I went to see my friend here to make these boards.

He took a quick look at it and had me change some minor things and taught me a little more.

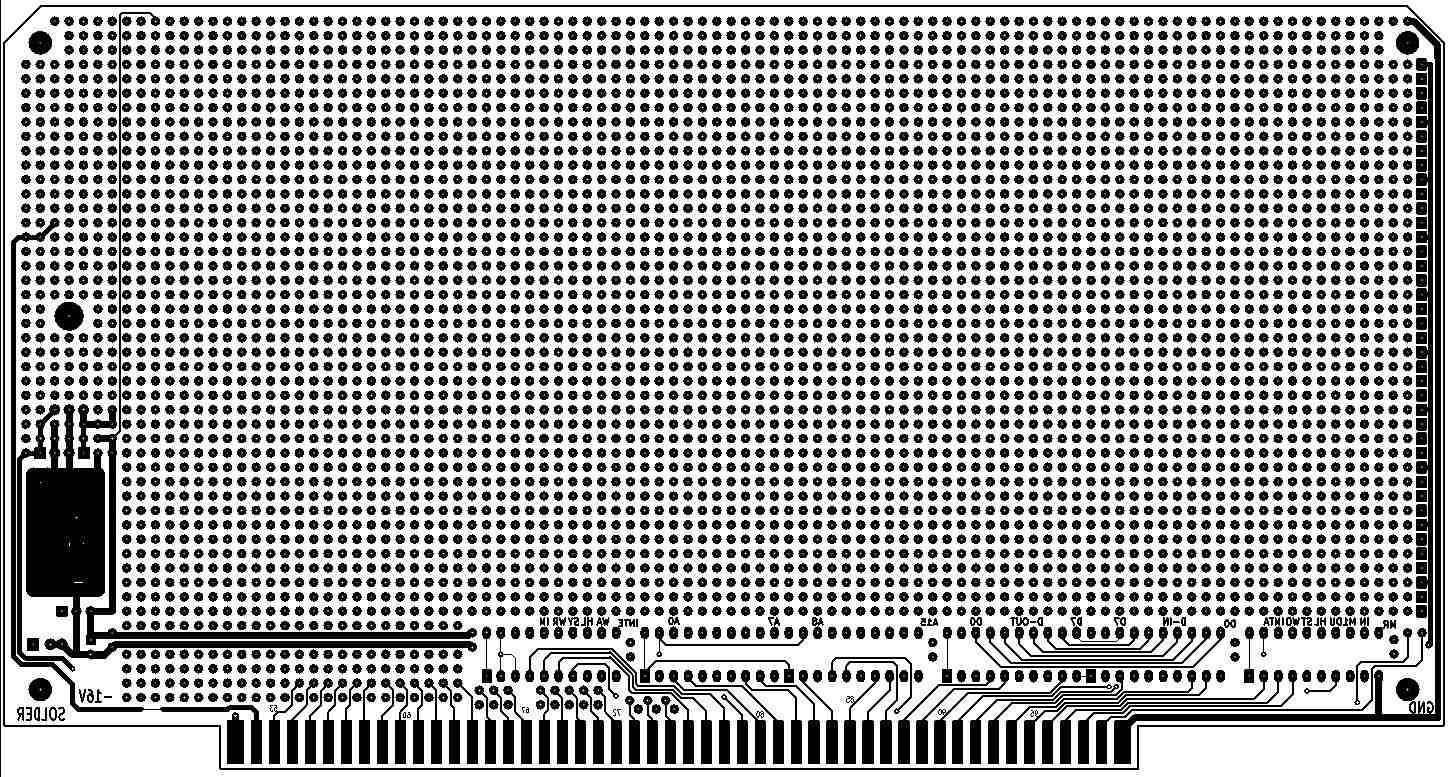

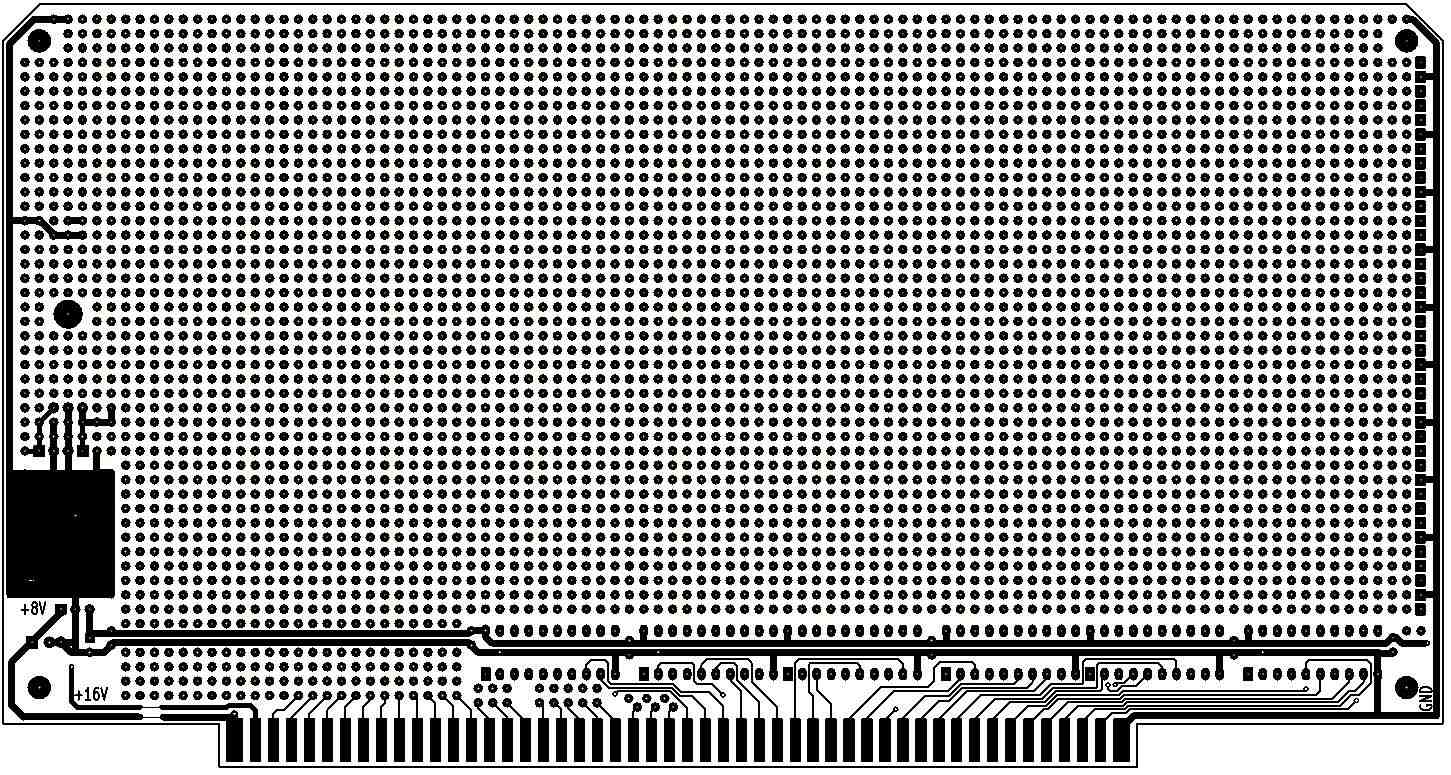

1. The 8mil traces had to be increased to 10mil so he could produce a "1oz copper" board. The alternative would be to keep the 8mil traces and use only 1/2oz copper. The problem with 8mil at 1oz copper is the copper is thick and the undercut may severely weaken the trace.

2. I had to move the ground trace away from the edge of the board. It damages the router bit he uses to cut the shape out. So I moved those traces in 15-20mil from the edge.

