code! The difficulties are not due to complex

FPGA/electronic circuits but rather the large number of possible

software and hardware configurations. The "final" board should be the

last S100 bus disk controller you should ever need! It will handle

most IDE hard drives, most CF cards, most SD cards (with adaptors min & max

sizes). Almost all 8" floppy disk formats (Single & Double Density, Single

and Double Sided). Almost all 5" Floppy disks and 3.5" floppy disks.

In fact the only floppy disk types not covered are hard sectored Northstar

and Micropilis disks. Examples of a CPM3 BIOS are added for some

common disks and formats. In all cases the approach is to vastly

simplified the CPM3 BIOS by having it issues simple one byte commands to the

40mHz Z80 CPU within the FPGA on the board. This controller handles

all disk access including initialization, sector read writes etc. Except for

some tables within the CPM3 BIOS, CPM3 has no knowledge of the disk hardware

-- nor does it care to! Everything is taken care of by this FPGA Disk

controller board.

The early board prototypes started life as self contained S100 bus single

board computers. Indeed this one board in the bus could in theory boot up

and run CPM. This was the basis of molding the system into a

relatively complex hardware setup to present the onboard disk hardware to an

external S100 bus master (or slave) CPU. The bridge

between the onboard drives/software and the "external" S100 bus is via two

S100 bus 8 bit bidirectional data ports. Everything on the S100 bus

side goes across this I/O port bridge. There is no DMA, no S100 bus

wait states etc. This command driven approach makes for very simple

disk operating system BIOS's and is of course completely CPU independent.

In one sense this board is a combination of the hardware on our "IDE

Disk Controller board" first released back 2009 and our

ZFDC Floppy Disk Controller first

releases back in

2010. Well over 400

of these boards have been distributed worldwide! Instead of

using a traditional GAL or Z80 CPU, we utilize an Intel Cyclone IV

FPGA. A Z80 CPU emulator within the FPGA (running at speeds up

to 40MHz) handles all the software. In particular at this speeds

floppy disk sector access is so fast as to be able to read even Double

Density Floppy disk sector data "on the fly" without DMA/wait states etc.

Unfortunately all this comes at a cost of some considerable complexity.

Realizing that many of our members are new to FPGA's I have decided to

present this board in 3 different formats of increasing complexity. In

all 3 cases the same Waveshare FPGA module is used and the exact same

software is utilized.

The boards are:-

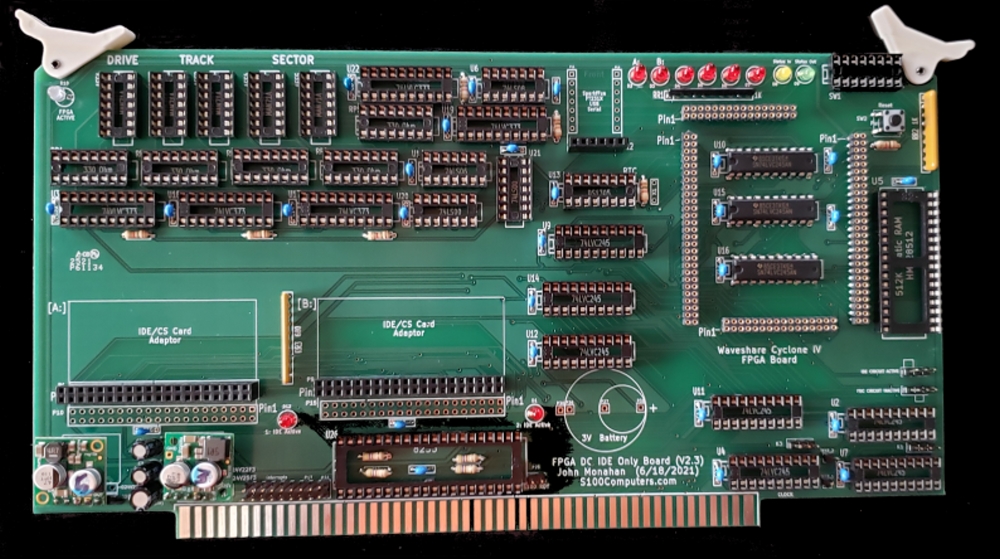

FPGA_DC + IDE Board. This board is in essence an FPGA

driven version of our IDE/CF

Card

Disk Controller board It can be configured into 3 different hardware

"modes" (See below). To help get people started it has a

default mode (Mode 0), where it behaves exactly like the IDE/CF Card Disk Controller

board. In this way you can boot any IDE/CF card version of CPM3 directly

from this new FPGA Board unmodified.

(This unfortunately raised the complexity of the board and its software

considerably and caused me a lot of headaches initially!).

In this mode the actual sector read and writes are done directly via the

S100 bus with the 8255A IO Chip. Any "old" IDE/CF card BIOS does not

know it is talking to a new disk controller. However the FPGA DC Board

actually initializes the IDE/CF card hardware before transferring control to

the S100 bus. A second initialization by old BIOS software does no harm

but actually is not required. The actual sector R/W routines are very

simple (and fast), but are not single byte "command driven" as

the board is really setup for. This mode is there to get users quickly

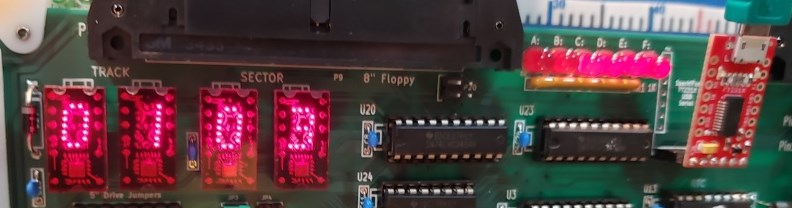

started with a working disk system. As an extra, a 5 segment LED Hex display

always shows the current Drive, Track and Sector. Another mode (Mode

1), allows the IDE/CF/SD Cards to be accessed in a simple one byte command

driven approach.

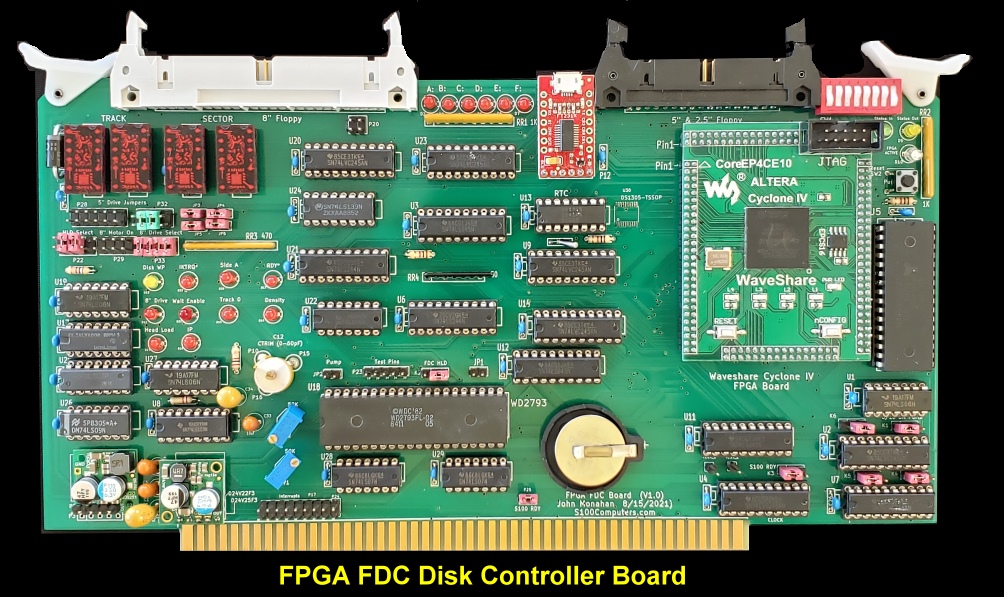

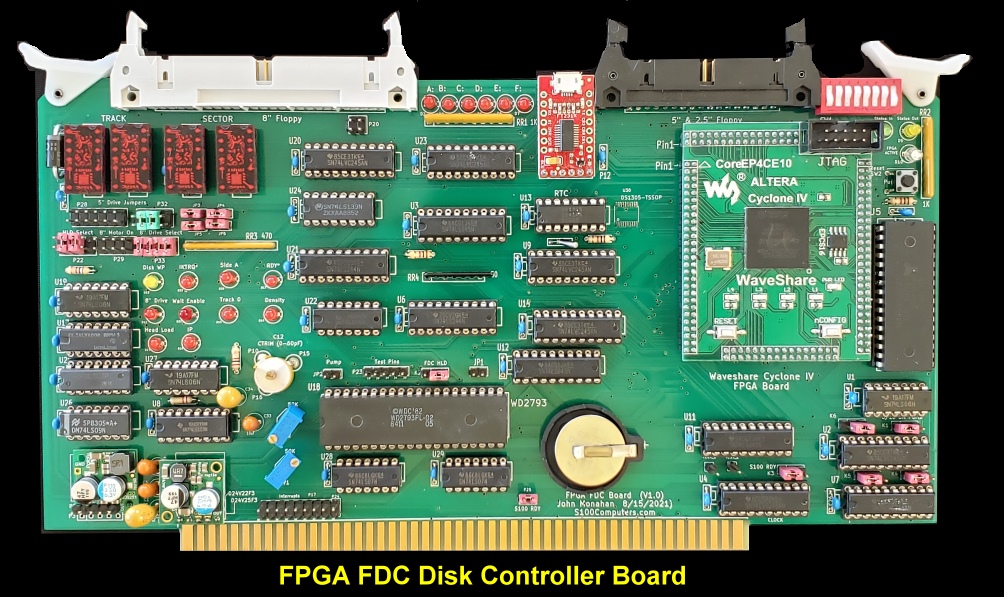

FPGA_DC + FDC Board. This board is in essence an FPGA

driven version of our ZFDC

Controller Board This board interfaces the Western Digital

2793 Floppy Disk Controller to a Z80 emulator within the Cyclone IV FPGA.

The Z80 runs very fast -- for the core disk sector data transfers 40MHz, so

the CPU is not the rate limiting step and so can run in a simple chip status

mode without DMA or wait states. Utilizing the disk parameters table driven

approach of the ZFDC board, any 8", 5" or 3.5" disk format can be

easily utilized. Again understanding what is going on is fairly complicated

but this time the board is completely byte command driven as was done for

the ZFDC Board. Again a CPM3 Single Density Single Sided 8" disk

should boot unchanged with this board. As for the ZFDC board, a 4

segment LED Hex display always shows the current Track and Sector.

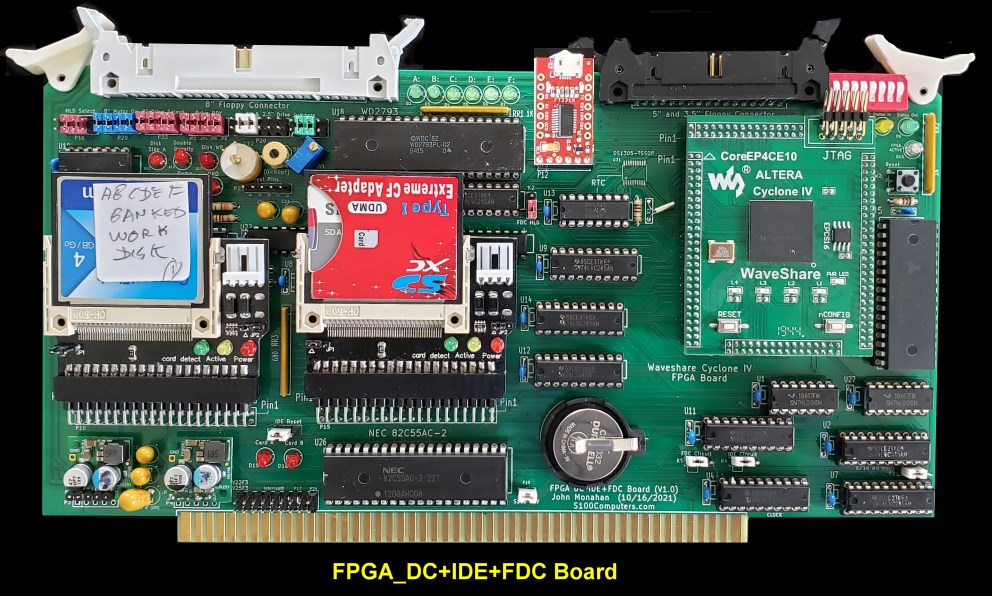

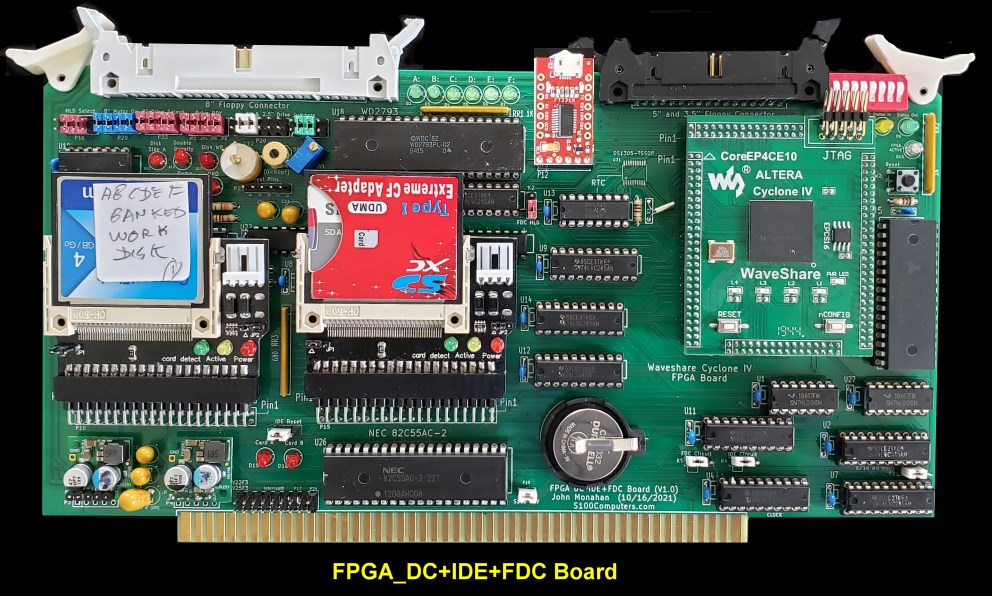

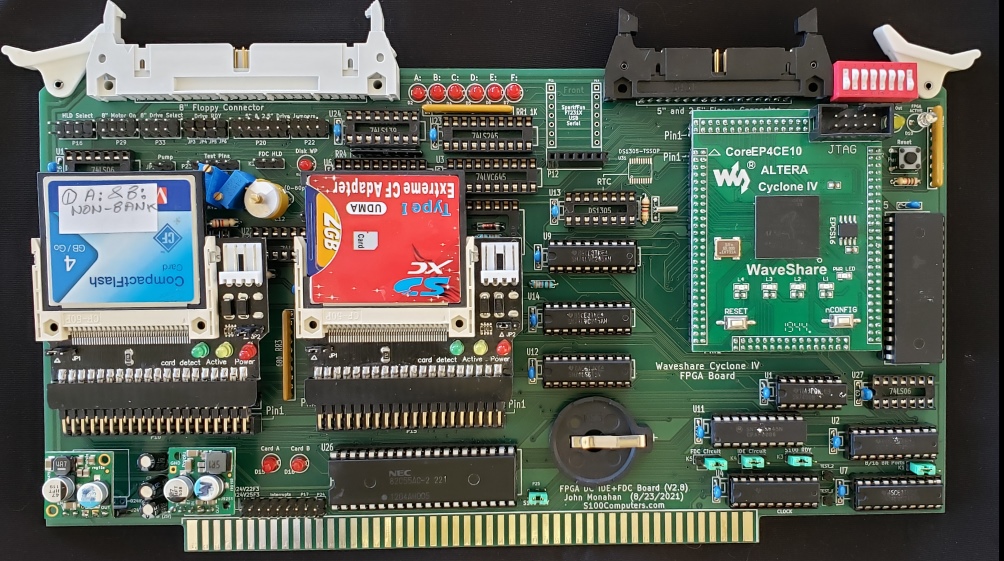

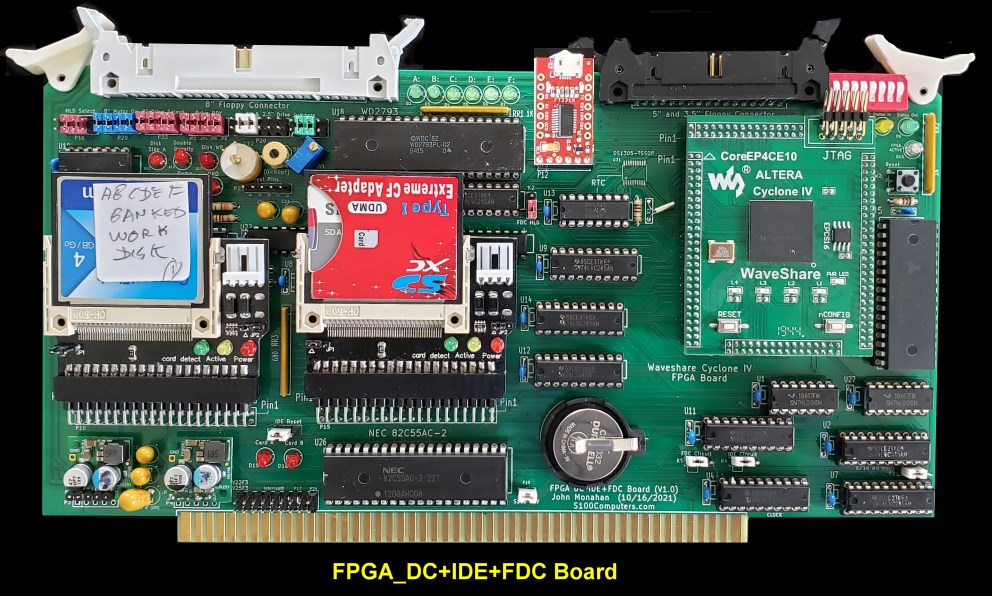

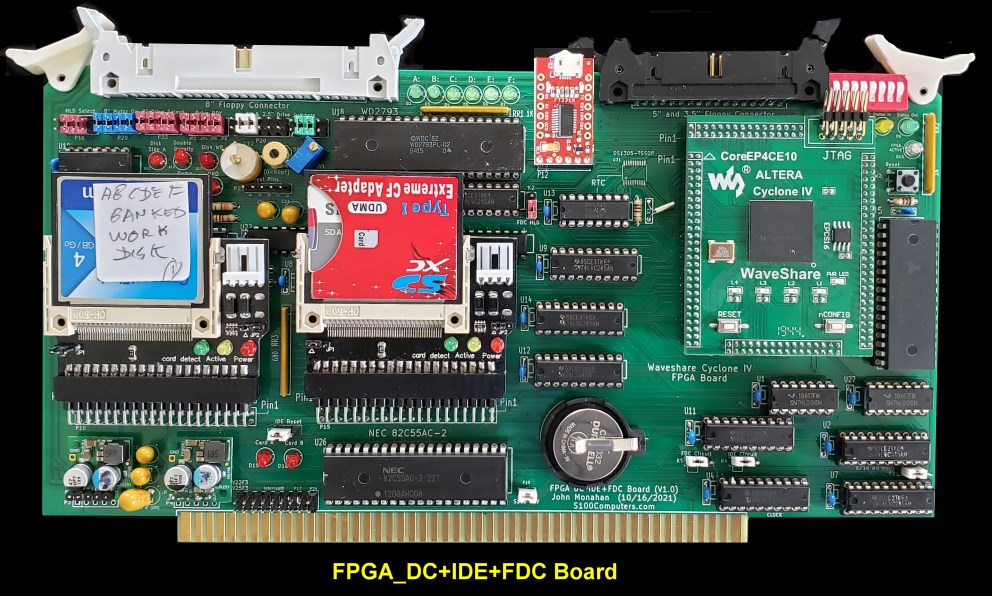

FPGA_DC + IDE + FDC Board. This board is a

combination of the two above boards. Needless to say it is much more

complex. For beginners in particular I highly recommend you start with

the above two boards first. BTW, the same FPGA software is used for all

three boards.

Two jumpers on each board redirects the FPGA to the relevant circuits.

Finally all three boards contain a Clock/Calendar chip which can be utilized

by a CPM3 BIOS to time stamp files.

I will now go through a detailed description of each board and its build

process.

FPGA_DC + IDE Board

In a certain sense this is the simplest board. For one, there is

no disk signal adjustments or a multitude of different disk formats to deal

with.

If you are not familiar with FPGA's you need to read up on them. We have

used them successfully on a number of our recent boards (e.g. a

Z80 and

80286 SBC). Much of what is written here assumes you are familiar with those boards.

There are introductions to FPGAs there as to how to program and use them.

If this is your first FPGA board you really have to read the write-ups on

these boards first.

Please read:-

FPGA Programming for S100Computers Boards

All the text below assumes this.

We will utilize the same

Waveshare Cyclone IV board as we have done in the

past. This board contains all the circuitry to program the FPGA as

well as onboard ROM etc.

The great thing about utilizing an FPGA chip like this is we can program it

to act exactly like a very fast (40mHz) Z80 CPU with its own programmable

ROM. While RAM could also be programed into the FPGA , I have decided

to add an external 256K RAM chip (a

256K HM628512). This is way overkill,

but in the future it would allow the Z80 to provide some sophisticated disk

buffering -- something not implemented in the current software below.

With the high speed Z80

onboard we can provide any S100 bus BIOS access to all disk sectors with only

a few one byte commands. This is the approach we utilized on our

ZFDC floppy disk controller board.

It makes writing (or changing) an operating system BIOS very simple.

One set of commands is used for all the drives, all operating systems and all

S100 bus CPUs. Everything passes through two S100 bus I/O ports.

No DMA is required even the slowest CPU (e.g. a 6502) can easily handle the

data stream. We use a marvelous piece of FPGA software written

by Grant

Searle that emulates a complete Z80 CPU in FPGA code. This on-board CPU

running at up to 40 MHz FPGA Z80 does all the heavy lifting.

The S100 bus simply specifies the drive, track & sector and whether it's a

read or write. That's it!

Unfortunately to do all this we really have to very carefully program the

FPGA, both in terms of ROM Z80 software and actual FPGA circuits. It

absolutely has to be bullet proof with good redundancy in the case of errors. The

good news is we have total control of the FPGA Z80 . It's always in

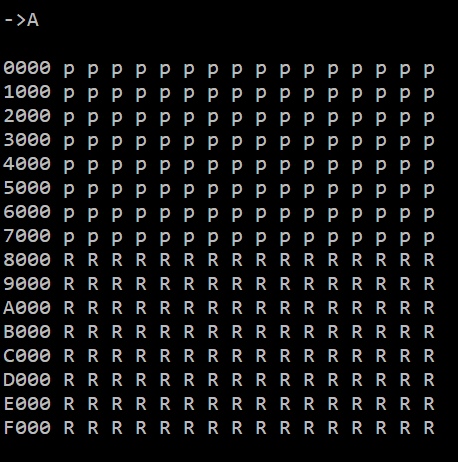

control. We have its total 64K address space at our disposal. We

will utilize the bottom 32K for ROM code and the top 32K for RAM. 32K

of ROM allows us to write quite elaborate assembly language code (~8000

lines of code). So

much so that in fact we have three types of interfaces to the disks on the

board.

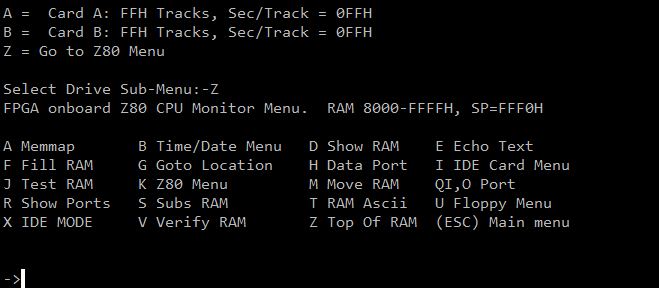

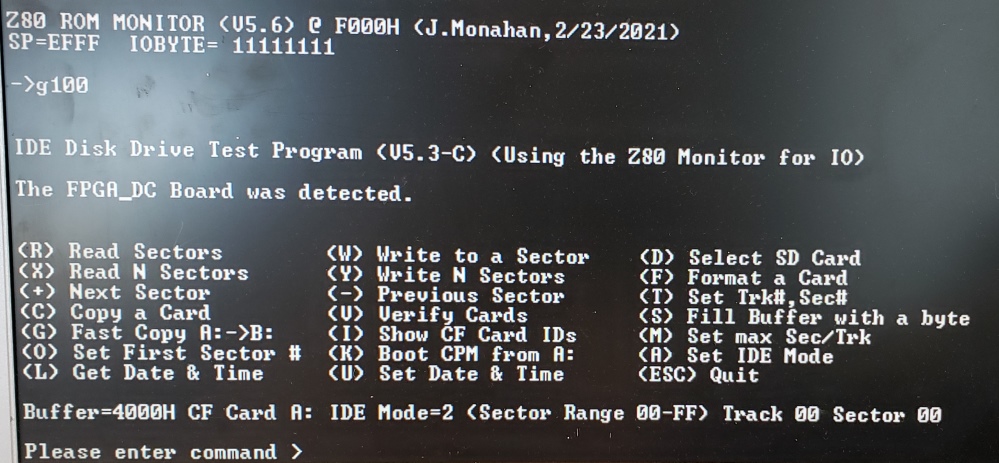

In the Monitor mode, the Z80 can boot up as a typical Z80 "monitor". All external

communications are via an onboard USB port to an external PC software

TTY text window. All the typical Z80 monitor commands you

have seen in the past are there. Here is a picture of the monitor

menu.

Amongst the typical command Z80 menu commands are ones to interface with

the IDE/CF card (and the Floppy disks -- not used with this board).

We will talk about these later, but most are self evident. These

commands simply read/write disk sectors to the onboard RAM on the board

itself. Any S100 bus CPU is completely unaware of this process.

While its critical to the board build/debug process, for an S100 bus

CPU/operating system it is not utilized.

The Disk Controller Mode

of action is the one we normally use when the board is

built. It completely bypasses the above monitor and simply looks at

two I/O ports on the S100 bus. From an external point of view that's

all the S100 bus operating system BIOS sees. The FPGA_DC board on power

up and after initialization simply looks at these ports waiting for a

command (byte) sent from the S100 bus CPU. It

then kicks into action doing whatever 8 bit command the S100 bus sends it.

This is the communication gate between the two systems. It has

to be simple and fast. There is a status port and data port. The

status port bits set/reset automatically depending on the data process.

The complete circuit resides within the FPGA and its Z80 module. The

S100 bus provides the sINP, sOUT, pWR, and pDBIN signals together with the

S100 bus data in/out lines to the FPGA. All S100 bus signals are

switched to the 3.3V levels required by the FPGA with 74LVC245 IC's. The

FPGA Z80 monitor can be configured as we will see below to show in real time the commands being

executed., which drive, track, sector is been utilized etc.

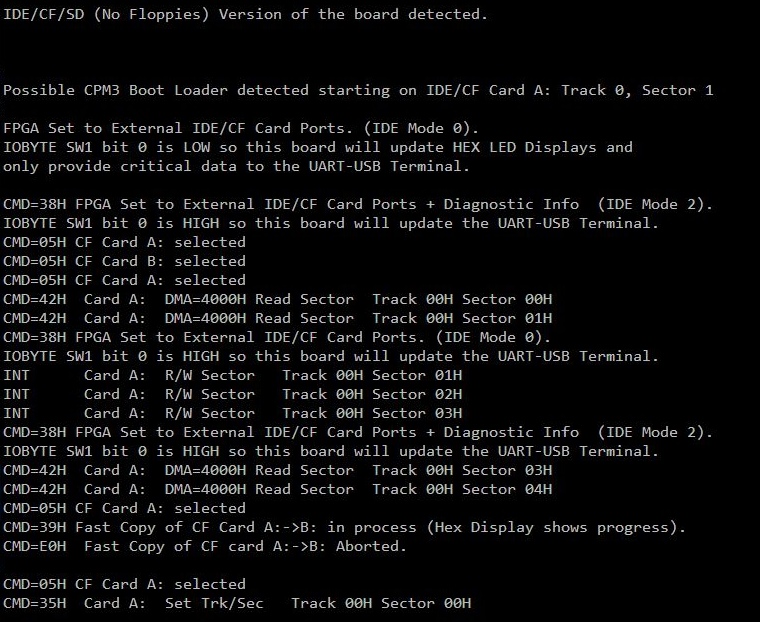

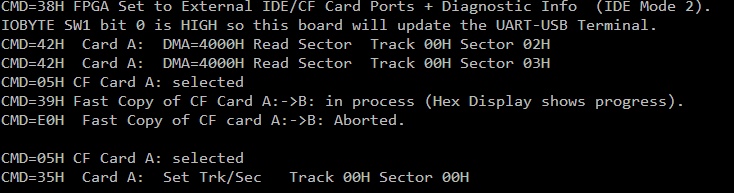

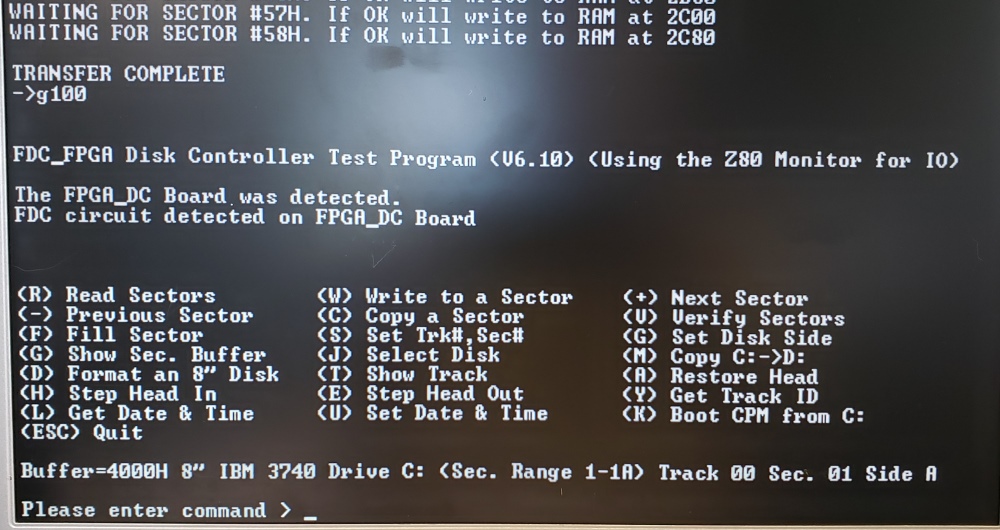

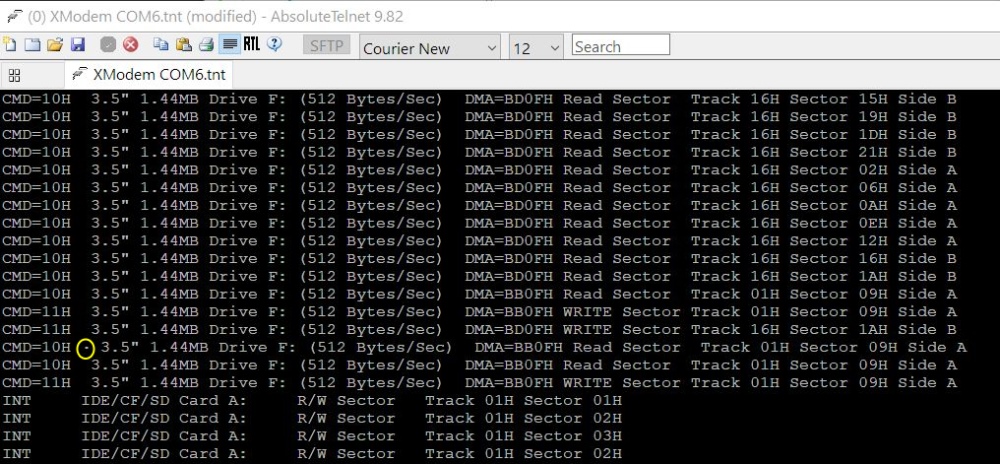

Here is a snap-shot example of the display coming over the USB port:-

This stream of messages will come over a USB port from the board continuously as you boot

and run a disk operating system. This makes BIOS debugging easier. If

bit 0 of the IOBYTE port (SW1) on the board is open the board runs at full

speed but no "breadcrumbs" trail is sent.

The

FPGA_DC.bdf contains the FPGA "schematic" for this and all the

modules within the FPGA. Its fairly complex and should be studied

carefully to understand how this board works. That said, everything

within the FPGA can be treated as a "Black Box" in terms of getting the

board to operate as a disk controller board. You should not have to modify

any of the circuits for normal use.

Within this Disk Controller Mode there are 3 sub-modes in

which the IDE/CF card part of the board can work.

IDE Mode 0.

In this mode the IDE circuit acts identically to the original dual IDE/CF

board mentioned above. The 8255 appears on the S100 bus exactly as for that board.

All software (e.g.. a CPM BIOS), works unchanged. You should be able to

boot any operating system on your old CF cards directly in this mode. This

comes at a price. There is limited diagnostic real time information

passed back on the USB port terminal. The external 8255 port writes do

trigger an interrupt in the FPGA Z80 so it displays the current drive, track

and sector being accessed -- but no more than that.

IDE Mode 1. In this

mode the IDE/8255 circuit is brought under the direct control of the FPGA.

This mode will not work with the old CPM3 BIOS software - unmodified. All BIOS functions

are sent to the FPGA with a few simple Byte commands. All CF card

initialization, drive, track, sector requests can be contained in a few very

simple commands. This exact same command structure approach is used

for all the Floppy BIOS requests as well. In IDE Mode 1 a more

extensive run time display of drive access is sent to the USB port terminal.

IDE Mode 2. This mode is a hybrid of modes 0 and 1.

The IDE circuit is again external to the FPGA but more diagnostic

information is passed back to the FPGA. Card initialization and checkout for

example is still done within the FPGA. For this mode any current BIOS

will need to be slightly modified. The changes are relatively quick and

simple however.

In all cases the BIOS routines for all types of disk access is the same.

Its essentially as we have done for the

ZFDC Floppy disk controller board.

Here are a few commands as examples:

CMD$SEL$DRIVE EQU 5H

;(Re)select an already Initilized drive

CMD_SET_TRACK

EQU

7H

;This will set head request to a specified track

CMD_SET_SECTOR

EQU

9H

;This will set sector request to a specified sector

CMD_READ_SECTOR

EQU

10H

;Read data from the CURRENT sector.

CMD_WRITE_SECTOR

EQU

11H

;Write data to the CURRENT sector.

The important concept to remember with this board is the

same commands are used for

all drives/cards (IDE,

mini SD, micro SD) and as we shall see later for the FDC version of the

board 8", 5" and 3.5" drives). The operating system BIOS

does not have to know anything about the drive initialization, track/sector

seeks etc. As you might expect the is a slight overhead involved

for disk access with this approach. Since the FPGA_DC Z80 is running

at 40MHz for floppy access the bottleneck is always the disk drive -- even

for high capacity double density disks. For the IDE/CF/SD drives/cards

there is a slight delay -- about 2X for sector R/W's. This is unnoticeable

when running CPM3 but does show up in for example a "pure" disk copy of one

card to another. This is why we have IDE Mode 2. In this mode

the actual core sector R/W routines reside in the (CPM) BIOS.

The IDE/CF Card Interface.

For compatibility with the original IDE/CF Card this board also contains a

two IDE interfaces. I brought across

the exact 8255A circuit utilized on our

IDE board. At first this might

seem unnecessary. Certainly an 8255 circuit can be formulated within the

FPGA. However when you total up all the external FPGA pins require for

the 8255 "emulator" and the fact they have to shifted to 5V levels and

they have to be bidirectional ports (all 3 of them), the board real estate is

best served with a single good old fashioned 8255A. Also this makes the

FPGA Z80 code very easy since the code used in all our prior Z80 monitors

can be spliced in directly.

Both the SD and CF cards have way more capacity than CPM can be configured

for and possibly for MSDOS in some cases as well, so in most case we will

utilize only the early sectors on the "drives".

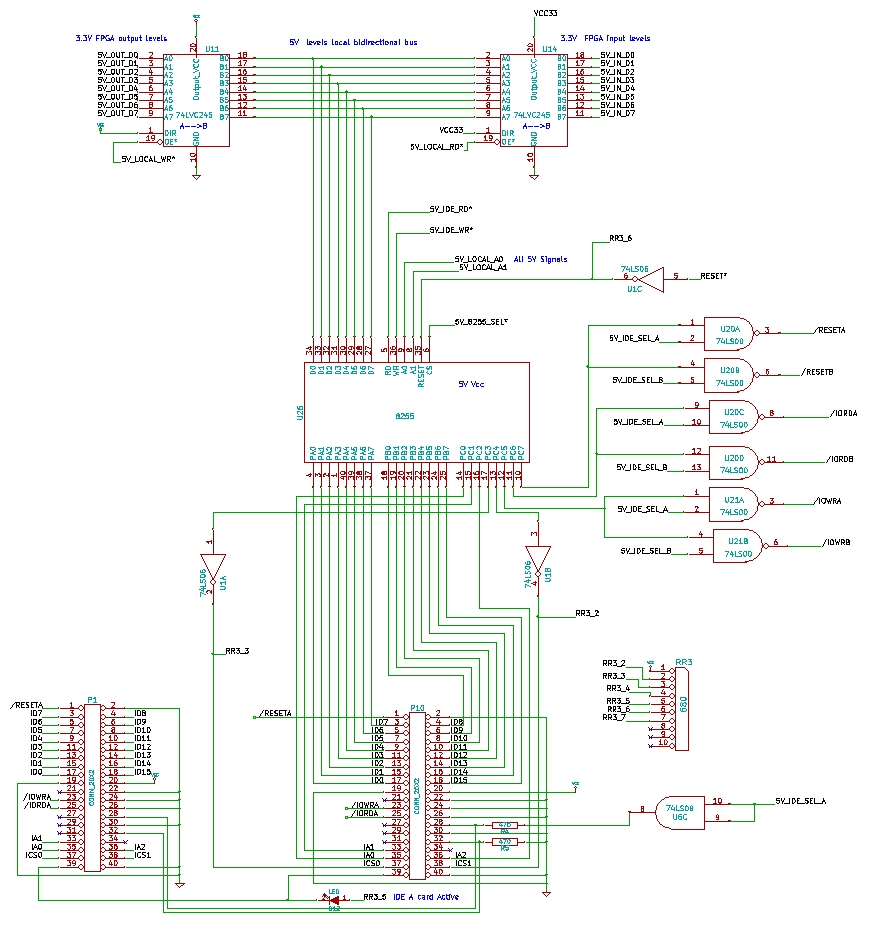

Here is the circuit for the 8255A based IDE/CF card interface on the board:-

In this day and age you are probably not going to use a real IDE hard drive with

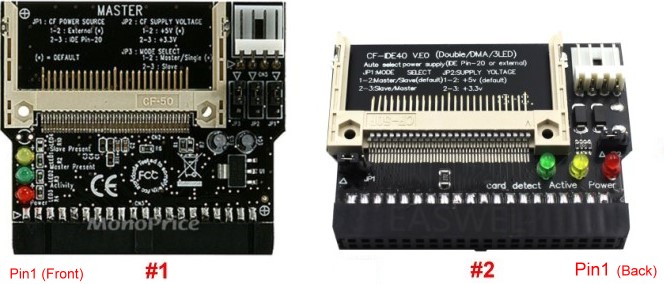

a cable (but you can). Instead the drive is built to accommodate an IDE to CF card

adaptors so an actual CF cards can be used.

They typically cost about $6-$10. I have been using the "SYBA Multimedia IDE to CF

Adapters". We will plug the above adaptor into a right angled 20X2 row of 0.1" pins and

that into a 20X2 female connectors in P1/P9

and P15/P9 (see below).

Since the original IDE/CF Card board came out (in 2004)

SYBA Multimedia has come out with a smaller version of the adaptor. It

behaves exactly the same BUT the IDE connector orientation has been flipped

around. As you look at the front of the adaptor pin 1 is at the back top row

on the right (#2 below). This adaptor needs to be plugged into

P1 and

P9. The older

adaptors plug into

P10 and

P15. Be sure you

add the adaptor to the correct socket. If you use the "old" adaptor

(#1 below), its best not to add the socket for the new adaptor to positions

P1 and

P9.

To utilize SD cards in early designs of this board I utilized SPI SD card

adaptors such as the

Adfruit or

Sparkfun Adaptors. While they worked

fine, actual card access was 10X slower that for CF Cards.

This is due to the single bit SPI public domain interface rather than

the 4 bit licensed interface. Fortunately again there

are IDE to SD card adaptors that completely take care of the complex process

of SD card initialization and access at CF card speeds. Here is a

picture of the one I currently use.

There are also mini to micro SD card adaptors that fit into these units.

So our IDE sockets can accommodate either:-

A Ribbon cable connected "real" IDE hard disk.

A CF Card

A Mini SD Card

or a Micro SD Card.

As far as the software is concerned (see below) all behave the same.

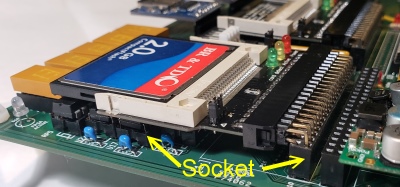

Board Height.

While on adaptors and sockets, there is one major decision you have to make,

and that is the spacing distance between this board and the next board in

the S100 bus. You can either add a 20X2 female socket and a

"standard" 20X2 right angled dual row header to connect it to the adaptor.

This raises the adaptor above the board so that the HEX LED display chips

can be placed in IC sockets, (see picture below). Alternatively

you can use a special 20X2 right angled dual row header to connect it to

the adaptor directly. This is a tight fit. You must use the longer

pins for the IDE adaptor, the shorter pins just make it to the back side of

the board. In this case the HEX LED display chips should be soldered

directly to the board (see picture below). A better socket is the (DigiKey #

S2141E-20-ND) socket which has longer pins. . This makes for a nicer low profile

board with plenty of space before the board in front of it.

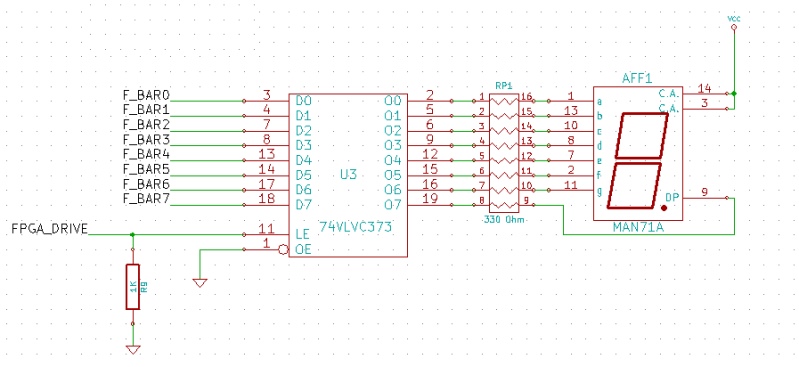

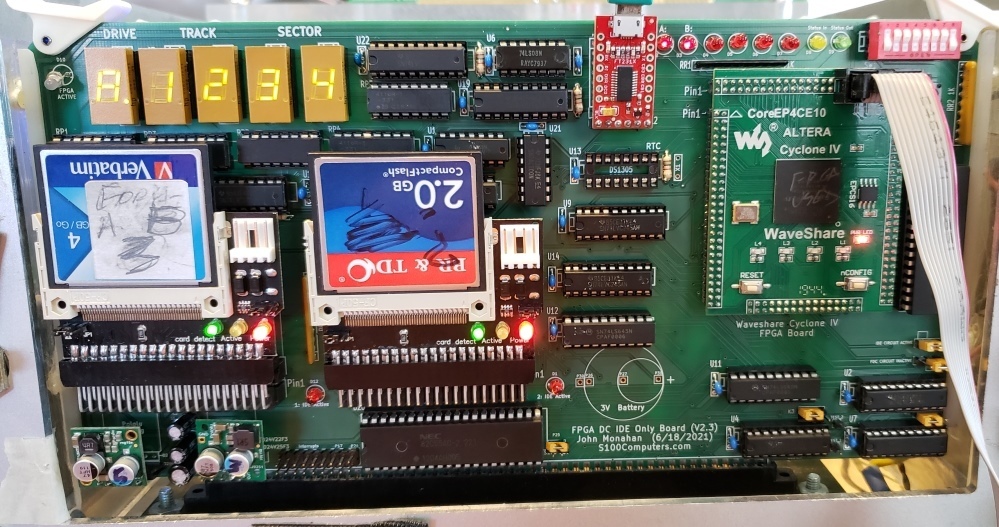

The Drive, Track, Sector LED HEX Display

Interface.

While clearly not essential for the board to function, it's nice to

always have a runtime display of the actual drive/track/sector the BIOS is

working on. In the past we used five TIL 311A LED HEX display on our

IDE and

ZFDC boards. These are

wonderful HEX display LEDs. They convert 4 bits directly into the characters

0,1,2...E,F. Unfortunately they are no longer manufactured by HP and

are in short supply and are thus expensive. The also tend to burn out and

are

power hungry. All modern day 7 segment displays only

decode the digits 0-9 from a 4 bit nibble. In order to "hammer them

into shape" you need to address the 7 segments directly starting with the 16

possible 4 bit nibble values. Trivial to do in our FPGA Z80, but you

also need to latch the outputs for each digit (using a 74LVC373) and drop the

current with an inline resistor network. The 74LVC373 also up's the voltage to

5V. Here is the circuit for one digit.

A very straightforward circuit but unfortunately requiring some 15 IC's for

all 5 Hex LED displays. I could

have used some SMT chips but I know some or our users have difficulty

soldering these. This circuit uses most of the space

on the right hand side of the board. You will see that all 5 digits are

latched in place with separate digit lines from the FPGA. They are not

continuously sequentially scanned in -- saving a major drain on the Z80 overhead. This

gives a nice very steady display.

Notes on CHS and LBA Addressing

On a PC

(at least the early ones), sectors are defined is terms of Cylinders,

Heads & Sectors (CHS format). Parameters in early MS-DOS versions were passed via

software interrupt INT 13H for sector reads and writes. INT 13H

designates sectors in a somewhat convoluted way (for historical reasons),

parameters passed are always as follows:-

AH = 02h

AL = number of sectors to read/written (must be nonzero)

CH = low eight bits of cylinder number

CL = sector number 1-63 (bits 0-5)

high two bits of cylinder (bits 6-7, hard disk only)

DH = head number

DL = drive number (bit 7 set for hard disk)

ES:BX -> data buffer

Because only 16 heads are allowed with this format, a

hard disk can only get to 512MG in size. This is not a problem

for 8 bit CPM systems since disk capacity was always less than 10 MG. To go

to higher disk capacities with later version of MSDOS, the PC BIOS's

utilized the so called "LBA" sector addressing mode. In this

case sectors are numbered on the disk as just one long number. Starting at 0

and working upwards. There are no tracks or heads. We used this format on our IDE/CF

Card board and will use it here as well.

CF cards can be accessed in both CHS and LBA modes. Our FPGA code assumes

all access to the CF card is in LBA mode, starting at sector 0,1,2,3...

SD cards don't even have the CHS mode option. All sectors are accessed

0,1,2,3...

However for CPM (and MSDOS) BIOS software we will work with drives, tracks

and sectors. We will allow for 2 drives of 0FFH tracks and 0FFH

sectors. All sectors will be 512 bytes in size.

For ease in debugging etc. the 5 digit HEX LED display will display the

current drive, track, sector being accessed in this format. The

operating system never has to know about the CHS to LBA translation taking

place within the FPGA.

Here is a typical display:-

| |

|

This would be the IDE CF card A: with the current sector being Track 12

sector 34.

Step By Step Building the

FPGA DC + IDE Board

The build instructions are fairly simple for this board but because it is a complex board building it should not be rushed. As always, first examine the bare board carefully for scratches or damaged traces, use a magnifying glass if need be. A broken trace is almost impossible to detect by eye on a completed board.

Solder in all the required IC sockets,

resistors, resistor arrays, capacitors, jumpers, and the Pololu 5V and 3.3V voltage regulators. Please be sure you put the

resistor arrays in with the correct orientation of pin 1, (the square pad). An incorrect

orientation is one of the most difficult things to detect/debug on a board

if not noticed. Check their values

before soldering (they are difficult to remove). Insert all jumper arrays.

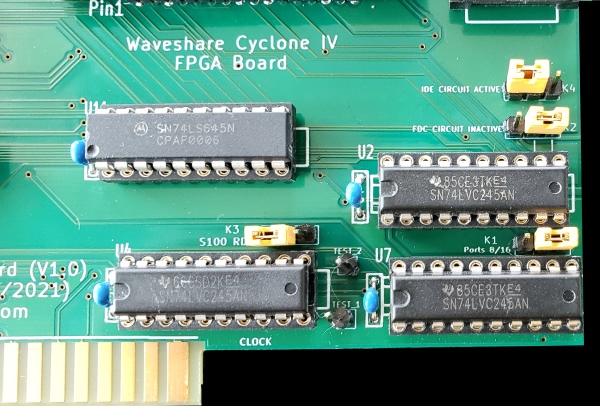

There appears to be a few variations of

the 74LVC245 20 pin DIP level Shifters chips with "A", "AN" etc. after the

245. As best I can tell so long as they are 20 pin DIPs they are

all OK. I use either Mouser chips # 595-SN74LVC245AN.

The WaveShare Cyclone IV adaptor can be obtained directly from

Waveshare

or

Amazon

The WaveShare unit uses unusual 2mm dual row female pin connectors. Unlike

to normal 0.1" connectors these are quite rare an expensive (Digi-Key

#S5750-30-ND). You need to carefully cut them to size, carefully cutting off

the extra pins with a wire cutter. Better sockets are available from Mouser

(Preci-dip 833-87-038-10-001101) as part 437-8338703810001101 for

$3.04 each.

Please note the Digi-Key #S5750-30-ND sockets

for the WaveShare adaptor are quite tricky to fit on to the board. I

found the best way to do it is (after trimming to size), push them half way

on to the adaptor pins and then wiggle them to fit the whole unit on to the

S100 board. Figure on spending 10 minutes on this step!

Do not solder them to the board first and then try and press the adaptor

down on them. They are very fragile and internally the leaves will

bend if socket angles are not exactly correct. When in place, check

each pin is visible on the back of the board before soldering. Only

then solder all around. Add as little solder to each pin as possible -

the narrow pins have a tendency to wick up solder internally. The

Mouser ones don't have this problem but you need two of then for the

FPGA side pins. All sockets need to be trimmed to the requires pin number.

The 2mm spaced male pin headers are DigiKey #0877584416.

One final point here, you will see that many traces go between the FPGA

socket pins on the front of the board. I always worry that the socket pins

during soldering would melt the varnish and contact one of these traces. So

I always insert the sockets just enough to see the pins on the back side of

the board. In other words the socket is slightly above the board.

Try for at least a papers thickness of separation at least between the

socket and the front side of the board.

BTW, to remove the FPGA adaptor, leaver each

corner up a little going round and round. The first time its quite difficult

to get the adaptor out. It gets easier with time.

I use the Adafruit USB serial Adaptor,

but the equivalent SparkFun unit also works fine.

Note there are two sockets for the Pololu 5V and 3.3V regulators. While the older ones

(D24V25F5

and

D24V25F3) are still available

and use P3 and P4, it seems Pololu is suggesting users use the newer

D24V22F5's

(5V, 2.5 Amp) units, it has a different pinout, use this one in P2

(not P3). More recently

they also added the equivalent

D24V22F3

3.3V regulators. Unfortunately in their wisdom they again changed the pinout

connections. You

must use the Pololu

D24V25F3

3.3 V regulator in P4 or the D24V22F3 regulator in

P21. Be sure you get these regulators/ correct. To be safe once inserted, check

the voltage in your system on a 5V and 3.3V IC, (see the schematic) with no

chips yet inserted on the board. 5V and 3.3V going to the correct pins of the FPGA

adaptor. (5V going to the 3.3V pins will blow the unit!). Please

note Pololu has come out with more 5V and 3.3v regulators. Please

examine the pinouts and match them with the board sockets.

Unfortunately the newer 5V and 3.3V units look exactly the same on the

surface. Presumably some of the internal resistors are different to give 5V

and 3.3V.

Note recently the above Pololu regulators have gotten hard to find and have

become expensive. Pololu now has more options to pick from.

Examine the pinout of any of their 5V or 3.3V regulators and place

them in one of the two sets of slots above.

When adding the LED's be sure to orient them correctly. (Usually the longer

lead in the square pad).

The 20 pin DIP version of the

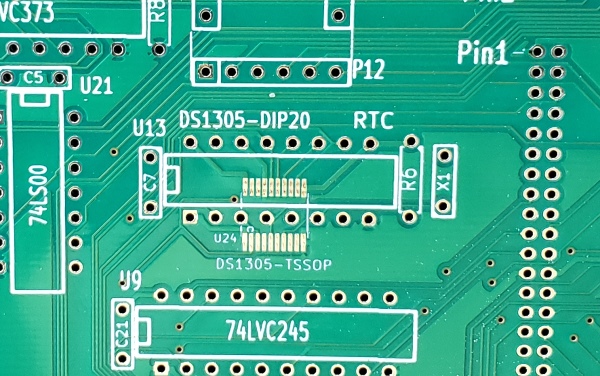

Maxim RTC chip is

currently in short supply. In case people cannot obtain one I have

added a footprint for the SMD version of the chip as well. They

both work exactly the same. Be sure not to add the U13 DIP socket if you

intend to use the SMD chip.

There are many types/sizes of 3V coin batteries and adapters. Jameco sells

many holders. The 1" #236996 with a CR2032 is common. So long as it's 3V

types don't matter. The RTC chip battery should last for years!

Please take care to not "slobber" solder on the sockets. They are very

closely spaced on this board with vias often close to a socket pin -

particularly for the FPGA adaptor sockets.

At this point insert the board into your system and check your S100 bus Z80 monitor

boots fine. If not check for solder bridges etc. Also do one last

check to be sure every IC solder pin is soldered. Seems trivial, but I

don't know how many times I got caught with this error.

Next we need to solder in the three ICs U10, U15 & U16

directly to the board. If

possible use known working 74LVC245's from a previous board. You don't

want to have to remove a faulty one later. Take care not to scorch the

chips. If possible have the chip pin just barely show on the back of the

board for soldering.

Here is a picture of (a

prototype version) the board at this stage:-

If you are not completely familiar with programming the Cyclone IV FPGA

please study in detail this write-up

Programming a Cyclone IV FPGA.

Carefully insert the WaveShare

Cyclone IV adaptor in its sockets. Power on the computer.

"Virgin" Cyclone IV Adaptor boards from WaveShare may have a FPGA

preloaded with a program (in the

EPCS16 Flash RAM) that already that pulses its

4 onboard LEDs. Previously programmed by you FPGA boards of course will

not.

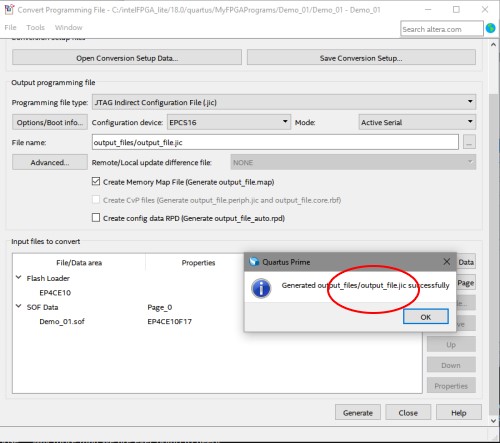

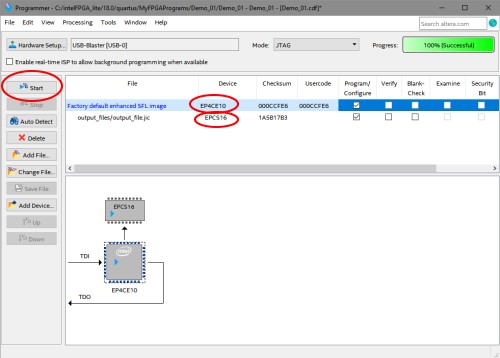

In any event open the Quartus FPGA_DC project folder (the expanded

FPGA_DC.ZIP download, see bottom of this

page) and program the FPGA using the

FPGA_DC.bdf

file.

Now would be a good time also to study in detail the

FPGA_DC.bdf file to

understand how the board "works". Remember the FPGA utilized its own

internal 30-40 MHz Z80 and so utilizes a .HEX file for its ROM code. This

.HEX file resides in the FPGA_DC\ROM_HEX_FILES sub-folder. The source for

this file is FPGA_DC.Z80. You don't need to alter this file for

normal use but its also provide in case you need to.

Should you wish to "play around" with this file, I supply it and its

components in the folder

FPGA_Disk_Controller Board where

it can be assembled on a

PC using Altair.com etc.

Be sure to move the final FPGA_DC.HEX

file to the Quartus FPGA_DC\ROM HEX FILES

folder when done as Quartus is counting on finding the

FPGA_DC.HEX file there (or readjust the ROM Module Properties in

the .bdf file)

If you program the onboard Cyclone IV FPGA at this point nothing will happen

except the LED D10

(Board Active) LED will pulse. This must happen. Do not go further

unless it does.

Next install the following IC's:-

U2, U4, U7, and the RAM chip U5.

To activate the IDE/CF Card circuit within the FPGA jumper K4 1-2 and K2

2-3.

IEEE-696 16 bit S100 bus port IO addressing is assumed (the upper 8 lines

being zero) for this board. This can be easily bypassed within the FPGA

(Jumper K1 1-2). Do so if your CPU board does not zero the high

address lines for port I/O. To be safe we will jumper K1 1-2 for now. Note

16 bit CPU's will probably require K1 2-3.

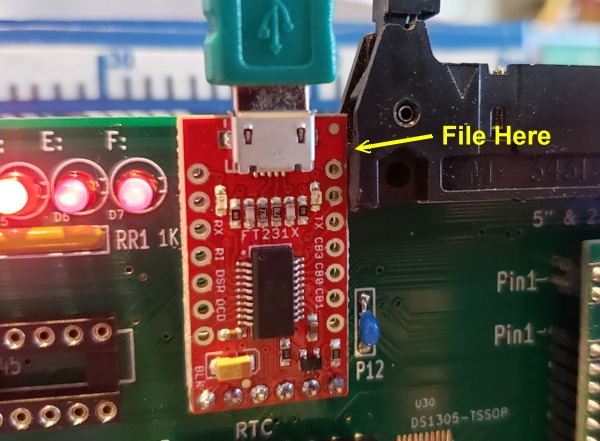

Install the Sparkfun

FT231x USB adaptor. Note it has a jumper on its back for 3.3V operation,

use 3.3v not 5V. You can

solder the adaptor directly to the board or use sockets. See the

section above on soldering sockets. I suggest direct

soldering. Note the USB FT231x

adaptor actually has 3 sockets. The two side ones are not used here and are

only there to steady the adaptor on the board. I use only pin 1 in each

case. You can also use the

Adafruit CP2104 USB adaptor equivalent adaptor. Perhaps it's just me, but sometimes

I've

had problems getting this adaptor to link up with my PC's.

The default software on this board assumes a USB port running at 38,500 BAUD, 2 stop bits, no parity.

(This can be changed within the FPGA_DC.bdf file). There are a number

of Windows/PC programs you can use to receive and display the data. I

like

Absolute Telnet

from Celestial Software, but others are free.

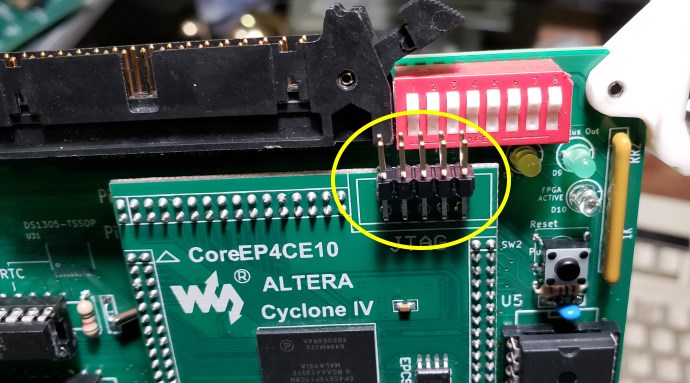

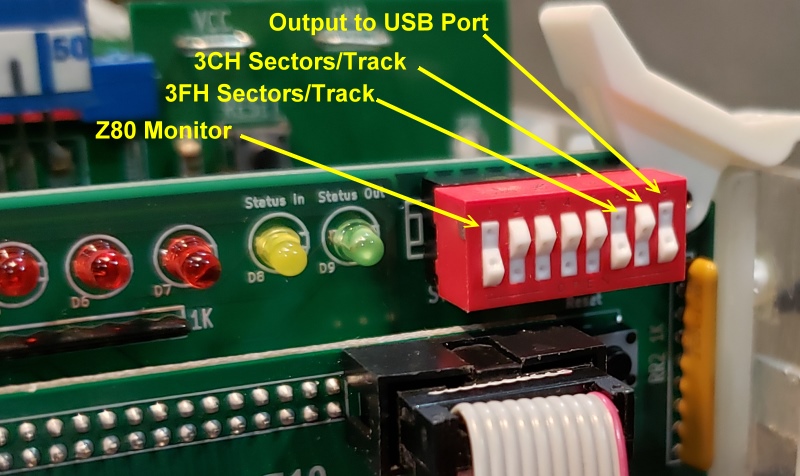

The board has an "IOBYTE" switch (SW1),

which defines what the FPGA_DC Z80 monitor

does on power up. The default mode, all switches open, (no switch) causes

the Z80 monitor to get

0FFH

from port

46H after a reset. This is the boards normal mode of

operation but we will not use it yet. Currently only two

switches are utilized:-

Bit 0 (Pos

8), (Reading left to right), when closed, (xxxxxxx0H),

this causes the board to send status information to the USB port during

every step of its operation. A remote PC can thus watch how commands sent

from the S100 bus are operating during "disk" operations. This slows down

the Operating System BIOS a little but is invaluable for debugging etc. When

open no commands are sent.

Bit 7, (Pos1),

when closed, (0xxxxxxxH),

this causes the board upon reset to bypass the S100 interface and go

directly to its onboard monitor. The onboard monitor contains all the

"normal" commands for a Z80 CPU, display/change RAM, ports etc. but it also

contains two very special command I

and

U.

Place the board in the S100 bus with

SW1 positions

8

and

1

closed. Power up and again load the

FPGA_DC.BDF

file into the FPGA. Upon reset the FPGA will boot up its Z80 monitor. You

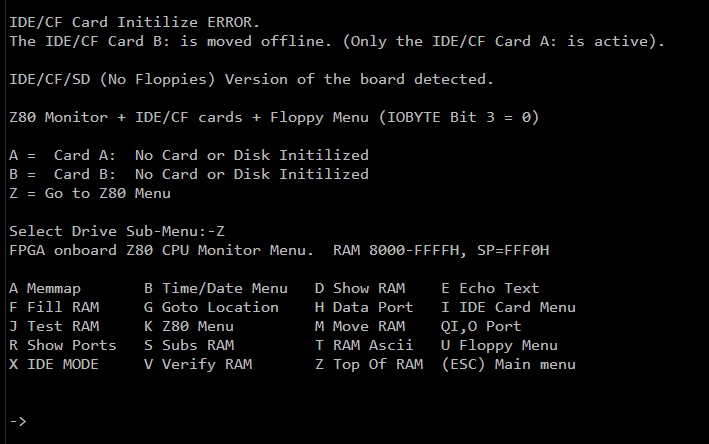

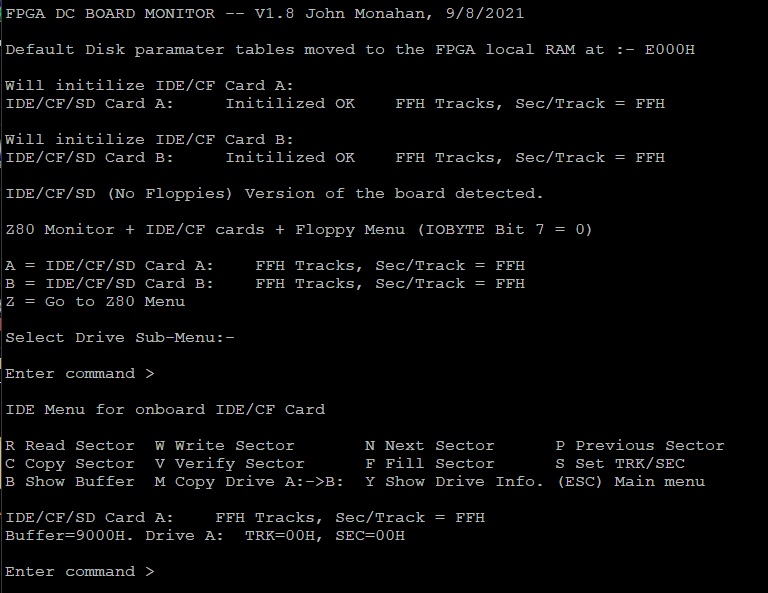

should see the following display:-

For now just use the Z command. This will bring you directly to the

FPGA Z80 CPU monitor. You should see the following:-

Most of these commands should be familiar to our users. (The

X command BTW,

is not yet implemented).

Play around with the regular Z80 monitor commands (except

I,

U and

X)) at this stage to get

comfortable with the interface.

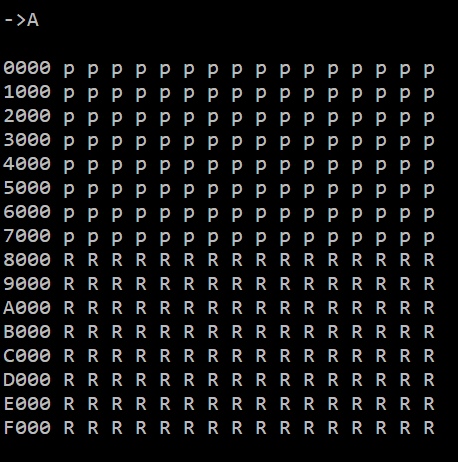

For example the A command will show

you the "Memory Map" for the Z80 on the board.

Next we will install the IDE/CF card circuit.

Install the 82C55, U26 chip.

Add U26 (I have had a number of CF card initialization problems with some

82C55A's e.g. NEC and OKI chips. The only reliable chip I find is the

NEC 82C55AC-2).

Use this (common) chip.

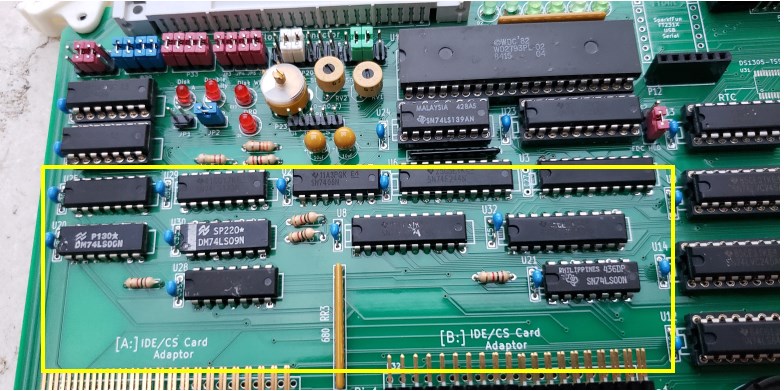

Add U9 and U12 and U11 and U14. Note U12 & U11 are regular 74LS245s (or better 74LS645s).

Add U1, U6, U20 and U21.

Jumper K1 2-3, K3 1-2 and P25.

Install one or both of your IDE adaptors each with CF cards.

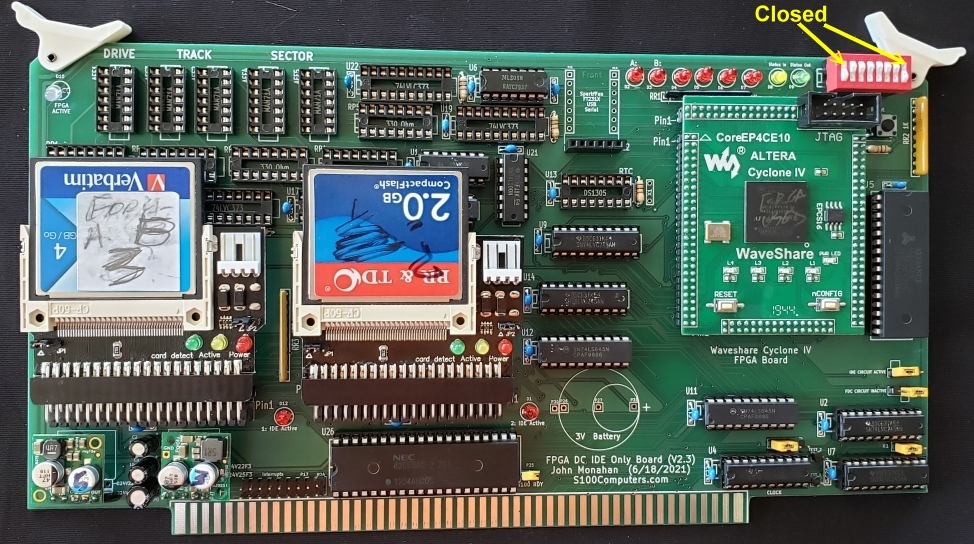

Power up, load up the FPGA again and from the USB port menu select the "A"

menu option.

The board should look like this at this stage:-

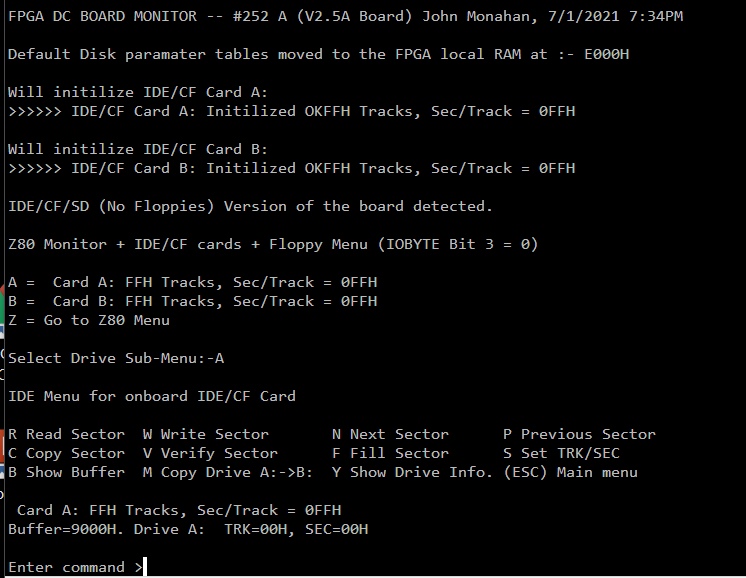

The IDE Sub-menu should come up as shown here:

What remains is the circuit to display the current Drive, Track and Sector in

the LED Hex Displays.

Before adding the chips please re-read the section above about "Board

Height". Add a the chips with or without sockets (see above).

Be careful with the MN71A HEX displays -- the

pins are a little fragile.

Here is a picture of (a prototype version) of the board at this stage.

Finally you can add RTC Chip and 32.768 KHz Oscillator and coin battery

holder. One or two sizes can be used, but be sure to have the + terminal on

the RHS.

You can bring up the RTC menu from the main monitor, "Z" command, then "R".

The menu is fairly clear, but one unusual thing about this chip is you must

"Activate" it ("A" menu option) to start the clock the first time (even if

you set the time etc.)

Here is the RTC menu:

The board is now fully setup. What remains to be done is understand the

fairly extensive software menus and commands.

THE FPGA Z80 MONITOR COMMANDS

As described above the board can initialize in three completely different ways.

If Bit 7

& 0, (Pos1+8),

is closed, the Z80 reads (0xxxxxx0H) from

the IOBYTE port (46H)

and goes into its internal monitor mode. There is in fact no

connection

with the S100 bus. The only communication with the outside world is via

the USB port.

Normally one would not go to the

Z command but

would select one of the two "Drives" A or B.

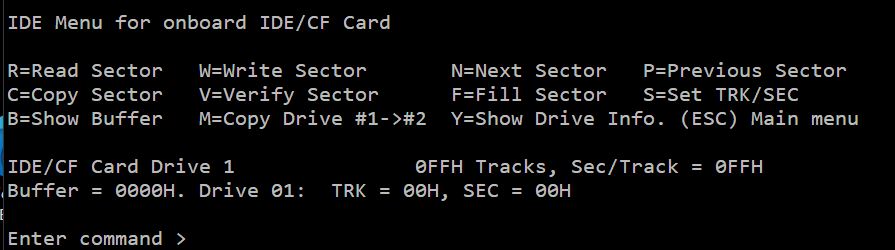

Here is the sub menu for the IDE drive:-

The "current sector" under consideration is always shown. In this case

Drive 1: Track 0, Sector 0.

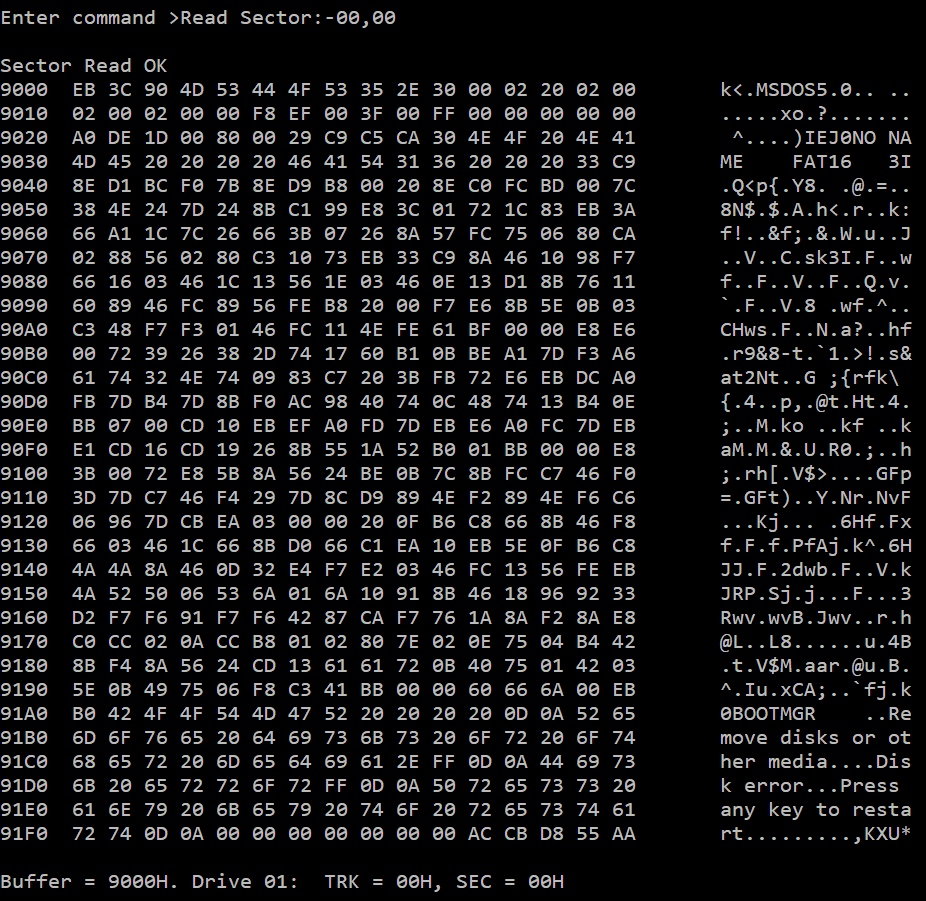

If we enter "R" we will display its contents (all 512 bytes):-

Most of the commands are self explanatory. The copy command copies the

current sector to another specified sector location on the same disk. The

verify command checks they are identical.

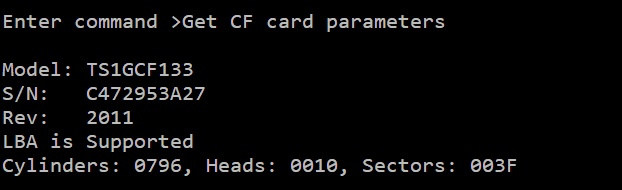

The

"Y" command

displays information about the "disk".

A few non-obvious shortcuts:-

If asked for a sector number, a CR will enter the current Track and , Sector.

All track, sector information are in hex values in the format xx,xx (+CR).

So a maximum of FFH,FFH tracks and sectors on a drive.

So a "R" command above followed by a CR will display the sector on Track 0,

Sector 0

The "R" with 12,34 then a CR will display the sector on Track 12, sector 34.

While we will see later when we operate from the S100 bus, in this "local"

mode you cannot move/view etc. sectors across drives.

To explore a different drive enter ESC and select from the menu another

drive.

THE S100 BUS INTERFACE

WITH THE FPGA_DC + IDE CIRCUIT

Having satisfied ourselves that we have the onboard hardware working

correctly we will now proceed to have the board interface with the S100 bus

as a true disk controller board.

That said, do not go to the S100 bus mode unless all the above commands work

flawlessly.

First we open

Bit 7, (Pos 1) of SW1. This dramatically

changes how the FPGA Z80 operates after reset. The FPGA_DC

IDE board now comes up

in normal work mode. Initially its Z80 scans the S100 input port waiting to

receive a "Handshake CMD".

This is a

21H byte sent out on

the S100 bus to output port (81H).

It responds by echoing this byte back on

the S100 bus input port 81H.

With this the S100 bus Disk Operating system BIOS knows the FPGA_DC board is

alive and well. The two then continuously interact with other via

series of single byte commands. Normally this is done in your

operating system BIOS.

This CMD driven approach was first used with our

ZFDC Floppy disk controller board now

some 10 years ago! It turned out to be very successful and reliable

allowing a very simple CPM BIOS to access 8", 5" and 3.5" floppies is over

50 different formats with a few very simple set of byte commands. I used

the same idea we have here, the boards local Z80 does all the dirty work of

finding a sector on a requested drive given just the track and sector

number. In order to simplify the BIOS

software with all 3 boards in this series of FPGA_DC boards will use the same CMD format.

We will just add a few extra commands not found on the original ZFDC board

commands.

Here are the main commands for this FPGA_DC board:-

CMD$SEL$DRIVE

EQU 5H ;**** (Re)select an already initialized drive

CMD$SET$SIDE

EQU 8H ;**** This will set the active side for a

floppy disk

CMD$SET$TRK$SEC

EQU 35H ;Set new current TRACK+SECTOR on current drive

(new)

CMD$READ$SECTOR

EQU 10H ;**** Read data from the CURRENT sector (on

current track, drive).

CMD$WRITE$SECTOR EQU

11H ;**** Write data to the CURRENT sector (on current

track, drive).

CMD$HANDSHAKE

EQU 21H ;**** Handshake command only sent during board

initialization/testing

CMD$SET$IDE$MODE EQU

38H ;Set IDE drive hardware mode on FPG_DC Board (Internal

or External)

; Second Byte 0 = External IDE mode + Interrupt

driven info (Default Mode).

; Second Byte 1 = External IDE mode + CMD driven

info

; Second Byte 2 = Local FPGA Board IDE mode + CMD

driven info

CMD$FAST$COPY$AB EQU

39H ;Special CMD to fast copy CF Card A:->B: (All within

FPGA_DC Board software)

CMD$SET$HOME

EQU 0AH ;This will set floppy disk head request to Track 0

of CURRENT floppy drive

CMD$GET$TRACK$ID EQU

0FH ;Read the CURRENT FLOPPY TRACK ID

CMD$STEP$IN

EQU 0BH ;Step head in one track of CURRENT floppy drive

CMD$STEP$OUT

EQU 0CH ;Step head out one track of CURRENT floppy drive

CMD$SEEK$NV

EQU 0DH ;Seek to track with NO verify of CURRENT floppy

drive

CMD$SEEK$TRACK

EQU 0EH ;Seek to track to (IY+DRIVE_TRACK) with the track

verify bit set on CURRENT drive/format

CMD$TRACK$DUMP

EQU 15H ;Dump complete CURRENT floppy track to S-100

system

INFO$READ$SECTOR EQU

42H ;Send info, read sector (Actual Sec Read done

externally)

INFO$WRITE$SECTOR EQU 43H

;Send info, write sector

CMD$FORMAT$DISK

EQU 44H ;Format the disk in the of the CURRENT drive

CMD$FDC$COPY

EQU 45H ;Fast Copy Disk C:->D:

CMD$GET$TIME

EQU 80H ;Get Time and Data from FPGA DC Board RTC

CMD$SET$TIME

EQU 81H ;Set Time and Data on FPGA DC Board RTC

CMD$BOARD$CONFIG EQU

82H ;Get FPGA_DC Board hardware configuration

; Bits 7&6 contain IDE & FDC circuit flags

; Bits 1&0 contain IDE Mode (0,1,2)

For a CPM (or MSDOS) BIOS only the 7 commands in yellow are needed. The rest

are extra for testing and diagnostic purposes.

That said the commands absolutely have to be bullet proof and 100% reliable.

The S100 bus OS BIOS does not know or care what type of disk is talking to.

It also has to be fast. There is a single 8 bit port bridge between the two

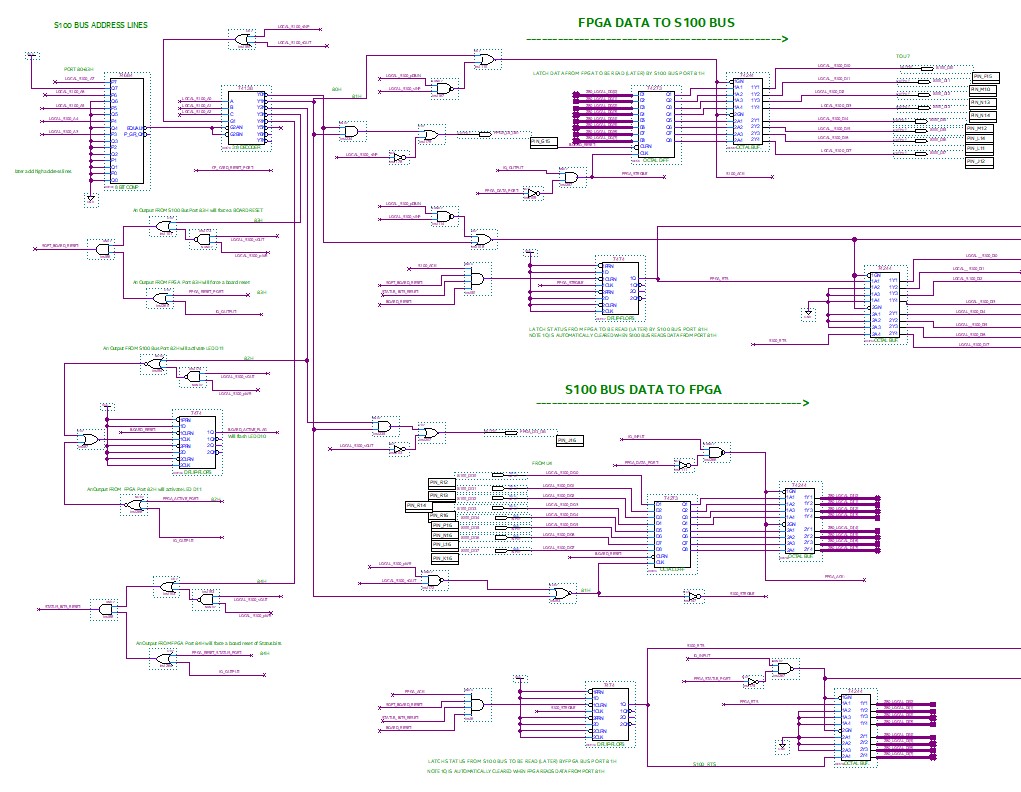

systems and a second status 2 bit port. The core of

FPGA_DC.BDR

circuit is shown here:-

While it is not necessary to understand this circuit to use the board you

might want to study it to get a feel how the board works. In essence

the FPGA Z80 just sits waiting for its port

80H (bit 0)

to get a CMD

byte (21H)

from the S100 bus. It reads the byte

automatically sending back to the S100 bus

port

80H

an acknowledge byte (21H)

that the data has

been read. The FPGA Z80 then processes further commands each time sending

a "CMD Complete" byte indicating the work is done.

Commands may have follow on bytes of data. For IDE/CF Card sector reads and writes for

example there

will be 512 of these. The S100 bus status ports (bits 0 & 7) on

both sides is port

81H.

While this sounds complicated in actual reality writing BIOS software is

very simple.

Further for debugging, as I mentioned above if we open

Bit 0, (Pos 8) of SW1 each and every command processed by the FPGA

Z80 will first be listed on the USB TTY output.

Here is a "breadcrumbs" trail of where we (start) copying CF card in drive

A: to B:

This brings us to the next part of the software -- the S100 Bus diagnostic

program.

The FPGA_DC+IDE Diagnostic Program

Before we take on the fairly complicate task of writing a full blown CPM3

BIOS to utilize this unique board it would be quite useful to have a S100

bus diagnostic program that sits in RAM at 100H upwards to test the board

interface. We essentially transplant the FPGA Z80 monitor disk

commands to the S100 bus. As we will see we elaborate on them to allow

multi disk transfers, reliability checks and anything else that assures us

the board can handle a CPM3 or MSDOS BIOS.

For debugging etc. I have written a Z80 program (IDE_DIAG.Z80)

that resides in the S100 bus RAM at 100H. It assumes the FPGA_DC ports

are 80H and

81H and the Console

IO is our

Propeller Console IO board (ports

0H

and

1H). Because it

resides at

100H it can be loaded

with CPM (later!), but for now you must download it from your PC via

a serial link and the Z80 Master monitor X command (X100).

By now this process should be familiar to most of our users. There are

other ways to do this, but in the end you need to have the

IDE_DIAG.COM (or

IDE_DIAG.HEX)

reside at 100H in RAM and jump to

100H from a Z80 S100

bus monitor.

First we open

Bit 7, (Pos 1) of SW1. This dramatically

changes how the FPGA Z80 operates after reset. The FPGA_DC

FDC board now comes up

in normal work mode. Initially its Z80 scans the S100 input port waiting to

receive a "Handshake CMD".

This is a

21H byte sent out on

the S100 bus to output port (81H).

It responds by echoing this byte back on

the S100 bus input port 21H.

With this the S100 bus Disk Operating system BIOS knows the FPGA_DC board is

alive and well. The two then continuously interact with other via

series of single byte commands. Normally this is done in your

operating system BIOS.

It will sign on as follows:-

After you select the drive you wish to work with the above menu will

appear.

As you can see this is a more elaborate version of the onboard FPGA monitor

commands.

Again most of these commands are self-evident. A number take one or more

follow-on single byte parameters. Some return to the S100 bus one or

more single byte values. In all cases they must return the

CMD_COMPLETE (F0H)

byte value confirming to the S100 bus BIOS that the requested operation

completed successfully. Anything else is regarded as an error and the BIOS

must act accordingly.

On the FPGA_DC Z80

monitor side the interpretation of these commands can be quite involved but

on the S100 bus side (all the user has to be concerned with in writing a

BIOS) it makes things very simple. In fact almost all the commands are one

of five commands:-

CMD_SEL_DRIVE EQU

5H ;**** (Re)select an already Initilized

drive

CMD_SET_TRACK EQU

7H ;**** This will set head request to a

specified track (ONLY)

CMD_SET_SECTOR EQU 9H

;**** This will set sector request to a specified sector (ONLY)

CMD_READ_SECTOR EQU 10H

;**** Read data from the CURRENT sector (on current track,(side),drive).

CMD_WRITE_SECTOR EQU 11H

;**** Write data to the CURRENT sector (on current track,(side),drive).

CMD_INIT_DRIVE

EQU 30H ;Select AND Initilized the current drive

All drives are always available. The default drive format for our IDE board is up to 0FFH

tracks, 0FFH sectors/track and 512 byte sectors.

These parameters can be

easily changed by a "Disk Parameter Table" at the end of the FPGA Z80

monitor code (or by setting bits 1 & 2

of the IOBYTE

switch, see below).

For those that have built and used the

ZFDC floppy disk controller board they will recognize this command

driven approach. However because CF and SD cards are quite

different the actual commands and the Disk Parameter Tables are different. The

FPGA Z80 IX register always points to the start of this table.

Here is the Disk Parameter table for an CF Card Drive:-

IDE_DRIVE_1:

DB CFCARD ;0H, (0FFH), DISK_TYPE (Default IDE Card/Drive)

DB 0FFH ;1H, Default Card Present

DB IDE_CS_1 ;2H, DRIVE_CS, actual Drive CS* Line

; Bits 0,1 are used for drive hardware selection (00=A, 01=B,10=C,11=D)

; Bit 2, 1 if side A is selected, 0 if Side B

; Bit 3, 0 if 8" disk, 1 = 5" disk

; Bit 4, 0 if Single Density, 1 = Double Density

; Bit 5 WD2793 INTRQ 1=ON, 0=OFF

; Bit 6 Write protect flag 0 = ON, 1 = OFF

; Bit 7 Drive Head load (currently unused)

DB 1 ;3H, Drive NUMBER

DB 0 ;4H, INITILIZED, uninitialized

DB 2 ;5H, 512 Bytes/sec flag

DB 0 ;6H, Tracks set aside for operating system (e.g. CPM 2 for floppies)

DB 0AH ;7H, HEX of Drive letter

DB 'A' ;8H, ACCII Character for Drive

DB 0 ;9H, First sector #

DW 512 ;0AH, <------ 512 Bytes/sec

DW 00FFH ;0CH, SECTORS PER TRACK:- (Was 3CH (60)for my on old CPM3 for Kingston CF 8G). (Note. No +1 for cards)

DW 00FFH ;0EH, Max Tracks

DW 0000H ;10H, TRK, Current Track

DW 0000H ;12H, SEC, Current Sector

DB 0H ;14H, Side

DB 0 ;15H, Formatting (Not used for SD/CF cards)

DB 0 ;16H, GAP1 ""

DB 0 ;17H, GAP2 ""

DB 0 ;18H, GAP3 ""

DB 0 ;19H, GAP4 ""

DB 0 ;1AH, GAP4R ""

DB 0 ;1BH, GAP fill byte

DB 0E5H ;1CH, CPM Sector data fill byte

DB 0 ;1DH, Special Flag

DB 0000H ;1EH, Skew Table (Not used for SD/CF cards)

DB 0 ;20H, Format Number

DW 0000H ;21H, Track Size

DB 0 ;23H, Number of (Floppy) disk sides (Not used for SD/CF cards)

DB ' IDE/CF/SD Card A: ',0 ;24H

So the value of Bytes/Sector would be

(IX+SEC_SIZE_BYTES), where

SEC_SIZE_BYTES = 0AH.

The advantage of this command driven approach is that the current S100 bus

CPU does not have to go into DMA mode or sync the bus with wait states when

reading or writing sectors. Any of our S100Computers CPU boards, in

fact in theory, any manufactured CPU board, should work in this system.

The downside is that disk access is a little slower. Not as slow as

you might think however because while the requested sector parameters are

passed back and forth with above commands and handshaking, the actual

512 bytes of data transfer across as a block over the connecting bridge

port one byte immediately after the other using the Z80 block IO

instruction. Normally you will notice no

difference with say a few sectors moved with CPM or even MSDOS.

However a total disk copy from one drive to another will be slower. The

monitor in fact has a special disk copy command to help with this (CMD_DRIVE_COPY

EQU 43H)

a little. Remember these CF and SD cards have an enormous capacity --

way outside early days CPM or MSDOS. Copying the first few "tracks"

usually is all that is required.

For those that wish to play around with the software there is 512K of RAM

available to the Z80 FPGA. Some fancy sector caching routines could be

implemented. Also for MSDOS, multiple sectors could be written

or read with a single command. If you develop code improvements please

let me know.

The Real Time Clock (RTC).

All 3 boards have a DS1305 RTC

chip. This is one example where using a FPGA really shines. With

its 3 wire SPI connection to the FPGA with one chip you get a complete

RTC read and write circuit. Whole S100 boards in the past were

required for this function. The Calendar/Time settings can be set

within the Z80 Monitor or from the above FPGA S100 Bus diagnostic program

(see below). The circuit and software is identical for all three

boards. The chip defaults to 24 hour format. You must have the

coin battery present and you must use the Monitor to initialize the chip for

the very first time (Monitor B, CMDs).

Here is a picture of the interface using the FPGA S100 Bus diagnostic

program:-

The data returned to the S100 Bus with the 81H Command is in the format of

the following 14 character string:-

20210722131004

All ASCII characters. The format is 24 hours.

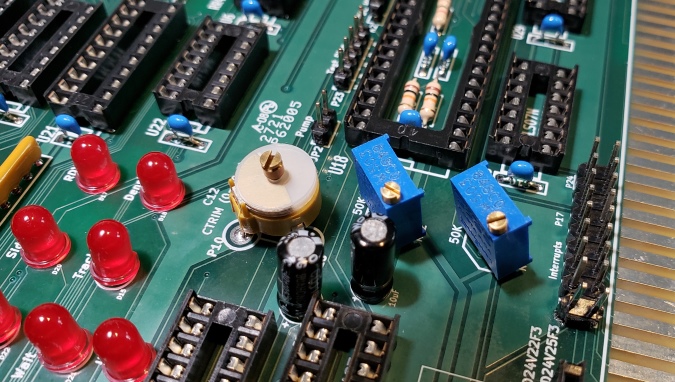

FPGA_DC + FDC Board.

This board has much in common with the above FPGA_DC+IDE Board.

Instead of an 8255A and two IDE sockets we have a Western Digital 2793

Floppy Disk controller and two ribbon cable connectors along the top of the

board to hook-up floppy disks.

The build instructions are exactly the same as is the software. The

main difference is the replacement of the 8255A with the WD2793 chip.

Study this chips circuitry carefully in the schematic. Critical are the two

0-50K Ohms Pots (RV1 and RV2)

and the 0-50pF Cap C12. Solder these carefully to the board taking care to

place them in their correct orientations for the center tap. We will

adjust them later.

Note the Diode D14 should be at least a IN4005 1Amp diode. It's there

to reduce the voltage going to the HEX displays so they don't run too hot.

As for the IDE board you need to decide if you will use the 20 Pin DIP or

SMD version of the RTC chip (U13).

| |

|

Solder in all the sockets, jumpers, resistors, caps and the 50 and 34 pin

connectors P9 and P1.

Be sure the Pololu 5V and 3.3V regulators are the

correct types and deliver the

correct voltages to the WaveShare FPGA adaptor before inserting it.

Please note Pololu has come out with more 5V and 3.3v regulators.

Please examine the pinouts and match them with the board sockets.

Unfortunately the newer 5V and 3.3V units look exactly the same on the

surface. Presumably some of the internal resistors are different to give 5V

and 3.3V.

Here is a picture of the (prototype) board at this stage:

| |

|

Next solder directly to the board the three 74LVC245s U10, U15 and U16.

If possible use known working chips you don't want to remove a faulty one

later.

Carefully insert the WaveShare

Cyclone IV adaptor in its sockets. Power on the computer.

"Virgin" Cyclone IV Adaptor boards from WaveShare may have a FPGA

preloaded with a program (in the

EPCS16 Flash RAM) that already that pulses its

4 onboard LEDs. Previously programmed by you FPGA boards of course will

not.

In any event open the Quartus FPGA_DC project folder (the expanded

FPGA_DC.ZIP download, see bottom of this

page) and program the FPGA using the FPGA_DC.bdf

file.

Now would be a good time also to study in detail the

FPGA_DC.bdf file to

understand how the board "works". Remember the FPGA utilized its own

internal 30-40 MHz Z80 and so utilizes a .HEX file for its ROM code. This

.HEX file resides in the FPGA_DC\ROM_HEX_FILES sub-folder. The source for

this file is FPGA_DC.Z80. You don't need to alter this file for

normal use but its also provide in case you need to.

Should you wish to "play around" with this file, I supply it and its

components in the folder

FPGA_Disk_Controller Board where

it can be assembled on a

PC using Altair.com etc.

Be sure to move the final FPGA_DC.HEX file to the Quartus FPGA_DC\ROM HEX FILES

folder when done as Quartus is counting on finding the

FPGA_DC.HEX file there (or readjust the ROM Module Properties in

the .bdf file)

If you program the onboard Cyclone IV FPGA at this point nothing will happen

except the LED D10

(Board Active) LED will pulse. This must happen. Do not go further

unless it does.

LEDs L1 and L2 on the WaveShare FPGA board will also light up - this is

normal (it depends on how they were programed in the .brd file).

Next install the following IC's:-

U2, U4, U7 and the RAM chip U5. (U10 is already installed).

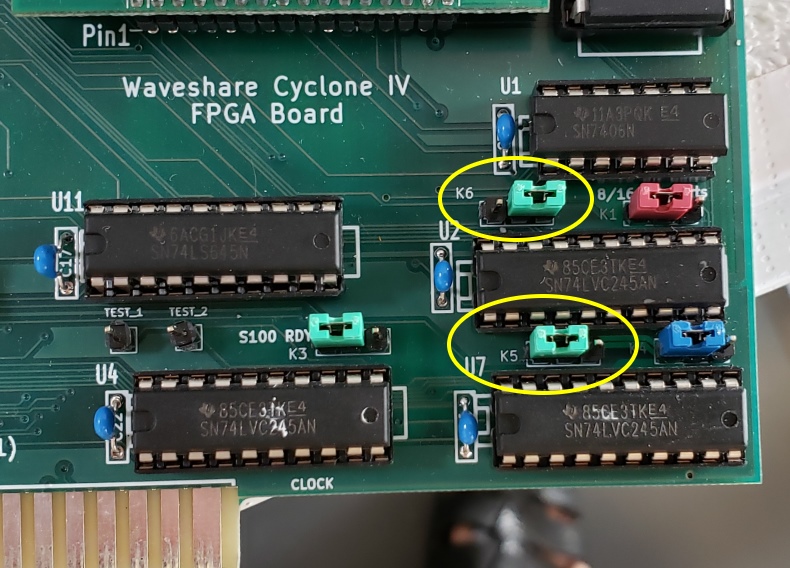

To activate the FDC Card circuit within the FPGA jumper K6 2-3 and K5

1-2. Note it's very important you get these two jumpers

correct.

IEEE-696 16 bit S100 bus port IO addressing is assumed (the upper 8 lines

being zero) for this board. This can be easily bypassed within the FPGA

(Jumper K1 1-2). Do so if your CPU board does not zero the high

address lines for port I/O. To be safe we will jumper K1 1-2 for now.

Note 16 bit CPU's will probably require K1 2-3.

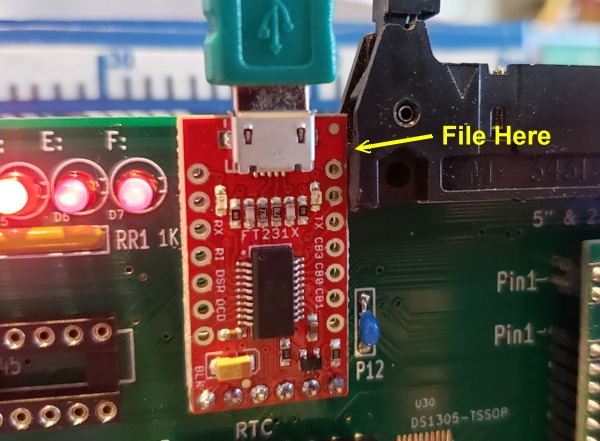

Install the Sparkfun

FT231x USB adaptor. Note the Sparkfun 231x board

(current part number BOB-13263) is designed to be compatible with both 3.3 V

and 5V (TTL) logic circuitry. The “jumper” on the back of the board is only

used to select whether 3.3V or 5V (derived from power supplied by the USB

cable) is provided to the board’s Vout pin.

Since the FPGA floppy controller board does not make use

of this Vout pin – it is a “no connect".

You can

solder the adaptor directly to the board or use sockets. See the

section above on soldering sockets. I suggest direct

soldering. Note the USB FT231x adaptor actually has 3 sockets. The two side ones are not used here and are

only there to steady the adaptor on the board. I use only pin 1 in each

case. You can also use the

Adafruit CP2104 USB adaptor equivalent adaptor.

Note if you use a ribbon cable socket with ejectors (recommended), the

spacing on the LHS of the socket is very close to the USB adaptor.

I filed a little of the plastic from the side of the socket for a

better fit.

The Sparkfun adaptor fits better than the Adafruit adaptor BTW.

The default software on this board assumes a USB port running at 38,400 BAUD, 2 stop bits, no parity.

(This can be changed within the FPGA_DC.bdf file). There are a number

of Windows/PC programs you can use to receive and display the data. I

like

Absolute Telnet

from Celestial Software, but others such as

puTTY and

TeraTerm are free.

The board has an "IOBYTE" switch (SW1),

which defines what the FPGA_DC Z80 monitor

does on power up. The default mode, all switches open, (no switch) causes

the Z80 monitor to get

0FFH

from port

46H after a reset. This is the boards normal mode of

operation but we will not use it yet. Currently only two

switches are utilized:-

Bit 0 (Pos

8), (Reading left to right), when closed, (xxxxxxx0H),

this causes the board to send status information to the USB port during

every step of its operation. A remote PC can thus watch how commands sent

from the S100 bus are operating during "disk" operations. This slows down

the Operating System BIOS a little but is invaluable for debugging etc. When

open no commands are sent.

Bit 7, (Pos1),

when closed, (0xxxxxxxH),

this causes the board upon reset to bypass the S100 interface and go

directly to its onboard monitor. The onboard monitor contains all the

"normal" commands for a Z80 CPU, display/change RAM, ports etc. but it also

contains two very special command I

and

U.

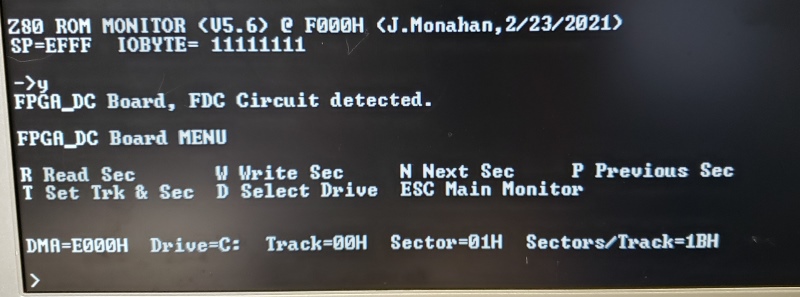

Place the board in the S100 bus with

SW1 positions

8

and

1

closed. Power up and again load the

FPGA_DC.BDF

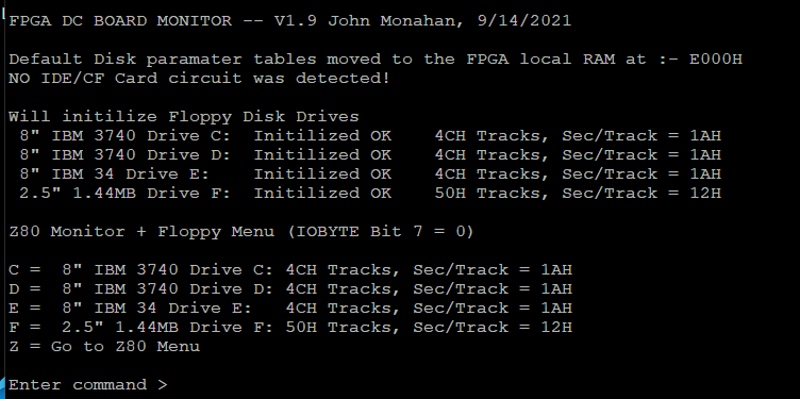

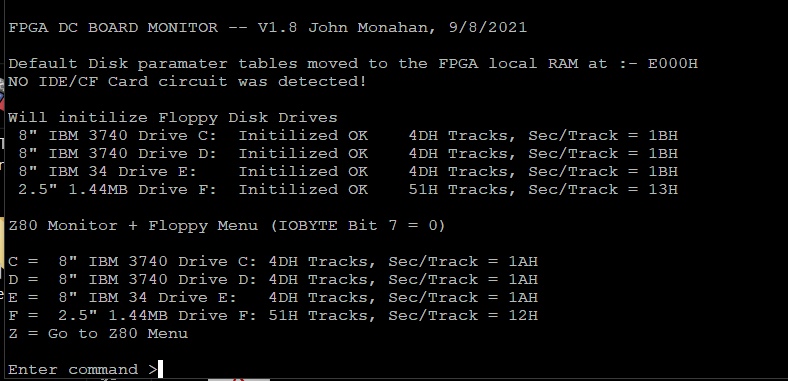

file into the FPGA. Upon reset the FPGA will boot up its Z80 monitor.

You

should see the following display:-

As for the

FPGA_DC IDE board first utilize the Z command to checkout the

"standard" Z80 commands.

They must work correctly before going

further.

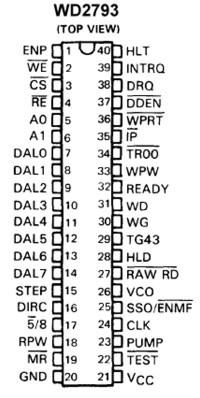

WD2793 Hardware

Like the earlier 1791/1795 chips the

WD2793 consists of a 40 pin chip with many of the same data and control lines as

the earlier 179x

series. In order to fully understand their function you should read the detailed

description of how the WD2793 FDC chip works.

The complete data sheet can be seen

here.

You should read this data sheet in detail to understand much of what I

have below.

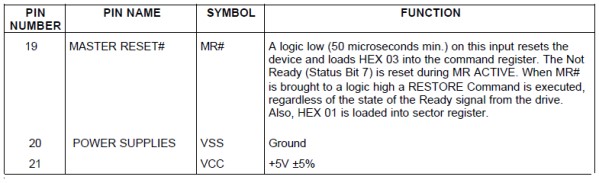

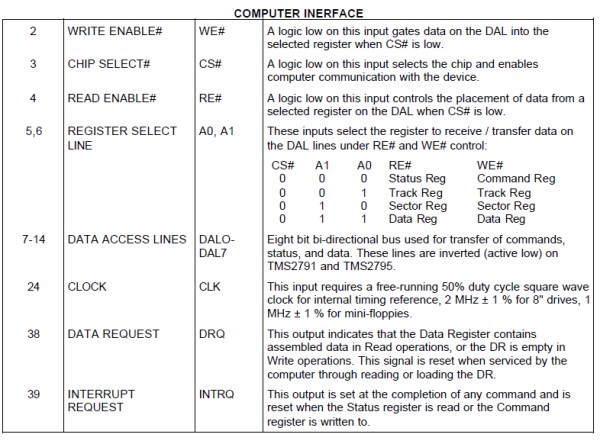

Let us first look briefly at the function of the 40 pins:-

Most of the pins are fairly straightforward and should need no further

discussion. Pins #26 and #33 as we shall see, do need to be adjusted, but

Western Digital (by this stage) made it easy to do with a special test pin

(#22). The one complication in any system is if you intend to use the chip

with both 8" and 5" drives mixed together. Because the data rate of a 5"

drive is half that of an 8" drive the clock frequency has to be divided in two.

Pin #25 is set aside for this use.

One very important control pin is INTRQ (#39). This pin pulses high (very

briefly) when every a command is completed. We will gate the output of this pin

going to the NMI pin of the Z80 such that (if desired) the FPGA Z80 will experience a

NMI interrupt whenever the WD2793 completes its current command (seek, read a

sector, format a track etc.). This is a very convenient and efficient way to

synchronize the two chips and make sure the system does not "hang" with for

example a false disk command or data.

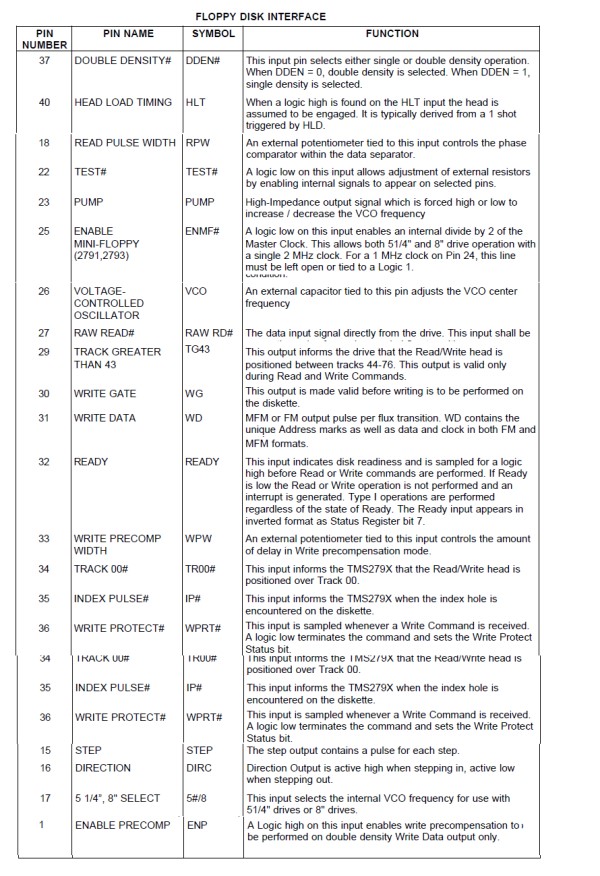

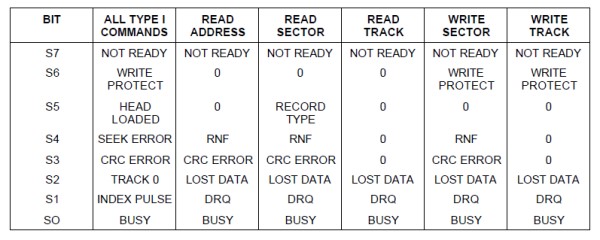

WD2793 Software

All Western Digital FDC chips have at

their base port a key "status" port that continuously displays important

information about the chips actions and results. This is reflected in a

series of bit flags. The actual meaning of these bits changes depending on what

the chip has being doing. Here is a summary of the bit flags for the most

common uses:-

The challenge with any disk controller is matching the data rate of the stream

of data bits coming in from the disk surface with the capability of a CPU's

ability to place the corresponding bytes in memory AND at the same time decide

when the job is done. In the early S-100 days when only 4MHz Z80's were

available, the Z80 simply could not keep up. In other words the Z80 was not

fast enough to continuously monitor the status register status bits AND at the

same time take data from the data port and place it in RAM -- particularly

in double density modes. Two basic ways around this were used. One was to

use a dedicated DMA controller on board (which was fast enough) -- but this

sometimes caused conflicts with other (pre-IEEE 696) S-100 boards. The

other simply took account of the fact that IF there are no errors, one knows

exactly how many bytes to expect (or send) and you can lock the data rate of the

FDC to that of the Z80 utilizing the Z80's block I/O instructions by inserting

CPU wait states during each bytes transfer at the same time counting the

total number of bytes processed.

Fortunately utilizing our 40MHz FPGA Z80 we don't have to use these

round about approaches. The Z80 can simply input individual disk bytes AND

at the same time look at the WD2793 status port to see when the next byte is

available (bit 1, the DRQ bit goes high). That said things are still very

tight. You really have to watch your clock cycles. To input a sector

here is the key code I use:-

READ_SECTOR:

LD

DE,Sector_Size

LD HL,DMA_Address

LD C,Data_Port

CHK_STAT:

IN A,(WD2793_Status)

RRA

RRA

JR NC,CHK_STAT

;Very fast way to check the DRQ status bit

IN A,(C) ;Very

fast way to input data from [C] port

LD (HL),A

DEC DE

LD A,E

OR A,D

JR NZ,CHK_STAT

Using this very efficient code a 40 MHz Z80 is able to keep its head above water!

Interestingly using the special Z80 INI instruction did not work with the

circuit on this board. It's unclear to me why. Even with the above code the

FPGA Z80 clock needs to be 40 MHz. A faster CPU makes no difference

and indeed may be unreliable since you are way outside the specs of the WD2793

chip. Code like this in fact can be utilized to read or deposit a whole

track on a disk.

All of the above is perfectly fine so long as there are no errors. However if

for some reason the WD2793 comes up short in getting bytes from a sector (a

wrong formatted disk was used for example), the system will hang. There is

not enough time to incorporate a software timeout counter in the loop.

What could be done is setup a watchdog timer

in the FPGA such that, IF, a

sector is not read before the timer times out, it triggers a NMI interrupt on

the Z80 which then causes the Z80 to brake out of the above loop and act

accordingly. If the sector is read/written properly in time it turns off the

watchdog timer. I have not incorporated this option yet!

That said the above arrangement makes for a very reliable WD2793 arrangement to seek,

read/write sectors or tracks etc. There are no wait states, no DMA

controllers or inserted HALT opcodes.

WD2793 Commands

Exactly like the earlier 1791/1795 chips the WD2793 contains five 8 bit

registers which completely control all the chips functions. They are:-

Data Register.

This is the register to/from which sector byte by byte data is obtained.

Track Register. The require disk track

is placed in this register. Upon a track seek (with verify) the new track can be read from here

Sector Register. The require sector to be read/written

to is placed in this register.

Command Register This is the most important register it determines what next

the chip will do.

Status Register This register

contains various flag bits to describe command success or errors.

Tracks on a disk are laid down in the format:-

Track header...gap...(Track/Sector ID..gap..Data..gap) x N

times, ...End of Track

The Track/Sector ID consists of 6 bytes:-

Track#, Side (0 or 1), Sector#, Sector Size flag (,1,2,3

or 4) , and a 2 byte CRC check.

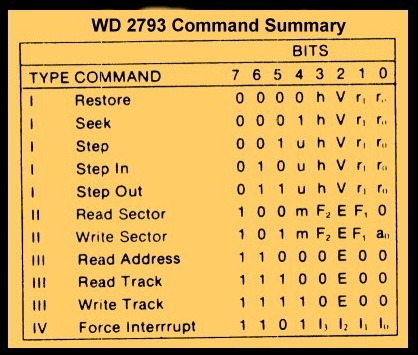

The command register accepts 11 different commands with very

precise bit patterns. They are summarized in this table.

First you will notice that the commands

are grouped into 4 groups.

The Type I commands

control the head movement. Bits 0 and 1 determine

how fast the head will move from track to track. For most modern drives the maximum

speed so these bits are 0,0. The V bit determines if the chip will verify

if it is on the correct track after the head to track movement is complete. Normally

a 1 but for disk formatting it is set to 0. The h bit determines if the head is

to be lowered on to the disk before or after the command function is complete.

The

Type II commands are clearly the most important (but the most complex).

Bit 0 of a Write sector 'a0' has to do with disk formatting and need not concern

us here and is set to 0.

F1 is another story. This bit simply determines if the chip is to check if the active head is reading

from the requested side of the disk. If 0 the WD2793 chip skips this side check. If

1 it checks that the active head is really on the requested side. The side of the

disk is contained in the Track/Sector ID field. The second byte of this field is

0 for side A (or a single sided disk). It is 1 for side B.

The E bit determines if there is to

be a slight time delay (15 ms) in setting the chip's busy flag after lowering the

head.

F2 on a WD2793 chip is relevant if F1

was set to 1 (enable side compare). If it is 0 the sector side field must

also be 0 (Side A). If it is 1 then the sector side field must also be 1 (Side B).

Finally the m bit allows you to read/write contiguous sectors on a track.

Very fast, but unfortunately difficult to incorporate in CPM BIOS code

because multiple sectors often are on different tracks.

The

Type III command either reads the

above track/sector ID field or a whole track. The write track command is primarily

for disk formatting.

The

Type IV command, force interrupt command

is to pull the chip out of a lockup situation. It's basically a chip reset command.

Use the Z command to bring up the monitor and

then use the

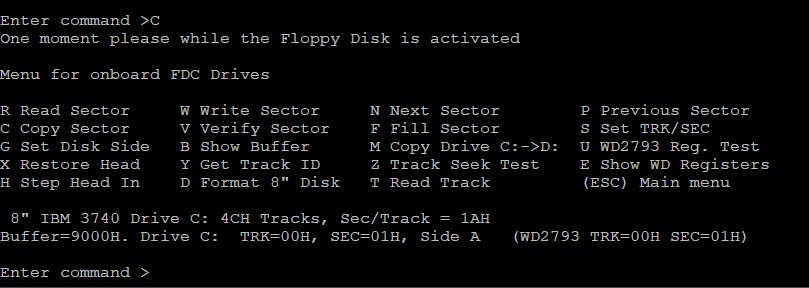

U command to bring up the Floppy disk menu.

(Please allow a second or two for the disk to come on).

It is this sub menu we will concentrate on for this board.

Let us go through the commands one at a time.

First add U3, U23, U6, U11 (a 74LS645), U21, U14, U12 (a 74LS645), U9 and

U20.

Add U19, U22, U17, U26, U25, U29, U28, U22, U1.

Add U8 and U13 (the DS1305 RTC Chip).

You can also add the four HEX displays.

Finally add the WD 2793 FDC chip U18.

At this point all IC sockets on the board should be full.

We will start calibration and

testing of this board by connecting a single 8” floppy drive, configured

as “Drive A”.

You also require an IBM

formatted single density floppy disk to perform these tests.

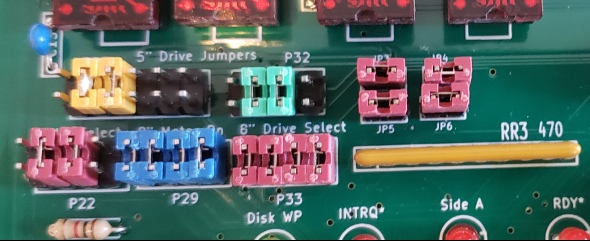

The following jumper settings

are for a pair of 8” drives (A: and B: ) and a 3.5” drive (C: ). These

settings will also work for testing with a single 8” drive attached:

P22: jumper pins 3-4, and 5-6

P29: no jumpers (Actully

does not matter).

Your 8” floppy drive should be

configured for stepper motor (spindle motor) “on” with “head load”. See

your floppy drive manual for setting this option on the drive.

P33: jumper 1-2, 3-4, 5-6, and

7-8. This allows the board to drive all 4 “drive select” lines to the

floppy drive cable.

JP3, JP4, JP5, JP6: These

jumpers force an active floppy drive “Ready” signal when the

corresponding drive has been selected. This is not necessary for normal

8” drive operation.

These jumpers are only necessary

for 5.25” or 3.5” drives that use pin 34 for a “disk change” instead of

a “ready” signal. However, in most cases putting a jumper on all 4 will

work fine.

P28: jumper 3-4 and 5-6. These

jumpers select the signals to 5.25”/ 3.5” drive pins 2 (“density

select”) and 4 (“in use”)

P32: jumper 3-4 and 5-6. These

jumpers allow use of a 5.25”/3.5” drive configured for use with a PC,

connected to a standard PC floppy drive cable.

K3 and P25: jumper K3 1-2 and

jumper P25. These selections drive the S100 “Ready” bus signal, which is

required by the IDE board but is not necessary for the floppy controller

board.

P20: these jumpers select signals to drive pins 48 and 50 on some very

old 8” floppy drive models. They are rarely required – consult the board

schematic if your drive requires these signals.

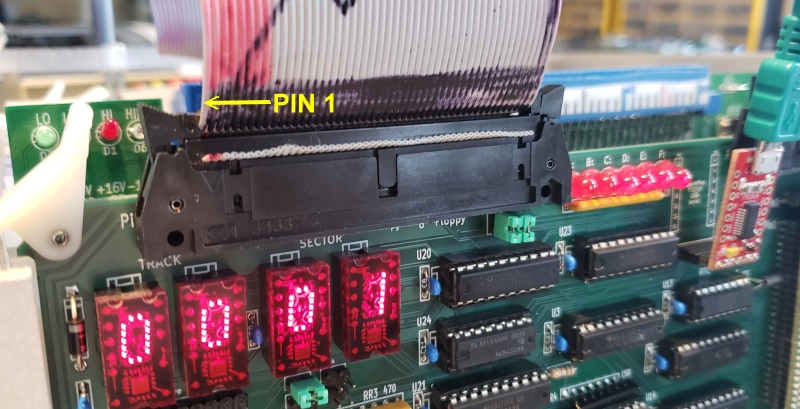

Hookup your 8" Floppy disk ribbon cable. Be sure you have the cable

correct. All signals are on the P9 connector even pins (top row). All

ground pins are on the odd pins.

Here is a close-up picture:-

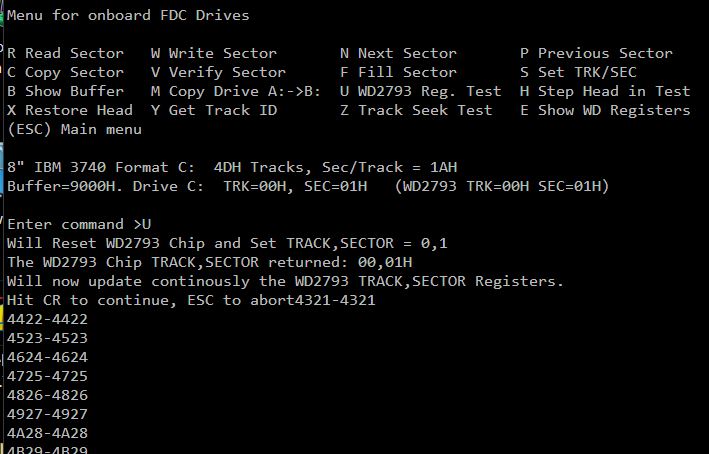

The first thing we will do is check the WD2793 itself is receiving data from the

FPGA. With the "U" test we will continuously send Track and sector

data to the chips Track and Sector registers (Ports F1 & F2). We will read

them back. They must be the same. Here is an example:-

| |

|

Next we will "Restore" the drive head to Track 0 (X

CMD). The Track 0 LED D15 should light up.

Then use the "H"

command to step the head in one track. Each time you press "H" you should

hear the head move. The Track 0 LED D15 should be off. The "X"

command will restore the head back to track 0 and the Track 0 LED should

come back on. This is a very simple test but it must work. It is completely

independent of the read/write drive electronics. Do not waste time going

further until you get this working. BTW, whenever the disk is rotating

the IP LED (D16), should be faintly flashing. The Head Load LED

(D19) should light up also. For 8" Single Density Disks LED D18 should

not light up and the Side A LED D20 should be on and the 8" Disk LED D12

should be on.

Note also that LEDs D2 and D3 are RFU (so they will not

light up) however D4, D5, D6, and D7 will normally all light up.

Next we need to do actual disk sector reads and writes. Before doing this

however the

internal WD 2793 chip data separator needs to be fine tuned.

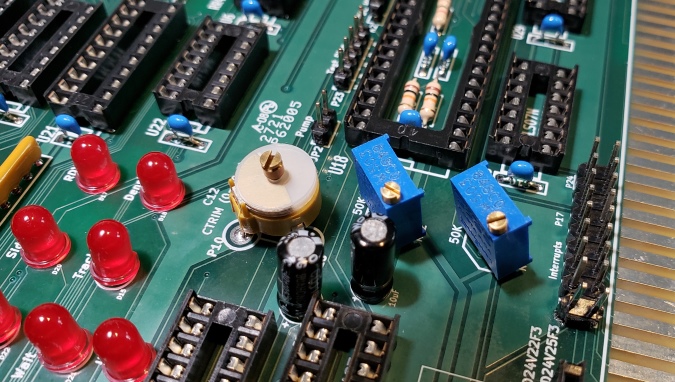

Adjusting the Data Separator setting of the WD2793.

One thing that often scares people away from these early FDC chips is the

need to fine tune the data separator/analogue signal of the raw data coming

in from the disk. I have found that the WD2793 works with almost

any setting for 8" single density drives. Not so for the double density 5"

floppy disks however. Early FDC boards often had elaborate hardware

that sometimes required careful adjustment to get a reliable signal,

particularly for Double Density modes. Western Digital greatly

simplified this process with the WD2793 chip. All that is required is one

50K Potentiometer and a 5-50pF variable capacitor. The

adjustment process is as follows:-

Reset the WD2793 chip (Reset on the S-100 system).

Start the boards Z80 Monitor program Z command.

Output

40H to Port

F5H.

Use

QOF5,40. This will set the WD2793

chip to double density mode, 8" disk. The LEDs D18 and D12 should be

on, (the others don't matter).

This should set the WD2793 pin 37 low and its pin 17 high.

Then

Jumper JP1. This sets the WD2793 "TEST" pin (pin 22) to ground. (It

will not work if JP1 is installed before the above reset).

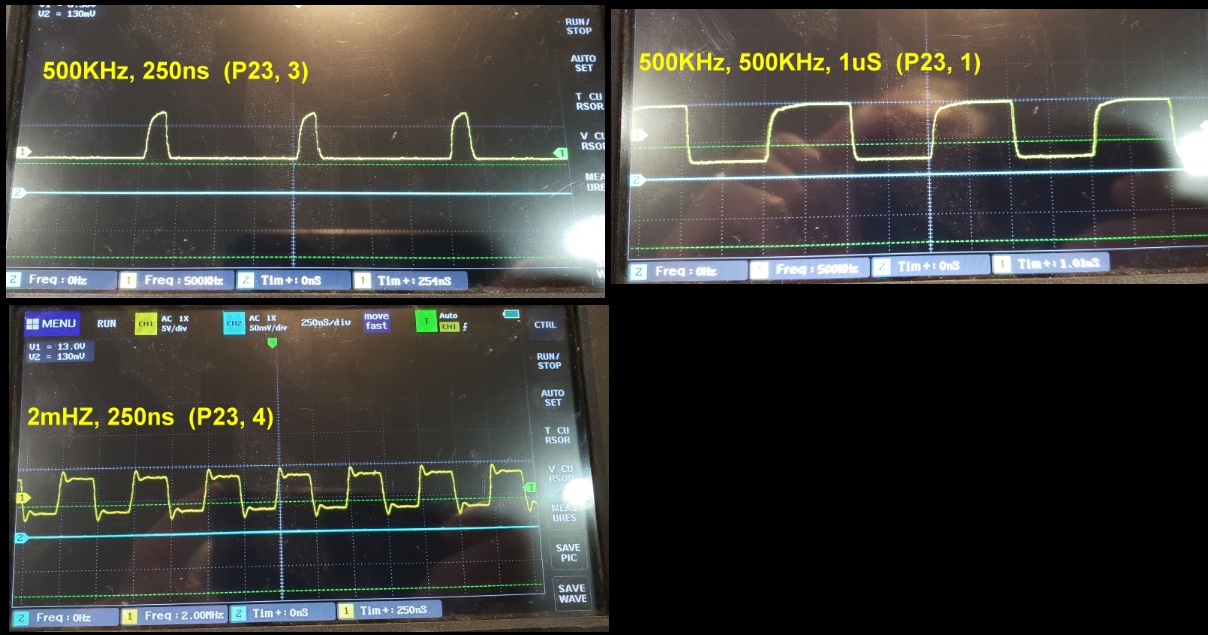

Then with a scope or logic analyzer observe the continuous

2mHz pulse on pin

24 of U18, or P23, pin 4.

Adjust the 50K pot on pin 18 (RV1) so the signal on U18 pin 29 or

P23 pin 3 has a width of

250ns.

Next adjust the variable capacitor (C12) so that U18 pin 16 (DIRC), or

P25, pin 1 has a width of

1uS

You

can use a scope, digital analyzer of simple handheld frequency counter.

When done be sure to remove the jumper on pin 22 JP1.

The

"Write Precomp Width" control Pin 33, does not seem to be critical.

I leave RV2 at about 25 KOhms. Try adjusting it if you get a lot or reseeks

while reading double density disks.

The above sounds more complicated than it actually is. In fact I have found

if the pot and cap are roughly in the middle of their range the chip works

fairly reliable. A poor man's approach might be to do continuous disk sector

reads and adjust things on the fly!

Below are pictures of my adjusted board using a

YEAPOOK ADS1013D digital storage analyzer. (An excellent machine BTW,

reasonably priced.)

When you are satisfied with the above settings, reboot your system

(remember to remove the JP1).

The following instructions require you have an 8”

IBM-format single-density disk inserted in the drive.

In the default mode the FDC menu comes

up with floppies B: & C: as 8" Single Density Single Sided disks.

Use the

"X"

Command to restore the head to track 0.

Use the

"H"

Command to step the head in one 1 track.

Then use the

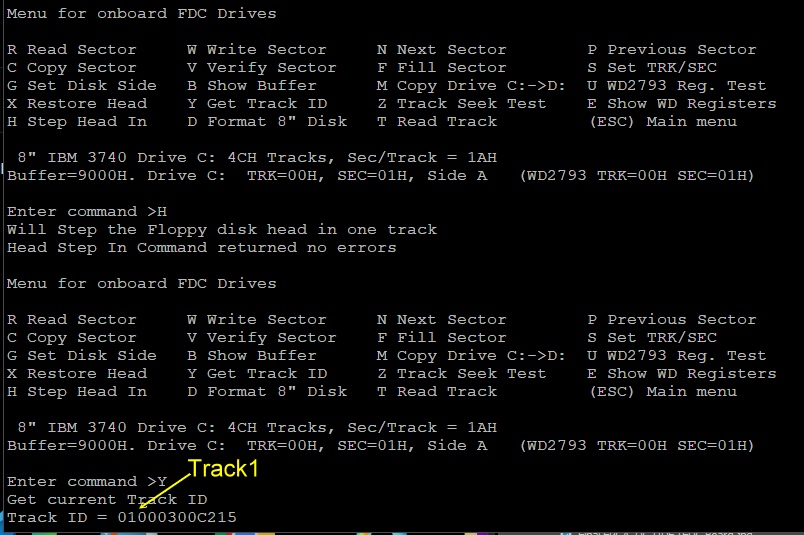

"Y"

Command (Get Track ID) to have the WD2793 read the "Track ID".

This is

a very important test. It reads from the disk 6 bytes into RAM the "ID" of a

track. It can be any sector but it must be the correct track (01 in

this case)

Here is an example:

The format is:-

The first byte must be the correct track number. 01H in this case.

It is absolutely essential you get the

"Y"

command working before going father. It utilizes almost all the functions of

the WD2793 chip circuit.

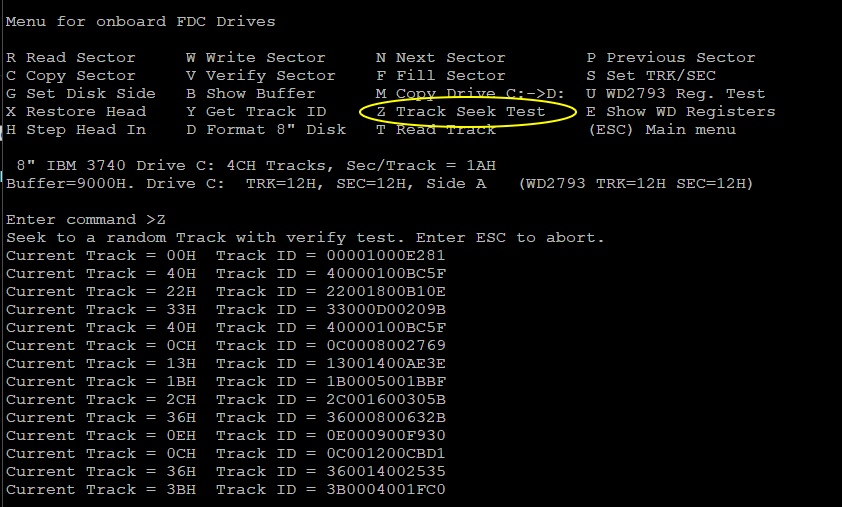

You can then move on to the "Z" Command that randomly seeks to different

disk track and reads the track ID.

The "Current Track" in the WD2793 register should always match the first

byte of the Track ID.

Here again is an example:-

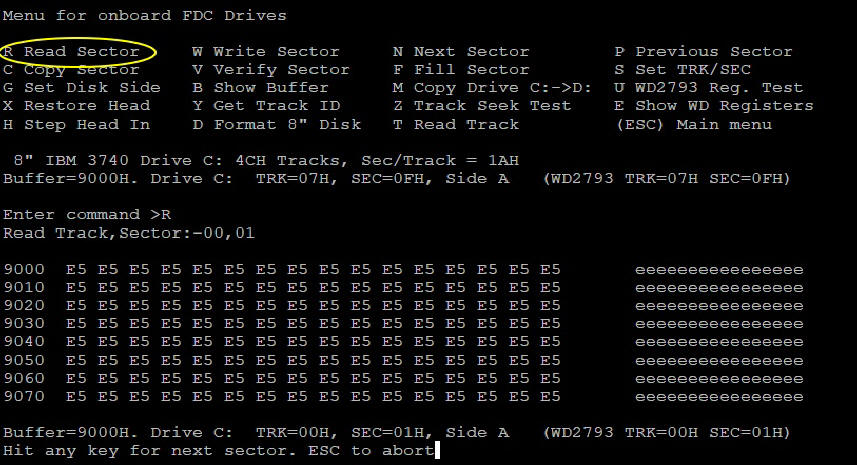

Next we will do an actual read sector. Start with Track 0, Sector 1, (There

are no 0 sectors on floppies). You should see something like this -- again

with no errors.

Hitting a CR will show the next sector. An ESC will drop you back to the

floppy menu. This test does require a properly formatted floppy disk!

The rest of the menu items are hopefully obvious.

If you have added the HEX LED displays they should be continuously updated

BTW.

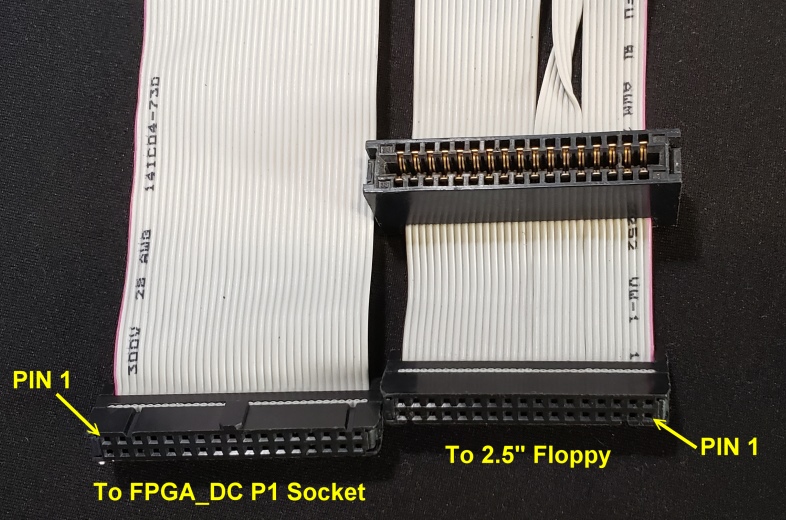

The board will also accommodate 5" and 3.5" Floppy disks. They connect

via a ribbon cable to the connector P1.

Lets use a 3.5" drive. It's the most reliable and still reasonable common

these days.

You can format these disks on an old MSDOS PC. As far as the

WD2793 chip is concerned the format is an 8" drive,

Double Density, 80 (50H) tracks, 18 (12H) 512 byte sectors/track.

BTW, the Format command is also supplied in the

FDC_DIAG.COM program

(see below) and will also format these disks correctly with this board.

Making up a cable to these drives can be tricky/frustrating. I use the

common IBM-PC "twisted" floppy cable. Unfortunately you will probably have to

modify most that come with motherboards because they have a blocked pin hole

in the (motherboard) socket to prevent users putting them in the wrong way.

Here is a picture of the one I made up from a PC floppy cable.

Check Pin 1 as shown is connected at both ends. Note the cable wraps

around the top of each socket with a clamp to hold it in place. The

center notch for the FPGA socket must be as shown.

Likewise jumpers on the board for 5" and 3.5" drives can be tricky. On

the drive, set it as drive A:

Here are the board jumpers for 8" floppies and a TEAC 3.5" drive in C:

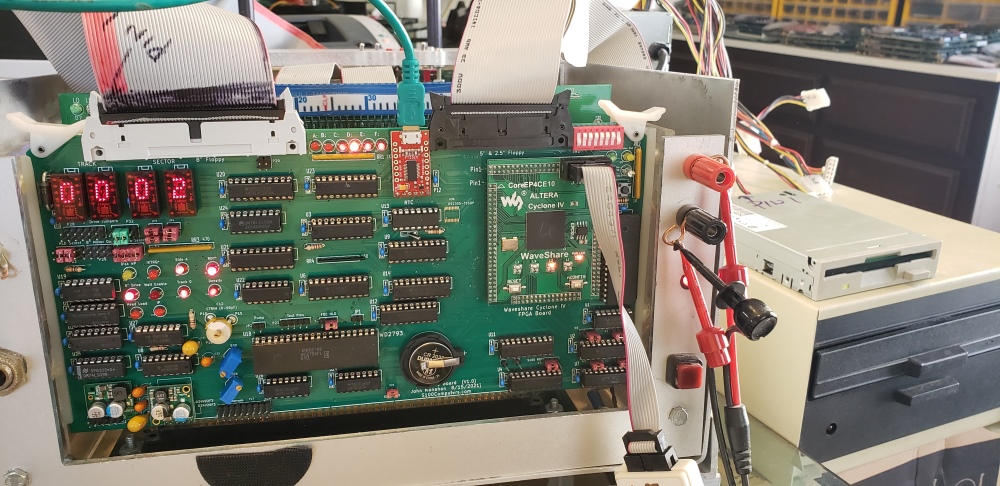

It looks somewhat messy in my S100 bus test system but here is the floppy

setup.

THE S100 BUS INTERFACE WITH THE FPGA_DC+FDC CIRCUIT

Having satisfied ourselves that we have the onboard hardware working

correctly we will now proceed to have the board interface with the S100 bus

as a true disk controller board.

That said, do not go to the S100 bus mode unless all the above commands work

flawlessly.

We essentially transplant the FPGA Z80 monitor disk