I have recently starting doing surface mount chip soldering for or 16MB RAM and (future) VGA board. With practice it gets easier, but I would say if possible I would recommend sticking to chips/sockets. It’s easier to replace chips, make changes etc. also. Are you sure regular DIP’s will not fit on the board. With Freerouter the 74LSxx chips can be very tight with almost no space between the sockets. That is a simple board and should converge quickly.

John

From: n8vem...@googlegroups.com [mailto:n8vem...@googlegroups.com] On Behalf Of Crusty OMO

Sent: Wednesday, December 31, 2014 4:34 PM

To: n8vem...@googlegroups.com

Subject: RE: [N8VEM-S100:5933] SOIC Packages For S100 Boards - Survey Question

I'm good with it. But I know what people mean about eye sight. I just got my first bi-focals last year.

I'm just 48, but I imagine it gets worse not better. But everyone's eyesight is different.

But, here's my experience with SMT and some ideas. It is in many ways easier than through hole.

I've used professional reflow machines... but you don't need one. What I use is a butane soldering iron with a hotair attachment. In fact, when I'm in production mode, I use both in one hand. The hot air heat the next pin(s) while the hot tip iron finishes the job with solder coming in as fast as I can spool it. You can probably solder 4 pins a second like this. Anyway, back to smt. The trick to smt is to have a clean board, keep your fingers clean of oil or wear gloves, don't touch the parts with your fingers, use tweezers. The real trick is to use solder paste. Dispense a small bead across the pads, drop your chip on the right pins, as you heat the chip and solder, the chip will jump into the perfect spot as the solder flows. It was actually a bit of a surprise the first time I saw a chip jump, the surface tension of the solder will pull the chip to the right spot. I use the hot air from the soldering iron and blow it over the pins and just circle the iron around all the pins in a steady pace until the solder reflows. To remove a chip, just hold it with tweezers, circle your hotair around the chip a few times an it will just come off.

Pitfalls... holding a chip with tweezers might be harder for some??? perhaps there's some kind of suction cup holder tool? like the robotic tools, but manual?

Visual inspection. I've seen some amazing scopes, but I'm sure the price is equally big. My mid-range Canon camera does a nice job through it's view finder, I sometimes even snap a picture and zoom in digitally. I heard Jack Rubin got a cool end-o-scope for Christmas... perhaps he might share a performance review?

Last piece of advice... you can't get good at something by avoiding it... there's plenty of throw-away electronics out there with SMT parts you can practice on. The nice thing is that device is already dead! Let it give you something more before it goes to electronic heaven.

Oh, you can also use a hot air gun, but you will need to choke the air intake to get it a little hotter... not that I had to in mine, but you might have to bypass the safety thermal switch... the oven is another good option, if you can get the wife out of the house long enough... and don't tell her you've been baking electronics... before you know it, she'll blame you for finding a transistor in her cake.

Big piece of advice!!! These are very HOT temperatures. The board will look cool, but DO NOT touch it. Wait at least 5 minutes before examining, and perhaps some gloves might be helpful. A wet sponge can be used to test the board for "sizzle". Don't use it to "cool" the board, just as test. Finally, as a safety, always have a nice bucket of cold water with ice near by, If you do get burned, it will help if you hold your hand in cold water for 15 minutes. Also, with all this heat, something might catch fire... that bucket or a proper extinguisher might prove useful. Oh, that brings me to another point... last one, I promise. you will burn your desk or bench... I found a metal mesh fork and knife drawer organizer at the dollar store, turned upside down, it will save your desk from being burned.

Ok, I'm done with advice, good, bad or just ugly.

Regards,

Josh

Date: Wed, 31 Dec 2014 13:15:38 -0800

From: ilv...@gmail.com

To: n8vem...@googlegroups.com

Subject: [N8VEM-S100:5924] SOIC Packages For S100 Boards - Survey Question

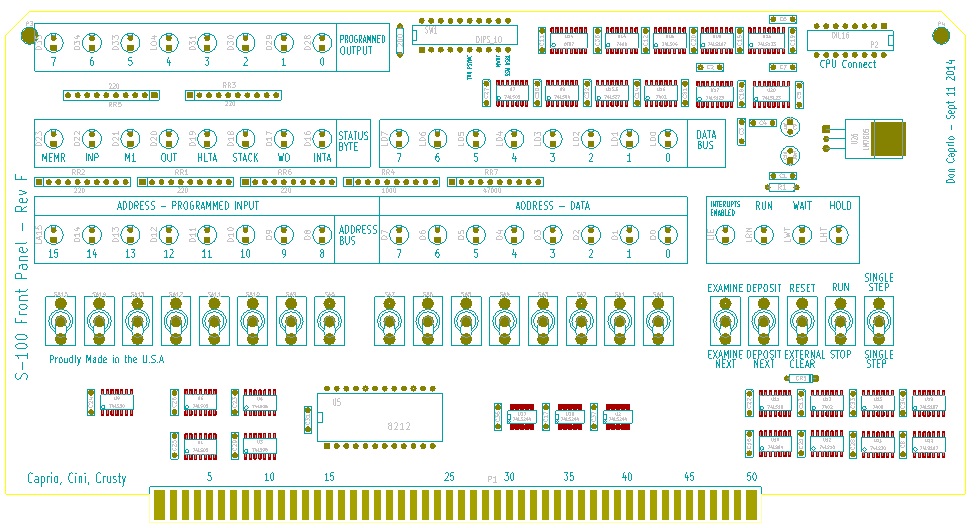

I'm curious how you guys feel about using SOIC chips

instead of the traditional DIP. Yes they are a bit more

difficult to solder up and don't have a socket for easy

replacement.

I was wanting to add additional chips and a 10 position DIP

switch to the FP mini design. However there is just not enough

room. I may be able to squeeze them in but it would be very tight

and fear there may be no room for traces.

--

Don Caprio

ilv...@gmail.com

--

You received this message because you are subscribed to the Google Groups "N8VEM-S100" group.

To unsubscribe from this group and stop receiving emails from it, send an email to n8vem-s100+...@googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

--

You received this message because you are subscribed to the Google Groups "N8VEM-S100" group.

To unsubscribe from this group and stop receiving emails from it, send an email to n8vem-s100+...@googlegroups.com.

For more options, visit https://groups.google.com/d/optout.