I also made some last minute cosmetic changes by adding labels to buffer chip pins on the copper side. I don't know how readable they will be under the solder mask, but we live and learn.

The boards will be ready in 3 weeks, normally he turns the boards around in 1 to 2 weeks, but there is a delay because he has some family matters to attend to.

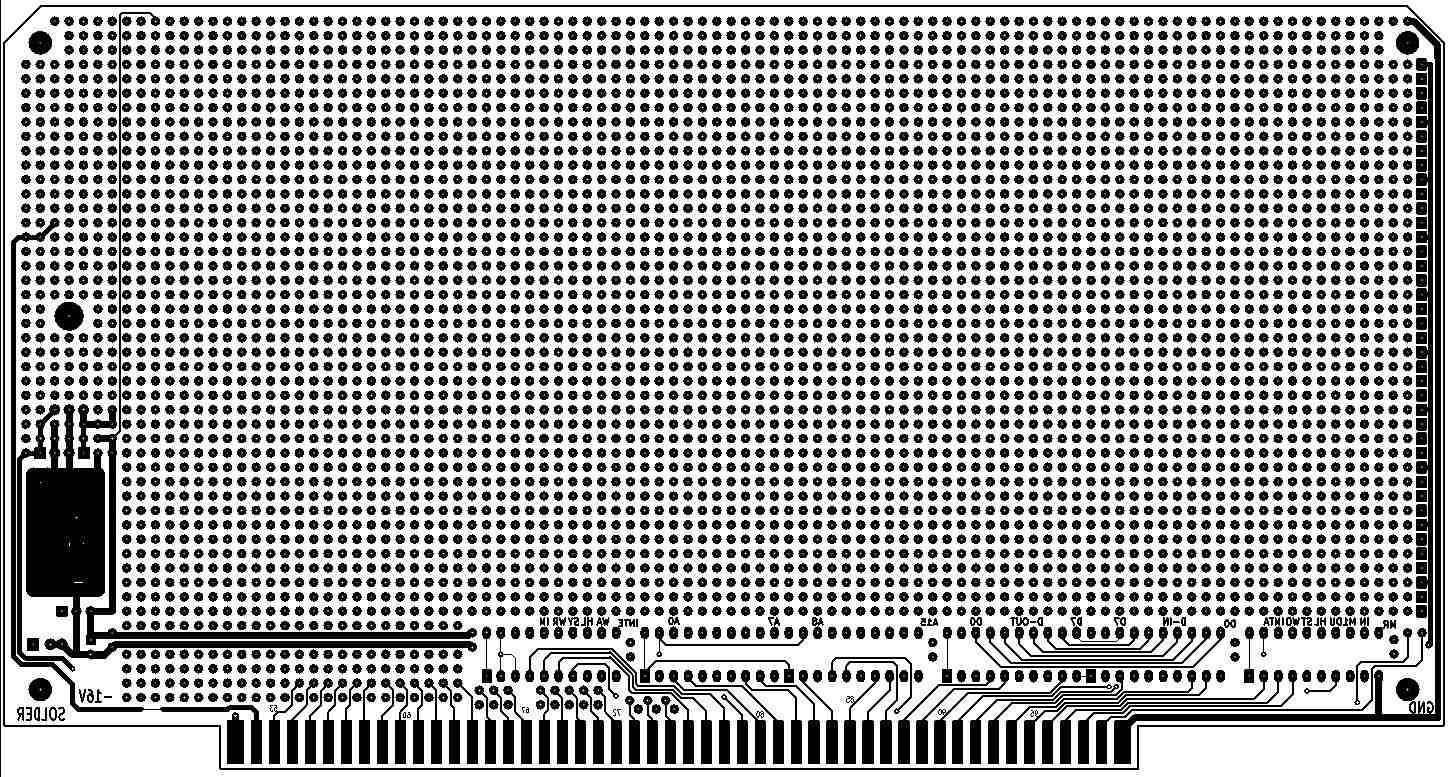

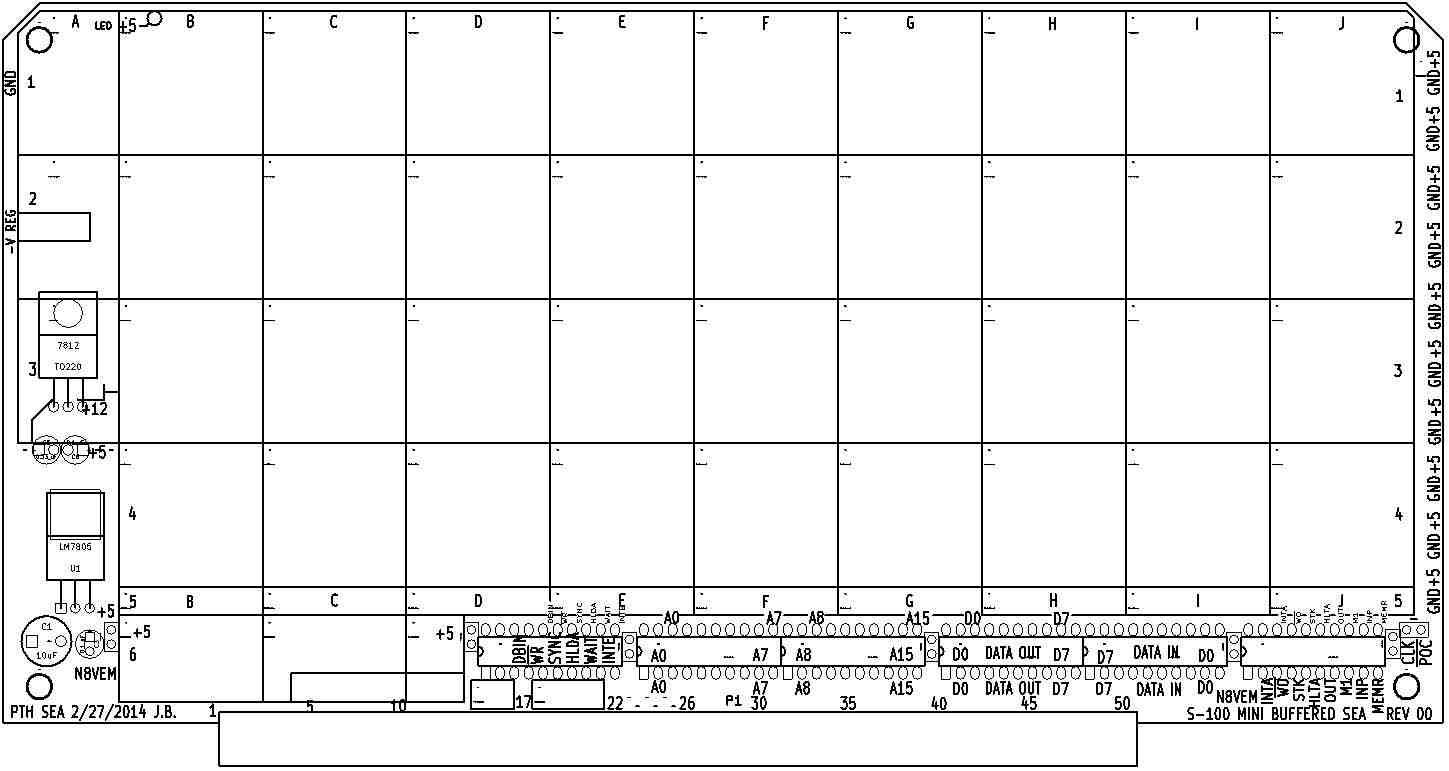

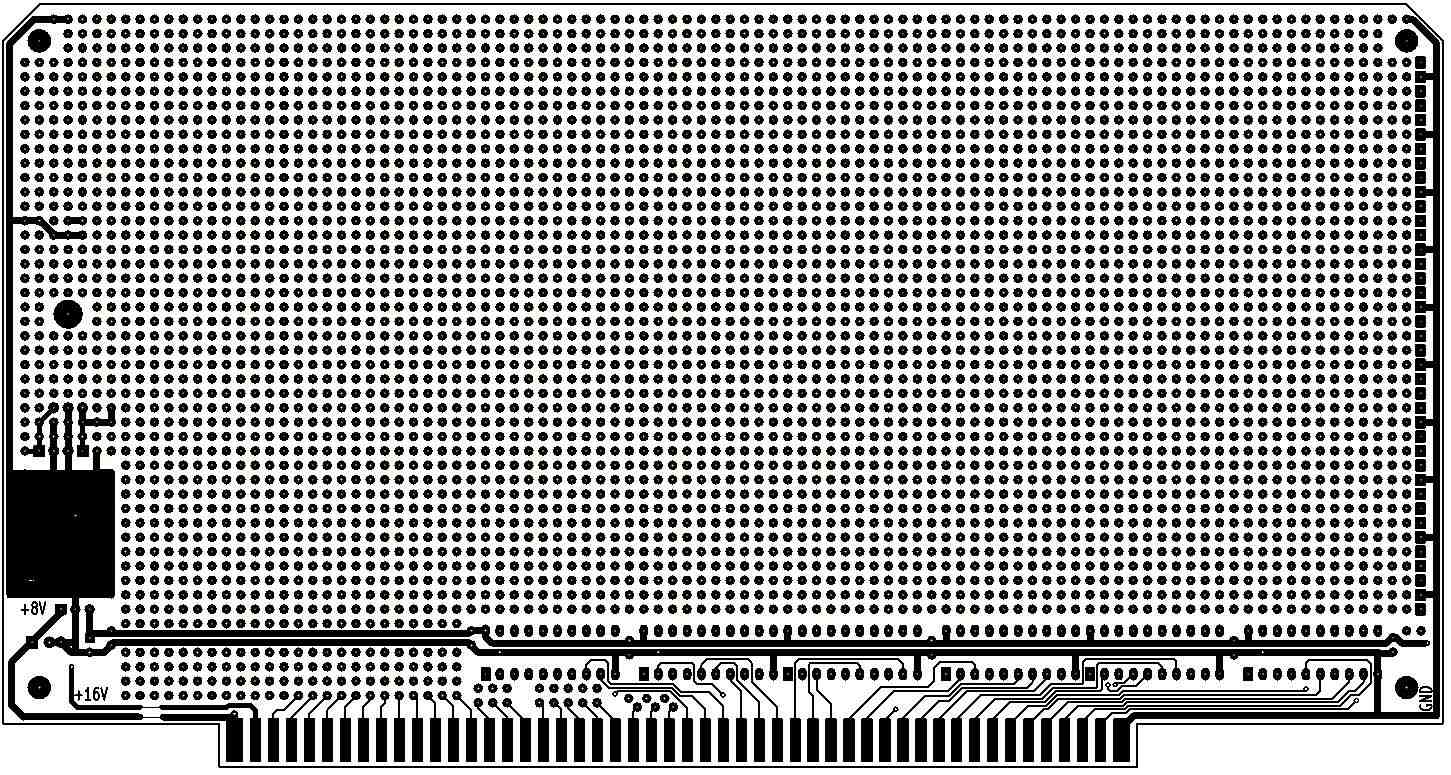

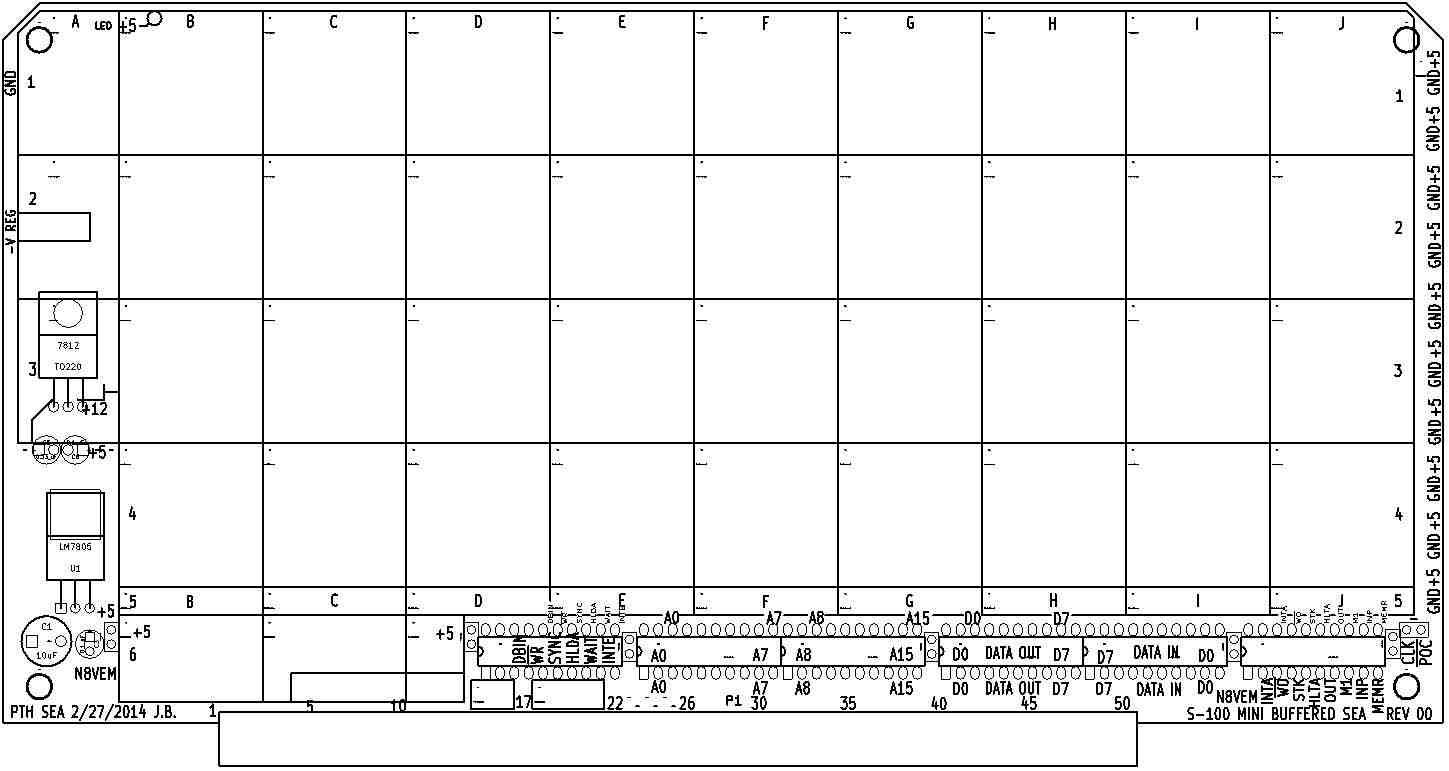

Here is the final submitted design:

1. The 8mil traces had to be increased to 10mil so he could produce a "1oz copper" board. The alternative would be to keep the 8mil traces and use only 1/2oz copper. The problem with 8mil at 1oz copper is the copper is thick and the undercut may severely weaken the trace.

2. I had to move the ground trace away from the edge of the board. It damages the router bit he uses to cut the shape out. So I moved those traces in 15-20mil from the edge.

I also made some last minute cosmetic changes by adding labels to buffer chip pins on the copper side. I don't know how readable they will be under the solder mask, but we live and learn.

The boards will be ready in 3 weeks, normally he turns the boards around in 1 to 2 weeks, but there is a delay because he has some family matters to attend to.

Here is the final submitted design: